The Springfield Armory 2020 Waypoint provides exceptional accuracy. An RCBS ChargeMaster Link was used to weigh all charges and settle some, such as N-565 and N-568.

I doubt the Super Bowl had more hoopla and media coverage than the

Hornady 7mm Precision Rifle Cartridge (PRC) introduction. Media hype claimed it would end the 7mm Remington Magnum and the 28 Nosler! As I read the data on the 7mm PRC, it made sense. Older cartridges were limited by head height and barrel twist, which, in turn, influenced bullet design and weight. The hype was that the 7mm PRC would outperform all other 7mm cartridges by pushing a ballistically superior long-ogive 175-grain bullet at 3,000 feet per second (fps), extending hunting ranges to 700 yards. Long ogive – heavy for caliber bullets – maintain velocity and energy longer, and more importantly, have less wind drift.

Peterson Cartridge brass held up to repeated usage and provided reliable consistency.

The siren song of the 7mm PRC kept whispering to me. Would a new rifle fix my accuracy problems? I wanted a one-and-done solution. Throwing more money at a new gun didn’t make sense. Finally, I took the plunge. It was the most expensive hunting rifle I had ever bought. Then, Hornady-Gate happened.

After months of glowing reports about the 7mm PRC performance, shooter after shooter reported a considerable drop in factory 7mm PRC ammunition velocity, with most running in the upper 2,700s to low 2,800s fps, while the box data still stated 3,000 fps. I checked the data myself and had the same experience. Finally, Hornady publicly addressed the rumors. The powder source initially specified for the 7mm PRC allegedly dried up due to conflicts overseas. A different powder was substituted to maintain accuracy, which reduced the velocity to roughly 2,800 fps. Although still impressive, it falls short of the factory claim. Overnight, heroes became zeros, and handloaders looked for powders to regain the promised 3,000 fps with exemplary accuracy.

Annealing is important for consistency in neck tension.

In a Hornady podcast, Seth Swerczek told the story of the development of the 7mm PRC and the initial use of 68 grains of Alliant’s Reloder 26, now as rare as unicorn sweat. So, the quest for a comparable powder tops every handloader’s mind. Verified reloading data from well-known ammunition companies for the 7mm PRC is scarce, and most published information falls short of the promised 3,000 fps.

If handloaders strive for ultimate accuracy, they initially do a few critical things. The mantra is to purchase enough powder, bullets and cases to last the barrel’s life. Unfortunately, components are no longer inexpensive or readily available. Magnum rifle primers that I had previously paid less than $30 per thousand now cost me over five times that amount – when I can find them. Many of the powder brands are unavailable. So what is a handloader to do? Use what you can find.

When I first started working up loads, I was using once-fired brass. It was a disappointing exercise as the brass was soft, and the primer pockets became loose after several uses. A local shop had a supply of Peterson Cartridge brass, so I bought two boxes. It was a good investment. They start with tighter primer pockets and form the pocket in multiple steps, which hardens the brass and extends case life. I am at six loadings and counting.

