Propellant Profiles

Alliant Red Dot

column By: R.H. Vandenburg, Jr. | June, 19

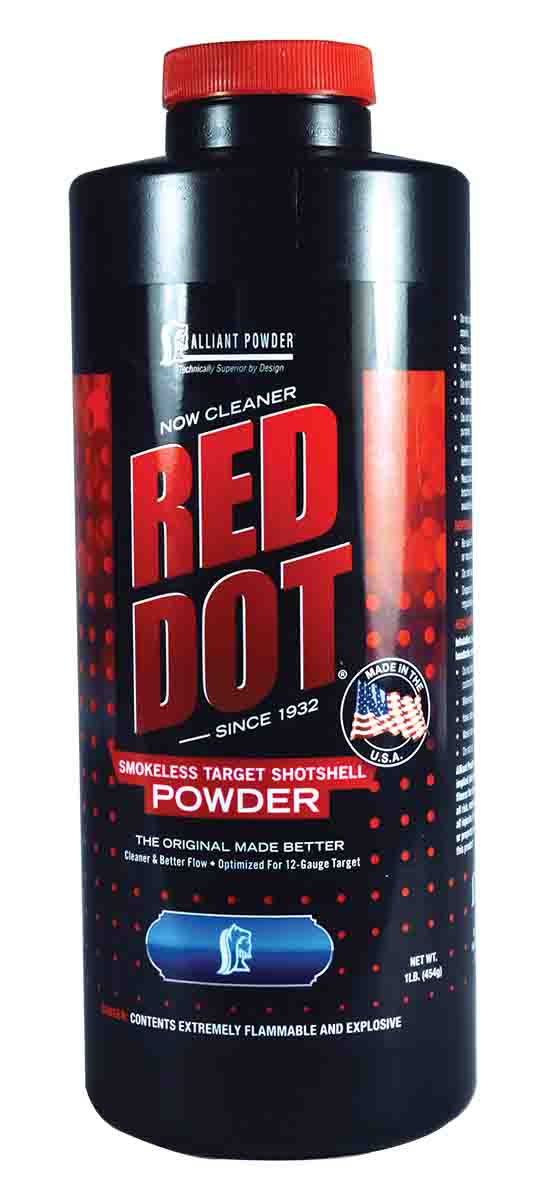

By now, most of us are likely aware that the Alliant Powder Company is in the process of upgrading its double-base, flake powder line. In 2018, the company announced improved versions of its Red Dot and Green Dot powders. In 2019, Herco was added to the list. In each case, the new releases are weight-for-weight and volume-for-volume replacements for the older releases, meaning we can use the same powder bushings and powder weights we’ve always used, and any published data will work with either release.

Being most interested in Red Dot, having used it for years in 12-gauge target loads and in myriad handgun cartridges, I requested samples.

Red Dot has a most interesting history. First introduced in 1932 by Hercules, it was an immediate success as a shotshell powder, especially in 12-gauge target loads, but was frequently used in light 16-gauge and 20-

When Alliant Techsystems of Minneapolis, Minnesota, purchased the smokeless powder division from Hercules, it moved production to the Radford Arsenal in southwest Virginia. By 1999, the move was complete, with a new processing line creating a forth iteration. This one promised and produced a cleaner-burning, more consistent product line and was highly publicized with new packaging and labels. Now, 20 years on, prompted by improved technology and increased competition, handloaders have a fifth version that, so far, includes Red Dot, Green Dot and Herco. Improved metering, tighter controls for shot-to-shot consistency and even a cleaner burn are promised.

