.218 Mashburn Bee

The "Improved" Bee

other By: Stan Trzoniec | February, 26

There were some good designs that now you only read about in faded, dog-eared tomes of the past – those like the 2R Lovell, .22 Niedner or even the line of .22 Miller magnums. They were good because their inventors said they were, but at that time gunsmiths were seemingly hidden away in back shops all around America, and since we didn’t have the media exposure we do today, and unless you could get a following, all was lost.

Being a big fan of .22 centerfires, I’m always on the lookout for same from custom gunmakers or commercial outlets. Most rifles can be found in the trade papers that run hundreds of ads for used guns, new guns and specialized services. This one, however, came from the folks who built a tack-driving .221 Fireball for me a few years back. Cooper Arms (3662 Hwy 93 North, Stevensville MT 59870) is becoming known for preserving wildcats from the .17 Squirrel to improved versions of the .257 Roberts. Dan Cooper sent a new catalog, something dyed-in-the-wool wildcatters should have, and once I saw the selection, I was hooked.

The company has several actions set up for different cartridges, lengths and rifles. My particular favorite is the Model 38, which can house all the really neat wildcats like the .17 Ackley Hornet, .17 He Be, .19 Calhoun and the .218 Mashburn Bee. For the varmint folks, you have a choice of versions that include the varmint-type rifle complete with a heavier barrel and flat forend stock. Those who like the more classic type rifle can order theirs in the Classic, Classic Custom and Western Classic complete with a variety of options to include a skeleton grip cap, skeleton buttplate and checkered bolt knobs, among other things. Wood is anything from AAA select Claro walnut to AAA French walnut.

The first thing you’re going to notice about Cooper’s “varmint” series is that they don’t feel like those big, clunky varmint rigs you may have used in the past. Sure, there is a wide forearm, but it is designed to be a working part of the rifle and not a hindrance. Inside, you find the inletting of the rifle perfect; one thin sheet of paper will fit between the forend and the free-floating barrel.

There is no Monte Carlo or cheekpiece on the stock, and the line of sight between shooter and scope is right on. The pistol grip has that just-right downward turn for prone shooting and is finished without a grip cap on this model. Point checkering is included, as is a rubber buttpad for non-slip performance in the field.