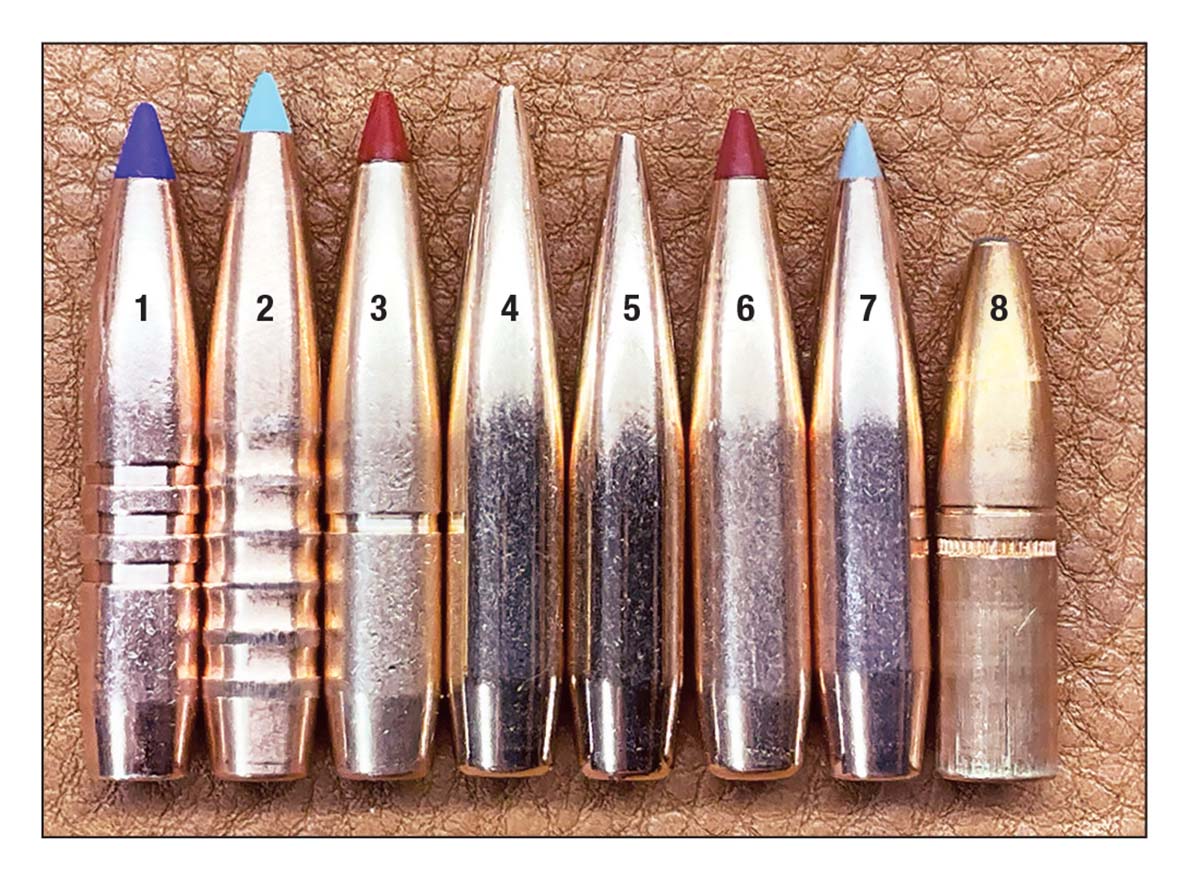

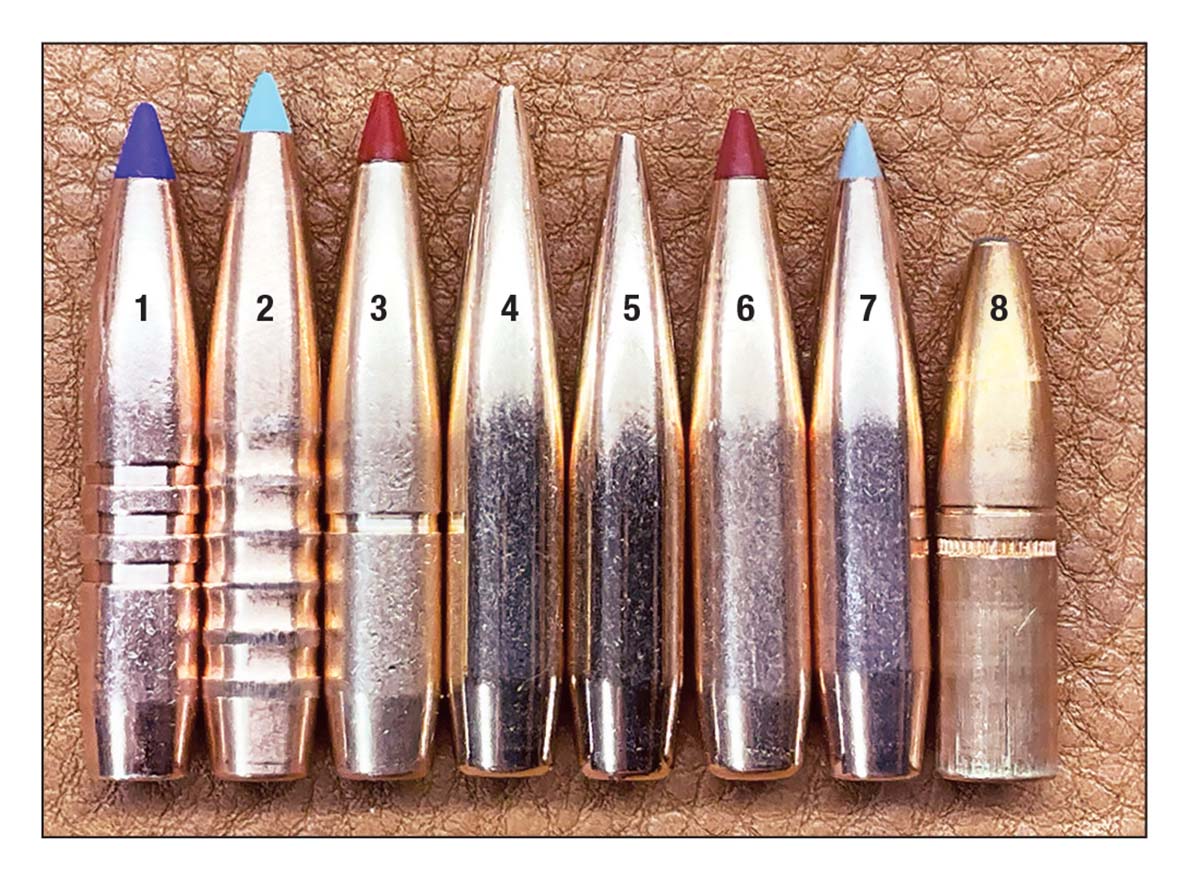

Modern projectiles have a longer secant ogive, which increases their ballistic coefficient: (1) Barnes 168 LRX, (2) Hammer 170 HHT, (3) Hornady 160 CX, (4) Berger 195 Elite Hunter, (5) Berger 175 Elite Hunter, (6) Nosler 175 ABLR and (7) Hornady 175 ELD-X. A 1980s Speer Grand Slam (8) is shown for comparison.

Powder is a different matter. According to my research, the 7mm PRC was developed with Alliant Reloder 26 in mind. I was lucky to find two pounds of it, but that went fast when developing a load, so I started looking for alternatives. The list of available options is short.

H-4831sc – As part of Hodgdon’s Extreme line of powders, H-4831sc is a favorite of mine for my vintage 270 Winchester, and it is easy to find. It is an extruded “stick” powder and is extremely popular for handloaders that hunt big game. Extreme powders are temperature insensitive, making them perfect for hunting game in varying conditions.

Proper cartridge measurement is done base to ogive using a comparator.

With an almost identical burn rate as Reloder 26, I expected H-1000 to perform well in the 7mm PRC. It didn’t disappoint. It worked well with 175- and 195-grain bullets. It is an extruded powder and part of Hodgdon’s Extreme line of powders.

For best accuracy and extended case life, bump the shoulder back .003 inch with a full-length sizing die.

