Bullet Damage!

Does it Matter

other By: Chub Eastman | February, 26

One cold winter night in mid-January when the moon was full, a long discussion was held concerning the “what would happen” and “have you heard” scenarios. When the new plastic-tipped bullets hit the market a few years ago, most of the advertising touted increased accuracy, downrange performance and a wind-defying flight to the target. The sales pitch with the new plastic tips centered around the idea that the noses of the bullets wouldn’t get banged up and deformed while riding out the effects of recoil in the magazine when the rifle was fired. With banged up and deformed noses, the bullets would be inaccurate and wouldn’t fly straight.

That’s what was suggested, but is that what really happens? This was the subject of the discussion on that cold winter night. The project was spawned to see what real effect the shape or “misshape” of the bullet nose does have and how it would affect performance in the field under normal hunting situations. Accuracy, ballistic coefficient and velocity are all in question when something happens to the front of the bullet.

To simulate various recoil effects on the noses of the bullets, one series had the lead point clipped off down to the jacket. Next the tip was hammered flat to where it resembled a mushroom. The third series was put on a grinder, and a 45-degree cut was ground down far enough that a portion of the jacket was also cut. A fourth series of loads was tried for no other reason than to see what would happen. The bullets were not altered in any way but were loaded backwards.

The question came up during the planning of this test as to what would happen if the front of the bullet was not altered but the base of the bullet was deformed in some way. With this in mind a series was loaded with a notch cut in the heel with a file.

The one thing that should be understood before any conclusions are drawn is ballistic coefficient and what real effect it has on bullet performance in normal hunting situations. Ballistic coefficient is not a hard number like sectional density, foot-pounds of energy or lock time.

The official definition of ballistic coefficient is the ratio of a bullet’s sectional density to its coefficient of form, used to describe the bullet’s effectiveness in oncoming air resistance during flight. It’s measured by its time in flight over a given range. What makes it a nebulous number is that results can be affected by altitude, humidity and air temperature. It’s a number used to calculate bullet trajectory over a given range so you have an idea of what the bullet will do. It still depends on altitude, humidity and temperature as to what the bullet will actually do. Mike Venturino reviewed this subject a few issues ago to show the difference in bullet shape, concluding that ballistic coefficient should not be a big concern over normal hunting ranges.

The load used for the testing was 54 grains of W-760 in Winchester cases with a WLR primer. Seating depth was set at the SAAMI maximum overall length of 3.340 inches with the exception of the bullets loaded backwards, which were seated so the base of the bullet was set at the same position as the start of the bearing surface of bullets seated like they were intended.