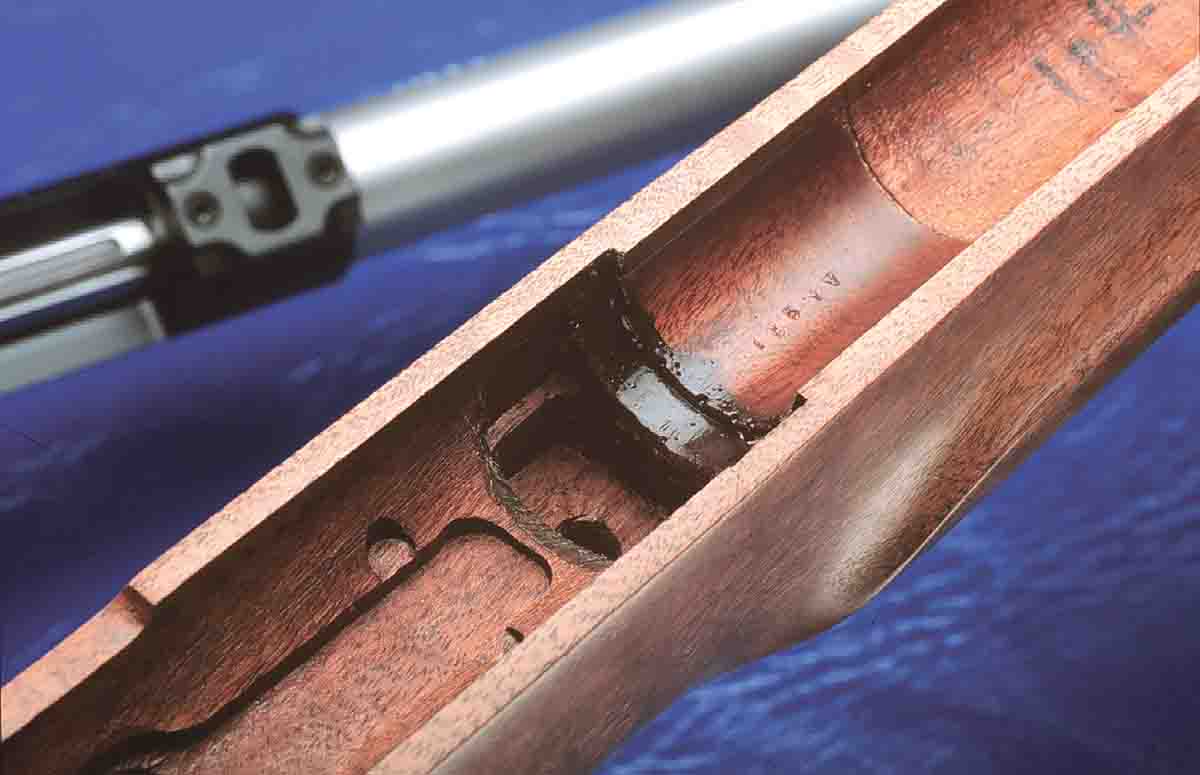

The action is the heart of any rifle, and Cooper’s version is glass bedded about the recoil lug. Barrels are air-gauge inspected and match-grade quality. The bolt has three lugs, and the trigger pull from the factory was set at 21⁄2 pounds without any hint of slack or creep. The action is single shot and includes an innovative feed ramp. It is set up to move in a rocking fashion as the cartridge is fed into the breech. In this way it will move when the bullet, shoulder and cartridge move into the chamber, giving the action an uncanny smoothness. In fact, this altered ramp will even feed empty cases into the breech to check for the final headspace and bolt resistance on a sized case before getting set up for loading. Finally, the safety is rearward of the bolt handle, and scope bases (included) accept all the commercial rings in Redfield-style bases.

For optics, Leupold had recently introduced its Competition Series in 35x, 40x and 45x, all with 45mm objective lenses that feature 1⁄8 minute-of-angle (MOA) click adjustments, side focus parallax adjustment and 30mm main tubes. Lenses are multicoated and available with either a crosshair or 1⁄8-MOA target dot. Being high-powered glass, they do need attention when settling in, as the field of view is not as generous as those on lower-powered scopes. This is not to single out Leupold or its design; this is something that is common on all high-powered scopes and should be taken into consideration before a serious purchase is confirmed. One should be savvy to anything before laying down hard-earned cash. I opted for the 40x.

The .218 Mashburn Bee

Like the .22 Hornet and .22 K-Hornet, the .218 Mashburn Bee is easy to form as long as you have a rifle to do it in. Just pop a .218 Bee into a .22 Mashburn Bee chamber, pull the trigger and, voilà, you have a new cartridge. Of all the so-called Bee versions of improved cartridges, the Mashburn moves the shoulder forward quite a bit, but while fireforming over 200 cases, I found that neck and mouth splitting were held to a minimum if the rifle has correct chamber dimensions. I had four that split at the shoulder and two of them had twin splits within close proximity of each other. Annealing in all probability could help, but for only four cases (around 2 percent), I didn’t think it was worth the effort.

For a shopping list, purchase at least four boxes (200 cases) of factory ammunition or .218 Bee brass. I prefer the factory ammunition as this makes fireforming much easier in the initial stages of load development. Winchester is the sole supplier of brass and the only firm that produces it on a semi-regular basis. Next a full-length die set is in order simply because the rifle will be forming it for you. I had RCBS forward a set of its number 56030, which is in the G group. The shellholder is RCBS No. 1 and Small Rifle primers like the CCI 400, BR-4 or Remington 71⁄2 Benchrest will fill the bill. No magnum primers are needed here, even if the weather turns cold.

With an ample supply of fired cases, I smoke a couple of cases with a candle so I can monitor the progression of the die as it works its way down the case neck. Then the die is secured to size the whole batch of cases. One nice thing about the improved Mashburn is overall length without the bullet measures the same as the parent .218 Bee – 1.340 inches. After fireforming for the Mashburn, don’t be surprised if the case turns out to be only 1.320 to 1.322 inches in length. This is not surprising, as most “improved” cartridges are a bit shorter than the parent case after fireforming.