Retumbo was recommended, but it is sometimes hard to find. I had mixed results, but it seemed to do better with heavier bullets. It, too, is an extruded powder and part of Hodgdon’s Extreme line of powders.

StaBALL HD – Winchester’s StaBALL HD is a flattened-ball double-base powder. Unlike most ball powders, it’s formulated to be temperature insensitive. It is slower burning and popular for magnum cartridges, but it gave mixed results.

Grand – Like StaBALL HD, Ramshot Grand is a double-based ball powder. It’s a new powder made in the USA and is found at a lower cost. Don’t let that fool you into thinking it’s subpar. It surprised me over and over.

Always check cases for signs of pressure, such as a heavy bolt lift, blown primers and ejector swipes.

This fine ball powder is extremely slow burning and is normally reserved for big overbore magnums like the 30 Nosler. It’s very hard to find, but I jumped when a guy offered me a sealed bottle at a cut-rate price.

N565 – This Vihtavuori extruded powder was developed for 338 Lapua military applications, but it also works well for smaller bore magnum cartridges. I found the grain size to be larger than Hodgdon extruded powders. In order to get the charge to fit in the case, I used a primer vibratory feeder as a base.

N568 – This Vihtavuori extruded powder is new to the N-500 line and made for magnum cartridges. Like N-565, the grains are larger, and I settled the powder using a vibratory hopper.

The 7mm PRC was designed for long secant ogive bullets, which I strove to use for the testing in Table I.