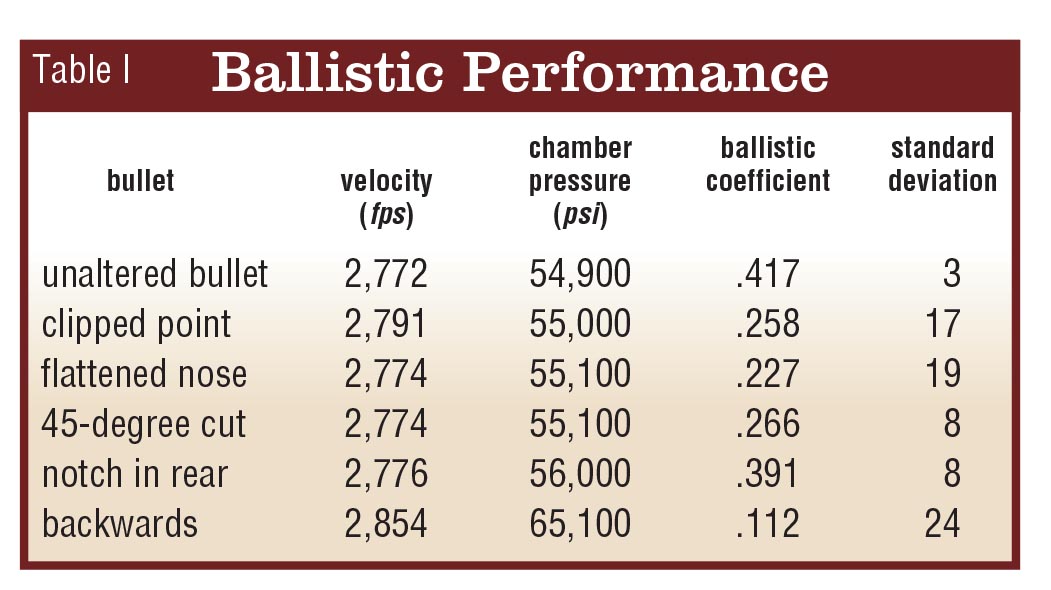

The first series shot across the chronograph was normal loads with no alteration to the nose or base of the bullet. This was the load others would be compared to. Table I shows the variation in each of the different series of loads. All were very close with the exception of the bullets loaded backwards. Here the chamber pressure was beyond the safe limit. This problem could be attributed to the bullet being seated so deeply in the case that it occupied a considerable amount of case capacity. The other

With all the essentials covered, it was time to head for the range. Needless to say it raised a few eyebrows when a couple of bystanders took a look at what was on the shooting bench. Something about crazy gun writers was mumbled as they headed for the other end of the firing line. I don’t think they appreciated all the hard work and dedication it took to do something like this. Besides they probably don’t appreciate what it takes to be a card-carrying loony.

