Handloading the FN 5.7X28mm

other By: Brian Pearce | February, 26

Development of the FN 5.7x28mm began more than 20 years ago and was first introduced in a submachine gun for military applications in the early 1990s. A tactical handgun followed in the late 1990s, and by 2005 a civilian version appeared. The cartridge is advertised to push a 27-grain lead-free bullet at 1,950 fps, a 28-grain lead core bullet at 2,050 fps (now discontinued but will return in 2010 due to demand) and a 40-grain lead-core Hornady V-MAX bullet at 1,700 fps.

The current civilian tactical handgun, known as the Model Five- Seven USG, is an autoloader with a 20-round capacity. It is constructed of polymer with appropriate parts being alloy and steel. Sights are fully adjustable. Barrel length is 47/8 inches, and weight is around 24 ounces empty.

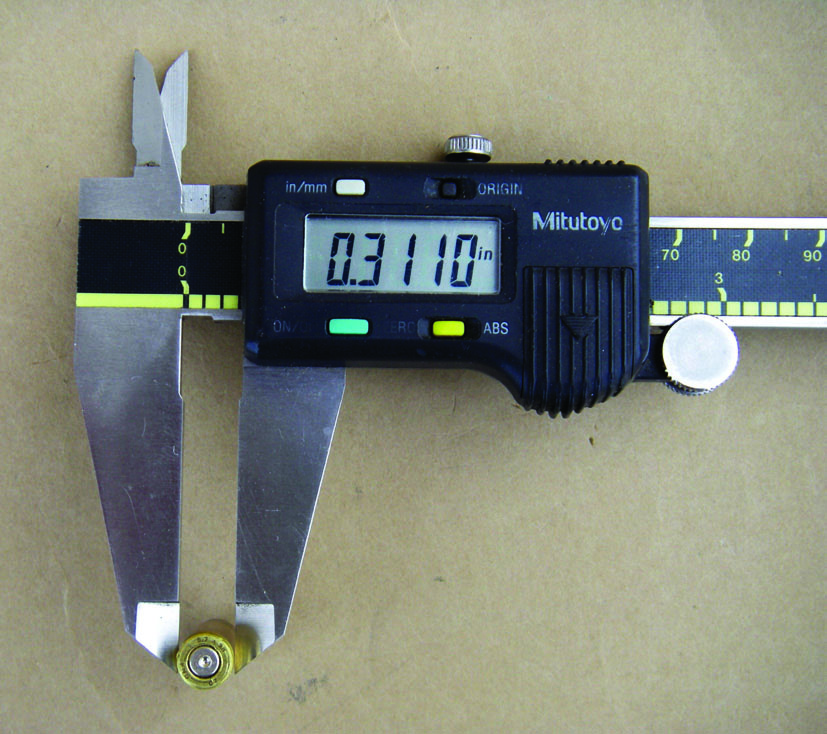

The 5.7x28mm cartridge is a bottleneck design that utilizes .22-caliber (.224-inch) bullets. The shoulder angle is 35 degrees. Water capacity (measured to the bottom of the neck) is 11.1 grains. It is a proprietary cartridge, so there are no pressure guidelines or industry standards for handloading. Clearly FNH USA (www.fnhusa.com) would rather sell ammunition than encourage handloading that would produce ammunition for a fraction of the price.

In discussing the cartridge with a company representative, it seems that factory fodder is loaded at something close to 50,000 psi, a figure that has been confirmed by at least one lab that I am aware of. At the time of this writing, only one factory load, the 40-grain version, was available for evaluation. This load was closely scrutinized to learn as much as possible about pressure curves, velocities, function, priming, case strength, etc., so that handload data would be safe and

reliable.

Handloading the 5.7x28mm posed a number of challenges and oddities that have never been observed in any other cartridge. For instance, upon retrieving fired cases (from factory loads), it was observed that the case body had a slight reversed taper, as it measured around .007 inch larger in diameter at the shoulder than at the case head, which is simply mind-boggling! Factory loaded ammunition has essentially no taper from the case head to the shoulder or is not more than .001 inch smaller at the shoulder than at the head (a figure that is supported by C.I.P. drawings). Cases were also obtained that had been fired from two other FN Five- Seven USG pistols, and they had a similar reverse taper. Clearly FN is cutting the chambers to this odd dimension, and there is no explanation as to why. Due to the above dimension issues combined with a

bottleneck case that should be full-length resized to achieve proper chambering, case life is not long and signs of case head separation began to appear after just a few reloadings.