I have a set sequence for processing the brass and loading the cartridge. It consists of a mixture of steps that I have found achieve my desired results.

The Process

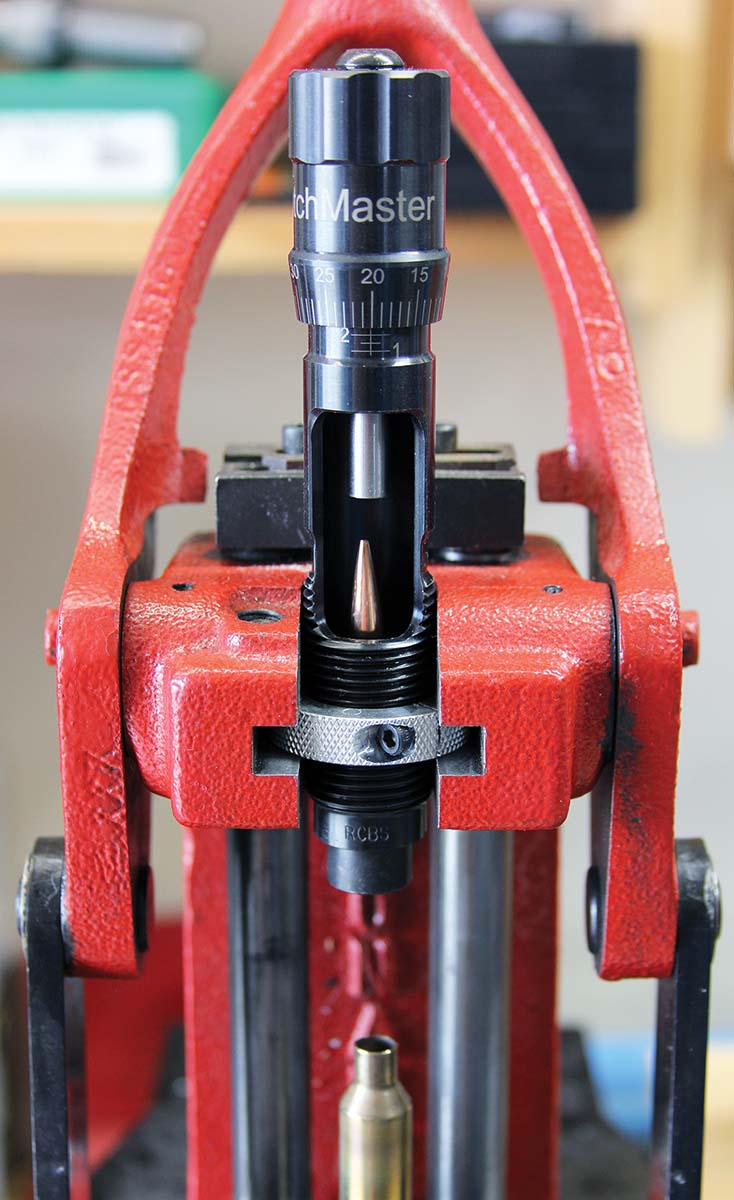

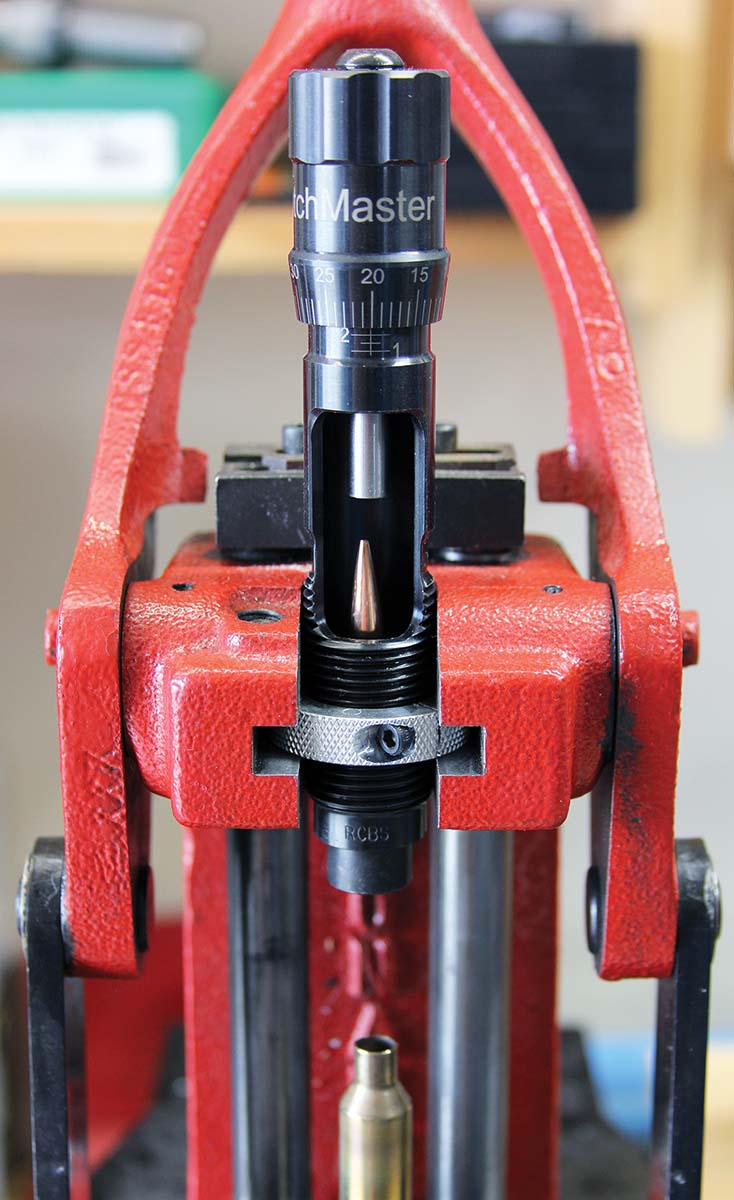

Bullet seating requires concentricity and consistency. The RCBS MatchMaster seater die provides both.

Before reloading, I measure each brand and type of bullet to the lands using a

Hornady Lock-N-Load O.A.L. Gauge set and a Hornady Modified Case. The gauge measures the overall cartridge length with the bullet against the lands. Subtracting the desired jump from the measurement determines the actual bullet seating depth. I like to start 30 thousandths off the lands for lead-core bullets and 50 thousandths off the lands for monolithic bullets. Some competitive shooters claim chasing the lands is a waste of time, while others religiously follow the seating test methods set down in the Berger reloading manual.

After talking to competitive shooters about annealing before reusing a case, I have fallen into the same practice. Each time a case is fired, it work hardens to some degree. With proper annealing, the case mouth is reset to factory hardness. Since consistency is crucial for accuracy, taking the case back to factory hardness is the way to be consistent. I can’t afford one of the new electronic annealing units, but I did find the AGS Brass Case Annealer 3.0 annealer within my budget. I anneal the neck and shoulder after each firing and before sizing. Since starting this, I have not had a case neck split.