When working with a small case like the Mashburn, it’s a good idea to use the case lube very sparingly. The right amount of lubrication on the case should feel slightly tacky; anything more will lead to shoulder dents and/or neck splits. After running a bunch of cases over the pad, place a small amount of case lube between your forefinger and thumb and go around the neck, keeping the lube at a minimum. Using a Q-tip, place a small amount of lubrication on the inside of every fifth case to aid in the withdrawal of the expander plug as it exits the case. With this technique, you’ll wind up with no damaged cases or dents when sizing.

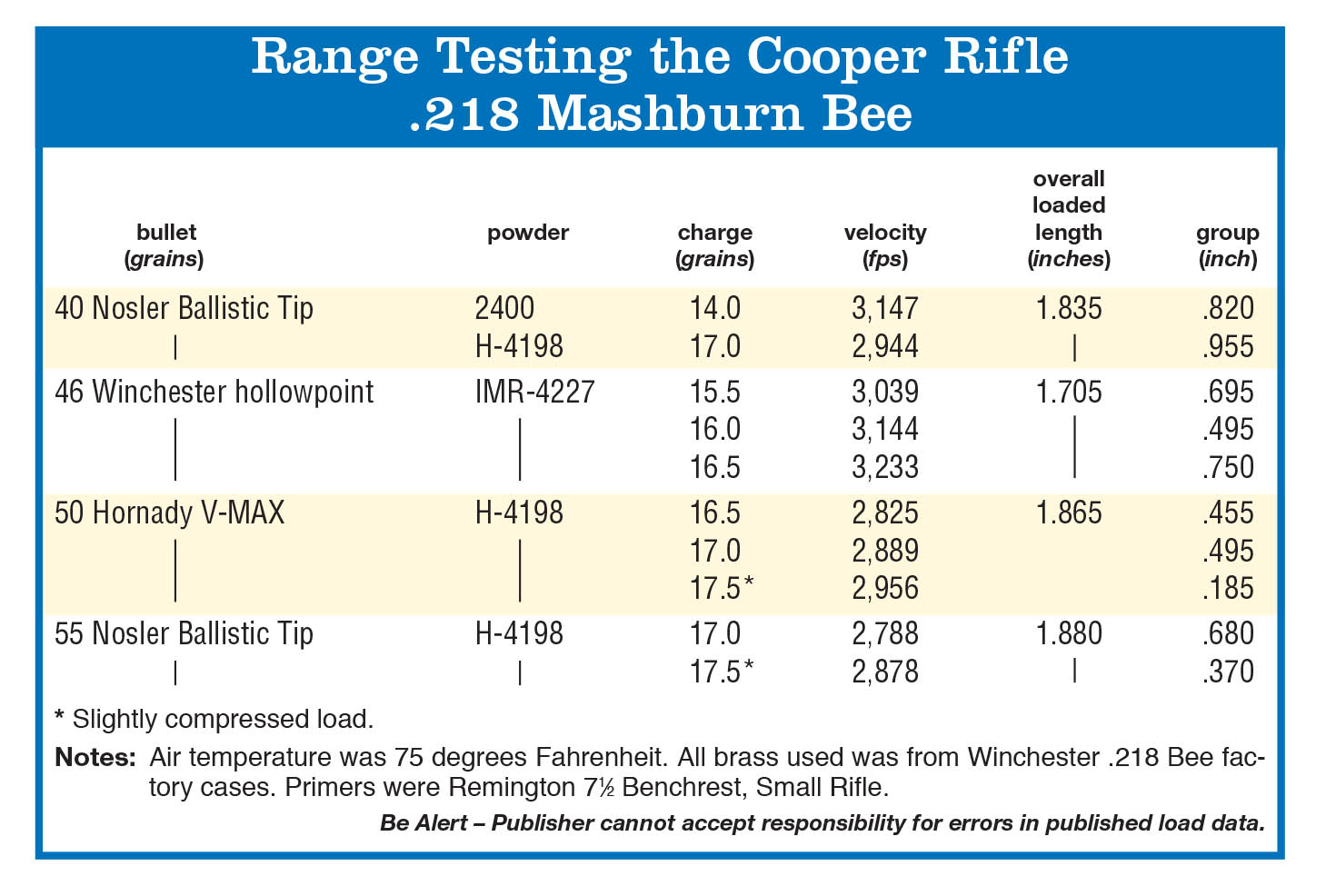

Finding loads for the .218 Mashburn Bee took some research. While it does match the 2R Lovell, I like to find actual data pertaining to the cartridge I’m working with even if one closely matches it. To do otherwise would be foolhardy, especially when reloading ammunition. Vintage books from authors like F.C. Ness, C.S. Landis, Parker Ackley and briefs from our own Ken Waters helped to define the parameters of this Mashburn and set me on the right track. If you don’t have access to any of these, starting out with basic .218 Bee data will put you in fine shape with room to grow upward to around 10 percent for starters. The data listed is safe, accurate and gives velocities that go hand in hand with the volume and overall size of the .218 Mashburn Bee at responsible distances.

