Handloading for the Autopistol

other By: Stan Trzoniec | February, 26

While all this sounds too good to be true, for starters, there are guns out there for everyone. Semiautos come in all shapes and sizes ranging from petite models to those holding copious amounts of ammunition in double stack magazines. Accessories from holsters to special sights are there for the asking, but for fuel, ammunition is a big part of the equation. If you are a casual shooter, or want the convenience of factory loaded ammunition, then head to the nearest sporting goods store or gun shop. Today’s list of commercial ammunition seems to be never-ending ranging from squib, target or full house defensive loads. Get a catalog; go through it and pick something that will suit your needs – it’s that simple.

On the other hand, reloading ammunition for the autopistol takes some time and effort. Sure, straight sided ammunition for a revolver needs dedication, especially with the overall length of the cartridge to make sure the bullet never protrudes past the face of that revolving cylinder. Without the ability to cycle the gun simply because of a light crimp or the wrong overall length, could add up to a tragedy especially when facing dangerous game or a misguided individual downstairs in your home in the dark of night.

On the other hand, autopistols dote on ammunition that is 100 percent reliable to function in the gun while being accurate enough for the job at hand. They have to. A malfunction in the gun when it comes to feeding is not the right way to start a confrontation especially when your life is at stake. Sticking to the details of loading will make the ammunition fully dependable and reliable no matter the gun or caliber.

Overall, I guess if I had to focus on one word in handloading ammunition of this type of gun, it would be “consistency.” In the beginning of the autopistol craze, I recall shooters taking the gun and placing it on the side simply because it would not shoot right. Many were slow to transition from a revolver to the auto because if the wheel gun would not fire, cock the hammer or go to double action, move to the next round and let go. At that time, I saw frustration in many shooters who, by not following certain guidelines for loading, got tired of the gun and went back to the revolver.

To begin the loading for a new gun, purchase a good quantity of new brass. New formulas in metallurgy have brought the status of the brass case to its highest level and products from Remington, Federal, Winchester and independents like Starline, offer top quality brass at reasonable prices. In this way, with a new gun and new brass, tracking the end results is easy as you make your way down the path of loading premium ammunition. If your budget is tight, once-fired brass is a good alternative, just make sure you are getting what you paid for, which amounts to a clean product, perhaps sorted by headstamp and without defects. Additionally, when purchasing new brass, plan on quantity. Three hundred to 500 is a good move and check the end flap on the boxes, making sure you have the same lot number. That’s important.

I have been asked, “Why not size those cases first, and then clean them?” That’s a good question, and if they fall into the new category, go ahead and send them through the sizing die, prior to loading. However, when it comes to once-fired, it’s always a good idea to clean them up-front rather than taking a risk of scratching or ruining a standard die set with something that may have been lodged into the side of a used case.

Before we get to use a new die set, we have to purchase one. Like everything else in this world, choices are many and could be confusing if you don’t do your homework. Let me cite a few examples by just exploring the Redding catalog for example. While I am not going to explain all the variations, let me say that Redding – like RCBS, Hornady or Lyman, – offer many specific dies to include the most practical Titanium Carbide Die Sets that will appeal to a wide range of our applications from the .32 ACP to the .45 ACP in a three-die version, all without the drudgery of lubing cases. From here, you can move into the Competition Pro Series Die Sets, a separate Bullet and Seating Die with a built in micrometer, taper crimp dies for auto cartridges and a long list of accessories from presses, trimmers and even lead bullet moulds for lower or indoor practice loads if desired. One tip when purchasing a die set – even if the seating die includes a taper crimp within the body, order a separate one. I will explain shortly.

The sizing-decapping die is perhaps the most important in the set as it serves a twofold purpose. First, with this die, we true up new cases (mouth, body) and/or resize once-fired cases. On the upstroke where the case enters the die, it brings the case back to factory or The Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI) specifications with reference to the inner and outer diameter of the case in the shell holder. Next, it will deprime the case making it easier to clean the case fully in the tumbler before moving on. Any additional touching up the primer pocket for debris after tumbling can be handled with a small hand tool if necessary.

When using the sizing die, it’s important to check the inner dimension of the case with regards to the outer dimension of the bullet, as the proper tension of the bullet to the case is an important part of the loading sequence. Using the .38 Super as an example, inside measurement of the case mikes out to .352 inch; right for a .38 caliber bullet of .355 inch for that cartridge. This tension, when combined with a taper crimp die on final assembly, will hold the bullet from being driven down into the case during feeding, which could cause a malfunction or worse yet, drive up pressure.