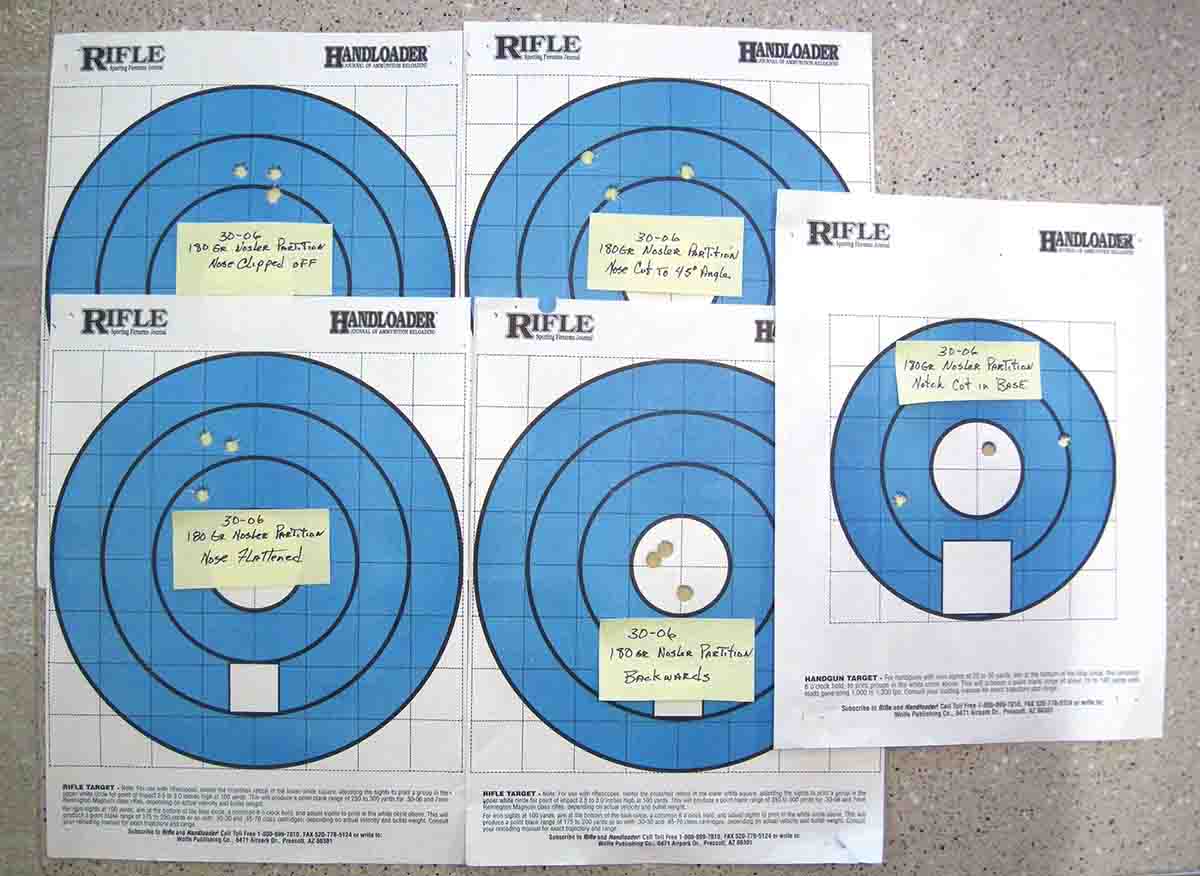

After the range session, the targets were collected for comparison. The point of impact was basically the same for all the different series with the exception of the backwards-loaded bullets. This difference could probably be attributed to the reduced powder charge used to reduce pressure.

Accuracy for each of the series that had something done to the front of the bullet was very good and in line with a standard unaltered load. The one flyer from the 45-degree cut bullet load was a called shooter error. I guess that proves I can’t be perfect all the time.