Depriming – I use a Lee Universal decapping tool to deprime and expose the primer pocket for cleaning.

Wet Tumbling – Before I send a case through a precision sizing die, I wet tumble with Dawn dish detergent and stainless steel pins, then sort and dry. I used to use dry media in a vibratory hopper but I got tired of the dust and poking the media from the flash holes.

The 7mm PRC has more usable powder capacity when bullets are seated to SAAMI (Sporting Arms and Ammunition Manufacturers’ Institute) specifications.

Using a Hornady Headspace Comparator, I measure the distance from the base to the shoulder on a sample of cases fired in my rifle. These are fire-formed cases, and provided the initial charge used was robust, the fired cases should have expanded enough to reflect the actual size of the chamber. I tend to go with the longest case as my starting measurement.

Sizing – For 7mm PRC and other precision cartridges, I remove the neck-sizing ball from the sizing die and make neck sizing a separate step. Screw the die into the press, down to the shell holder, then back it off a turn or so. Then, carefully screw the die down a little at a time while resizing a case, checking after each move using the headspace comparator. Keep slowly screwing the die in until it bumps the shoulder back three thousands. Verify your results with more cases, then lock the die ring down. I sparingly use lanolin-based sizing lube, cleaning the die with a swab every few instances.

For custom handloads, the actual distance from the case base to the barrel lands is measured for each type of bullet with an OAL tool and modified case.