Adjusting the sizer die is different than that of conventional cartridges. The sizing die body should first be set in conventional methods. To prevent cases from being crushed while sizing, due to the expander ball and sizer die trying to accomplish their respective jobs at the same time on so short a case, the expander assembly must be adjusted so that it extends as far down as possible. To accomplish this, place a case in the shellholder and raise the ram to its highest point, then screw the decapping assembly down until it bottoms out on the inside (or head) of the case, then turn it up one-half turn and set the locknut.

Powder selection is critical for the 5.7x28mm. Disassembling factory loads (as assembled by Fiocchi USA) revealed that they contained 5.1 grains of ball powder, which was not even close to filling the case. There were

several powders that proved capable of duplicating factory load performance such as Accurate AA-5, AA-7, Ramshot True Blue, Vihtavuori N105, Hodgdon Universal and Alliant Power Pistol. Although performance was certainly acceptable, just like the factory powder, the above propellants failed to fill the case.

Knowing that a slower-burning powder could improve velocities while staying within pressure limits, I proceeded to develop loads using powders that are commonly used in magnum revolver cartridges, which used up most of the case capacity. Pressures were within factory load limits, extreme spreads and accuracy were promising, but due to the blowback design of the FN pistol, impulse energy of the load was too long, and the action would begin to unlock while pressures were still busy driving bullets down the bore. As a result the shoulder was moving forward excessively, leaving a very short neck. Clearly this was the wrong approach

or wrong propellants in an autoloading action of this design, and these loads were discarded. In a closed-breech gun, the cartridge has the potential to deliver significantly greater velocities with slower-burning powders. I was able to get Accurate AA-9 to work properly in conjunction with 45-grain bullets, reaching speeds exceeding 1,750 fps – a load that should be approached with caution to make certain that pressures are low when the action of your gun opens (which may be different than mine).

I was unable to identify or have revealed the primer that the factory ammunition contained. Bullets were pulled and cases reloaded with several of the accompanying loads to compare pressures generated by my handloads versus the factory loads. For all data, a Winchester Small Pistol Magnum primer was used.

Incidentally this primer showed less pressure than factory load primers.

Many of the handloads in the accompanying table were checked for pressures at Western Powders lab, most of which were running between 40,000 and 45,000 psi. It should be noted that my contact reported seeing boat-tail bullets generate 10 to 15 percent greater pressures in the test pressure barrel than the same weight bullet featuring a plain base. There was no explanation as to this oddity, but in the production pistol used herein, a difference in pressure was not generally detectable.

Cases tend to stretch rapidly, so it is suggested to keep them trimmed within specifications, or pressures will likely spike if they become excessively long. It should also be mentioned that a light to medium crimp should be applied to keep bullets in place. A too-heavy crimp will buckle the lightly constructed case at the point of the shoulder, so cases of uniform length will help prevent under or over

crimping and will aid in producing reliable and accurate ammunition.

At the time of this writing, handloading components are largely in a back-order mode, and I was unable to obtain 35-grain bullets for load development. Thus the data includes bullets of 40 and 45 grains only. In 40-grain weight, the Sierra Hornet softpoint and Hornady VMAX each proved excellent, while the Sierra 45-grain Hornet softpoint, Speer softpoint and Hornady Bee hollowpoint also gave excellent overall results. With the exception of the Hornady Bee bullet, none of the above bullets featured a cannelure but was nonetheless crimped in the same manner as factory ammunition.

It is too bad that FNH failed to design the lockup and spring strength of the Five-Seven USG to handle ammunition containing slower-burning powders that offer a longer impulse energy. In other words it left performance on the table so to speak. At any rate, the FN Five-Seven USG functioned flawlessly throughout the load development, and all data in the accompanying table cycled the action. The cartridge is not especially easy to load with perfect results, but armed with the above information, details and data, it can work reliably.

For reloading data that goes with this article, please click the link 5.7x28mm Load Data..