The next step is to carefully monitor the expansion or belling of the case mouth to receive the bullet. This is the second die in the series and removing the “plug” shows a round leading edge with a taper near the top going to a blunt stop. Measuring the body of the expander should come to a few thousandths of an inch smaller than the bullet diameter for a good fit into the case. Actually, it’s the top of the case we are interested in, so threading the die down into the press, put a case into the shell holder and move it up and down until you get a very minute flare at the top of the case. This is used to ease the bullet into the case without any cracking or splitting around the mouth. A good way to check is to place a bullet on the flare and looking at it should just sit perfectly on the top. Additionally, this is a good time to prime your cases. On the downstroke of the press after the flare has been established, prime the case all in one motion.

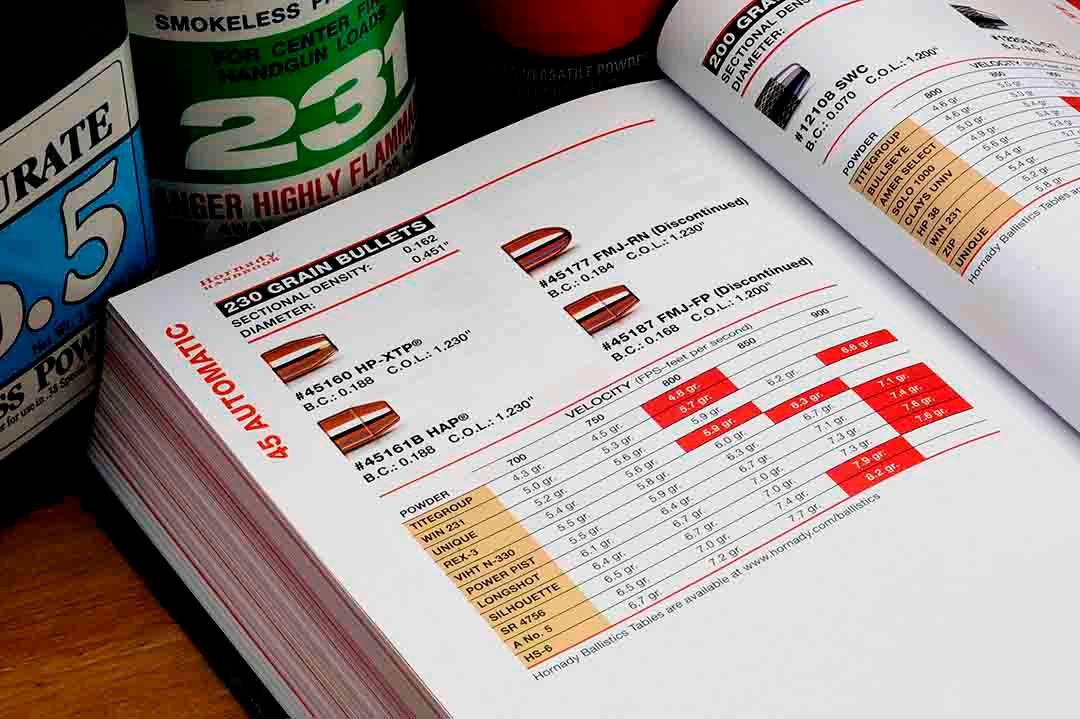

When it comes to powders, small cases need faster burning propellants to offer a quick recoil response to cycle the gun. Looking back on experience, I find the likes of Bullseye, Winchester 231, Unique and Accurate No. 5 or No. 7 to fill my needs with Hodgdon’s HS-6 a perfect fit to the .38 Super. In some situations where charges can be as small as 4.5 grains of Bullseye, the loads might fill half of the parent case, so it’s a good idea to load a tray, and then check each case with a pocket light making sure there are no double charges. In addition, back off from so-called “full power” or maximum loads for most of your shooting as they will just batter the shooter and gun in short order.

With the powder charges all set, seating the bullet is next and while I’m not going to go into a list of bullets for each cartridge, make your choice dealing with target, hunting or defense. Loading manuals cover all this with aplomb, as they want you to purchase their bullets. Before seating and with your bullet choice narrowed down, check the manual for the overall length of the cartridge with the bullet installed, as this is important to proper functioning of the weapon.

Bullets installed to the proper depth, it’s time to taper crimp. What I like to do is to crimp in a separate operation (with an additional die) as this lessens the chance of not doing this operation correctly because of the pressure on the bullet of seating and crimping at the same time. Seat all the bullets first, and then move them over to the crimping die. The proper way is to crimp the bullet is when you hold the finished round up to the light you can see a distinctive inward taper of the case to the bullet. This is the perfect crimp and assures 100 percent reliability if you did everything right up until this time. Finish up by inspecting each round placing them in your range box for shooting.

Modern autopistols are made for shooting and it boils down to the ammunition in the magazine. Handloading is the perfect way to insure that each round will cycle in the gun while still being accurate downrange. If you followed the rules and are meticulous at the loading bench, fun, not frustration will follow you throughout all your shooting adventures.