Case stretch can cause problems with case fit and excessive pressures. As soon as one of the cases reaches the maximum case length of 2.280 inches, all of the cases being used are trimmed back to the minimum case length of 2.270 inches using a Forster case trimmer fitted with a 3-in-1 cutter.

Wet Tumbling – Round Two – A short wet tumble will remove the sizing lube.

Neck sizing – I prefer sizing the necks with a 21st Century Innovations expander mandrel .002 inch smaller than the bullet, making the mandrel .282 inch.

Priming – I primed with a Frankford Arsenal hand primer, as it gives me more sensitivity to loose primer pockets. Throughout the testing, I used Remington 91⁄2M Large Magnum Rifle Primers.

Charging – The RCBS electronic scale measures charges to a tenth of a grain. Some reloading manuals claim a tenth of a grain can change the velocity 10 fps, so I follow the recommended practice of letting the scale warm up and checking its accuracy before each use.

After annealing, the neck is sized with a precision neck mandrel.

I use RCBS’s MatchMaster seating dies. The Match-Master die reminds me of the Vickerman seating die I use for my long-range competition 45-70 loads – except it’s better. The RCBS works almost identically but has a micrometer adjustment to set the seating depth, yet it is short enough to fit under the arm of my Forster Co-Ax Reloading Press.

As stated earlier, I usually seat lead core bullets .030 inch off the lands. Copper bullets seem to like a longer jump, so I often go out to .50 inch off the lands. Some handloaders seat the bullet to match the maximum cartridge overall length (COL). I don’t, because bullet lengths vary significantly from base to tip due to manufacturing tolerances. Even premium bullets can vary .008 inch from bullet to bullet. Out of all the bullets I tested, Hammer bullets were the most precise. More importantly, seating to the maximum COL can cause some bullet styles/brands to jam into the lands as much as .060 inch, increasing chamber pressures.

Reloder 26 provided velocity and accuracy test after test.

The tale of two rifles: I spent over a year gathering data for the 7mm PRC, and I need to warn you that it is folly to assume you will get the exact results I did. I started with a rifle made by a well-known manufacturer and struggled to get groups under two Minute of Angle (MOA). Quite often, the groups were three to five MOA. The velocities I experienced were much lower than those reported by others using the same charge weights.

Hodgdon’s H-4831sc gave exceptional results when the wind wasn’t blowing the shooters around.

After months of struggling, my

Springfield Armory 2020 Waypoint rifle arrived, and it was as if heaven opened up and angels sang. The velocities increased 100 to 200 fps, and sub-MOA groups were commonplace when the wind wasn’t trying to blow me off the shooting bench. I had to go back and start over, as the loads I had made for the first rifle showed increased velocity and signs of pressure, such as blown primers and ejector swipes. The lesson is to start low and work up loads while watching for signs of pressure with any new rifle.

The selection of powders for magnum cartridges can be hard to find. Stock up when you can find it.

After hundreds of rounds, Reloder 26 seems to be the magic sauce for the 7mm PRC, but all the powders and bullets tested performed well with the right combination. All could reach the touted 3,000 fps with a 175-grain bullet. Ramshot Grand was the biggest surprise, as was Vihtavuori N-568. Winchester’s StaBALL HD gave mixed results. Some combinations gave exceptional accuracy while others were all over the target. Hodgdon’s H-4831sc is always a favorite and easily found. In retrospect, the 7mm PRC has tremendous potential, and I suspect new bullets and powders will be developed to take advantage of all it offers. During the testing, I found the Berger 195-grain Elite Hunter combined with H-1000 exciting for future elk, moose, or bear hunting.

In closing, I recommend purchasing a quality rifle that the maker stands behind. The manufacturer of my first rifle said they didn’t provide an accuracy guarantee, but 1.5 MOA was acceptable to them. In today’s market, it’s not! Work overtime, sell plasma, or collect aluminum cans along the highway if needed, but buy a quality rifle and components if you want accuracy. While I was pleased with most of my results, physical limitations prevented me from shooting prone. Had I been able to take my movement out of the testing, the groups would have been even tighter. By the time you read this, I will have gone through surgery and therapy. Wish me luck, and I will do the same for you.

.jpg)

.jpg)

.jpg)