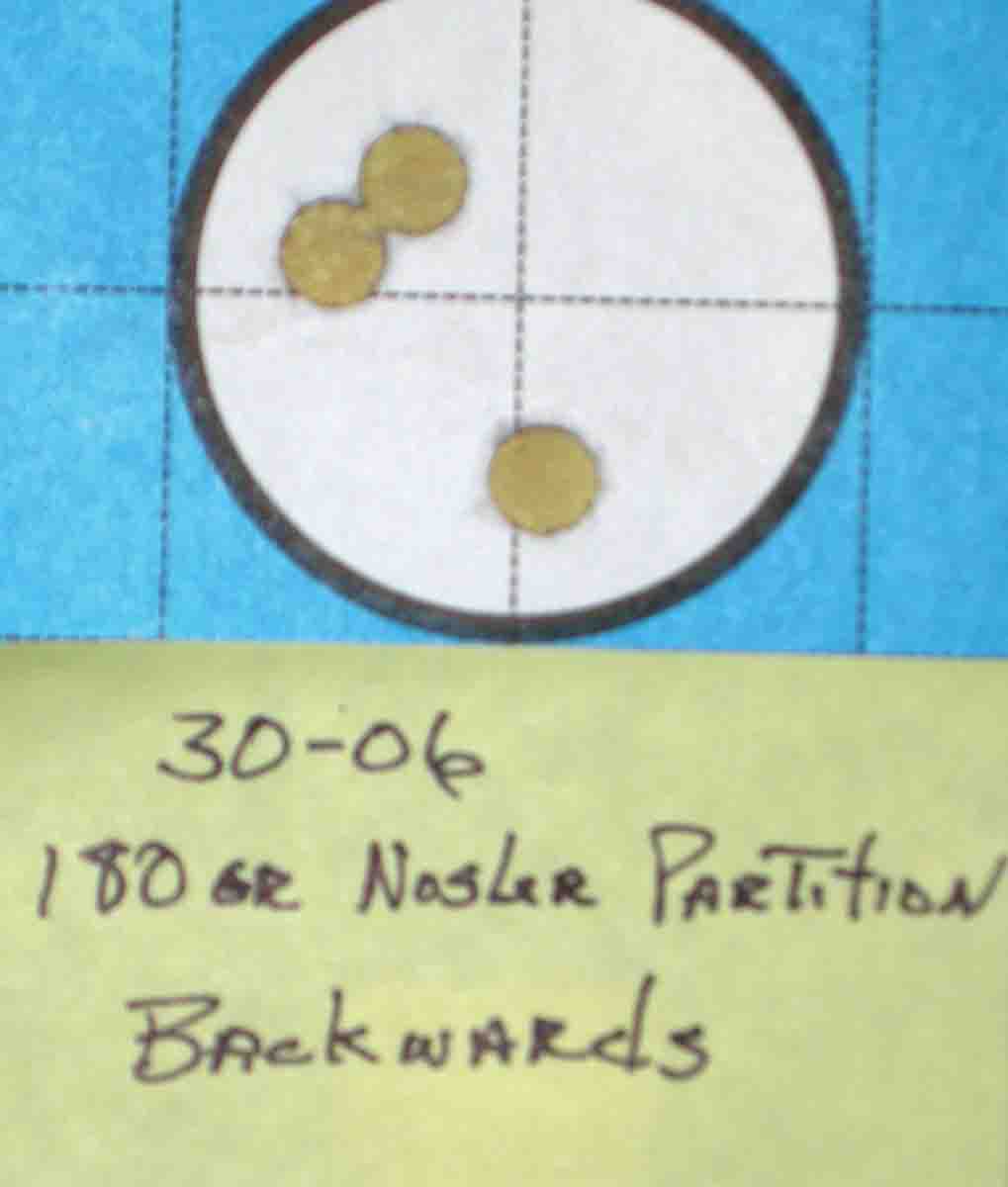

When targets were examined, two noticeable results stood out. The first was the holes from the backwards-loaded bullets looked like they were shot with a wadcutter. Not surprising when you think about it. The other was the group shot with the notched heel bullets. Accuracy was nonexistent, and if you look at the bullet holes closely, it is evident the bullet was yawing or had a wobble to it as it went through the target.

The results of this project brought a couple of things to light that dispelled and answered questions about bullet flight and what affects it. Basically it proved you can do most anything to the nose of a bullet, and it won’t have much adverse effect on accuracy or performance, even if it is loaded backwards. Do something to the rear of the bullet, and it is all over the place. This can probably be attributed to the fact that when the bullet exits the bore the gas seal around the circumference of the base is not equal or consistent, as gas exits where the notch has been cut. This would cause an inconsistency in pressure against the base of the bullet, causing it to yaw as it exits the bore.

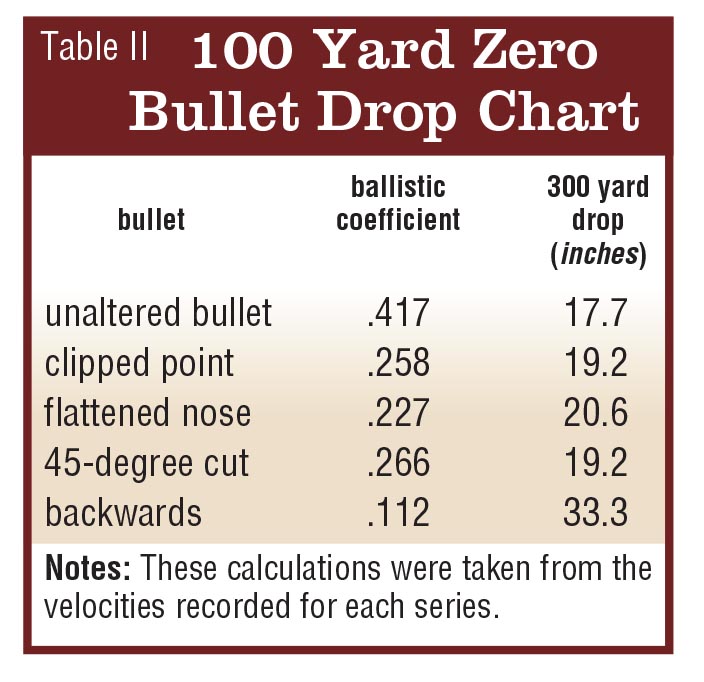

There seemed to be quite a bit of variation in the ballistic coefficient with each series of loads. Then, too, it doesn’t really make that much difference in normal hunting situations. Using a standard atmosphere ballistic table with the zero set at 100 yards, Table II shows there is not much difference in point of impact out to 300 yards. I doubt most hunters using a shooting position normally used in the field could recognize the difference in point of impact. However, if one is inclined to shoot bullets backwards, he might want to keep shots under 200 yards.

I guess it all boils down to not worrying about the second or third shot if the nose of the bullet gets banged up a little in the magazine. Just don’t put a nick in the base of the bullet when loading for your next hunting adventure.