When loading small capacity cases like the Bee, care should be taken to see to all the details. For instance, some of the powder funnels made today seem to be just a little large for .22-caliber case mouths and especially for those with short necks. When this happens, small amounts of powder will fall outside the case. This can easily be verified by checking the inside of the tray you are using. Sometimes it can be as much as a full grain. The remedy is to use a .17-caliber funnel to make sure all the powder winds up in the case.

Volume with different powders showed that 2400 filled the case between the shoulder and neck with 14.0 grains. Using 17.0 grains of H-4198 placed the powder volume halfway up the neck. On the other hand, 16.5 grains of IMR-4227 was easier to use and because of its almost spherical qualities (as opposed to the stick type H-4198) filled the case to the neck/shoulder juncture of the case. Some of the loads that run upward of 17.5 grains of H-4198 filled the case to the brim and were compressed, but I had no problems seating any of the bullets from Hornady or Nosler.

Bullets ran from the almost petite Nosler 40-grain Ballistic Tip to the 46-grain “Bee” bullet from Winchester. This is the same bullet used in factory loads sans the cannelure. From here I filled out the list with Hornady’s 50-grain V-MAX, which is a favorite in just about all my .22-caliber firearms, and the ever popular Nosler 55-grain Ballistic Tip. I have also listed the overall loaded length, which is the length that is comfortable in the Cooper rifle and allows the full neck length to grip the bullet.

In the 46-grain offerings, I used the Winchester “Bee” hollowpoint. With IMR-4227 I varied the loadsby .5 grain, each starting at 15.5, 16.0 and 16.5 grains. With the first selection, groups ran .695 inch at 3,039 fps. (This compares favorably to a load in the 2R Lovell that was quoted at around 3,260 fps.) With 16.0 grains, groups shrank to .495 inch with a mean velocity of 3,144 fps. Ackley quotes 3,242 with this same load. Finally, with 16.5 grains of IMR-4227, velocity increased to 3,233, but accuracy did suffer at .750 inch. Since I started to see the beginnings of an extractor burnishing on the case head, I backed off and was more than happy with 16.0 grains. It’s more accurate anyway. Ackley published this load at 3,319, so again we’re close.

The 50-grain Hornady V-MAX was teamed with H-4198. With a starting load of 16.5 grains, groups fell into a boring routine of less than .5 inch at 100 yards. Seventeen grains did the same (around .495 inch), but when I turned to 17.5 grains, things did an about-face. This is a slightly compressed charge, so don’t panic when you fill the case. The bullet seats easily, meaning there is a lot of air in the case with this propellant. This load at 2,956 fps turned in groups that averaged .185 inch – very impressive for a cartridge everyone seems to have forgotten. For the record, Ackley in his tome relates this load produced just about 3,300 fps. In the more common .218 Bee, I’ve gotten velocities of around 2,500 fps with groups that went slightly over an inch in a Ruger Model 77 with a 26-inch barrel.

Turning to Nosler again, I used its 55-grain Ballistic Tips. With 17.0 grains of H-4198 groups measured .680 inch with velocities around 2,800 fps. The final load of 17.5 grains was slightly compressed, hitting 2,878 fps (Ackley publishes this at 3,316 fps) with accuracy at .370 inch. I’ll take that any day.

The Cooper rifle and the improved Mashburn performed well time after time. The rifle is a joy to carry around considering it is a “varminter,” and combined with the Leupold 40x scope and a pocketful of Mashburn cartridges, it would be a great way to spend many a day stalking varmints in any part of the country. The loads took some time to research as not to err on the wrong side and, considering the effort, expense and fun, were indeed worth every minute.

To me any wildcat is worth it simply because you’ve separated yourself from the rest of the pack and struck out on your own. The .218 Mashburn Bee is a great place to start.