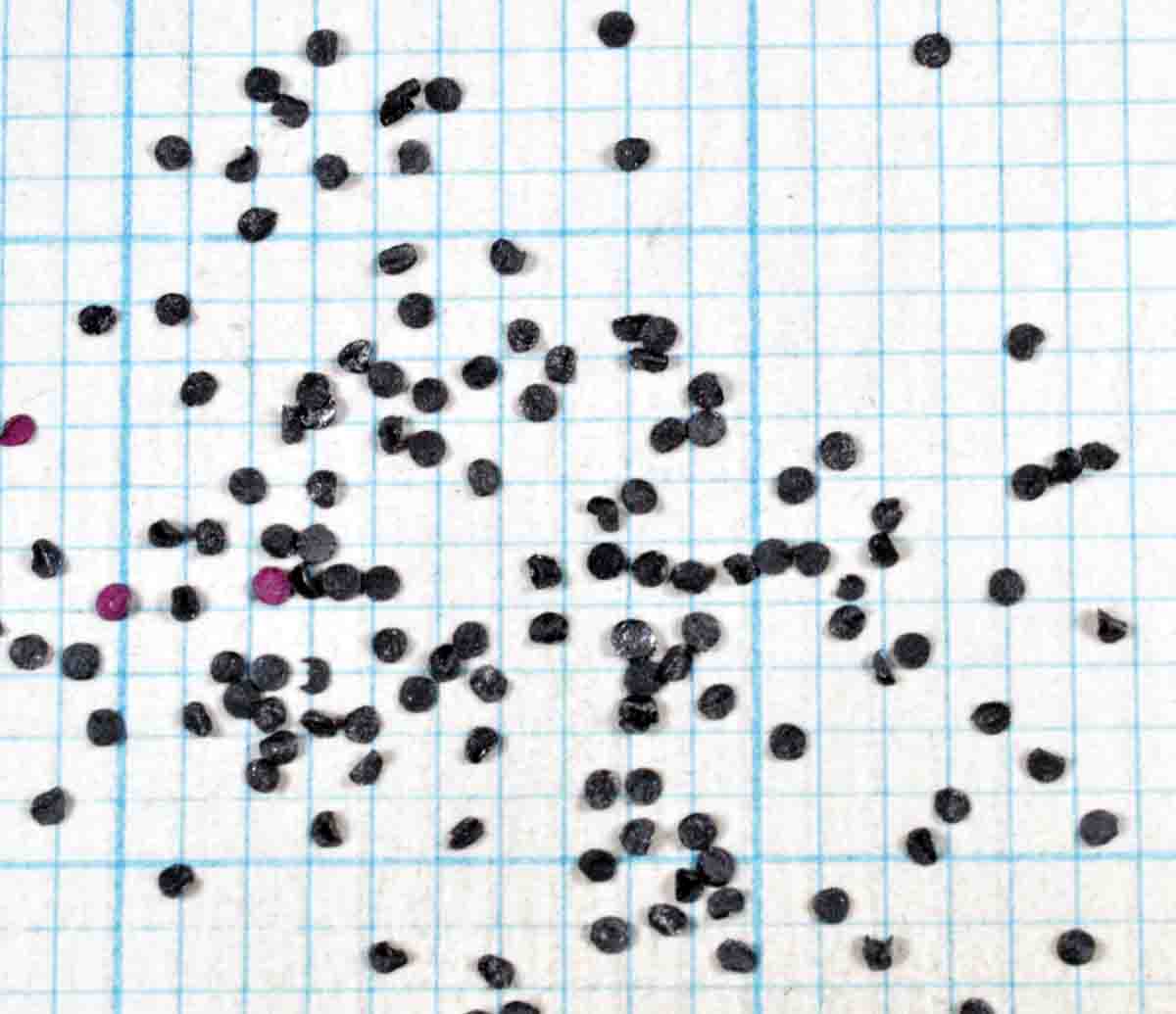

Red Dot continues to be an extruded, double-base, flake powder with a diameter of .058 inch and a thickness of roughly .0045 inch. Its nitroglycerin content remains 20 percent. Bulk density, in the .500 range, remains quite low. The familiar red-dyed flakes remain, and the integrity of the name is intact.

Having some of the previous iteration on hand, I set out to compare it to this latest release. Visually, the new powder appears lighter in color – a byproduct of an improved manufacturing process, I’m told. I first set a powder measure to throw a randomly picked charge that might be used in a light, 12-gauge, 11⁄8-ounce target load. Throwing 10 charges of each powder, the older lot averaged 16.82 grains; the new lot, 17.18. Given the sample size and the fact that I was working with only one can from each release, I considered the difference insignificant. Extreme spreads were identical at .2 grain.

Next, I selected a typical 12-gauge target load from the Lyman Shotshell Reloading Handbook, 5th Edition and loaded five shells with each powder using Federal Gold Medal hulls; Winchester 209 primers; Federal 12S3 wads; 11⁄8 ounces of small lead shot; 19.5 grains of Red Dot for a velocity of 1,185 fps and a pressure of 10,500 psi.

Firing each shell over the screens of an Oehler Model 35P chronograph 6 feet from the muzzle, the older lot registered 1,186 fps; the new lot recorded 1,217 fps. The old lot provided a velocity spread of 27 fps, and the new lot had an extreme spread of 23 fps. Once again, given the size of the sample, there is no statistical difference.

Turning to handgun cartridges, I went back to a review on these pages of the previous iteration in 2008. Where possible, the same load data and components were used. I also added a couple of cartridges to the mix, the .44 Russian and the .44-40 Winchester. As with the shotshell test, I recorded slightly higher velocities this time around but, as before, nothing of a statistically significant nature. As promised, this

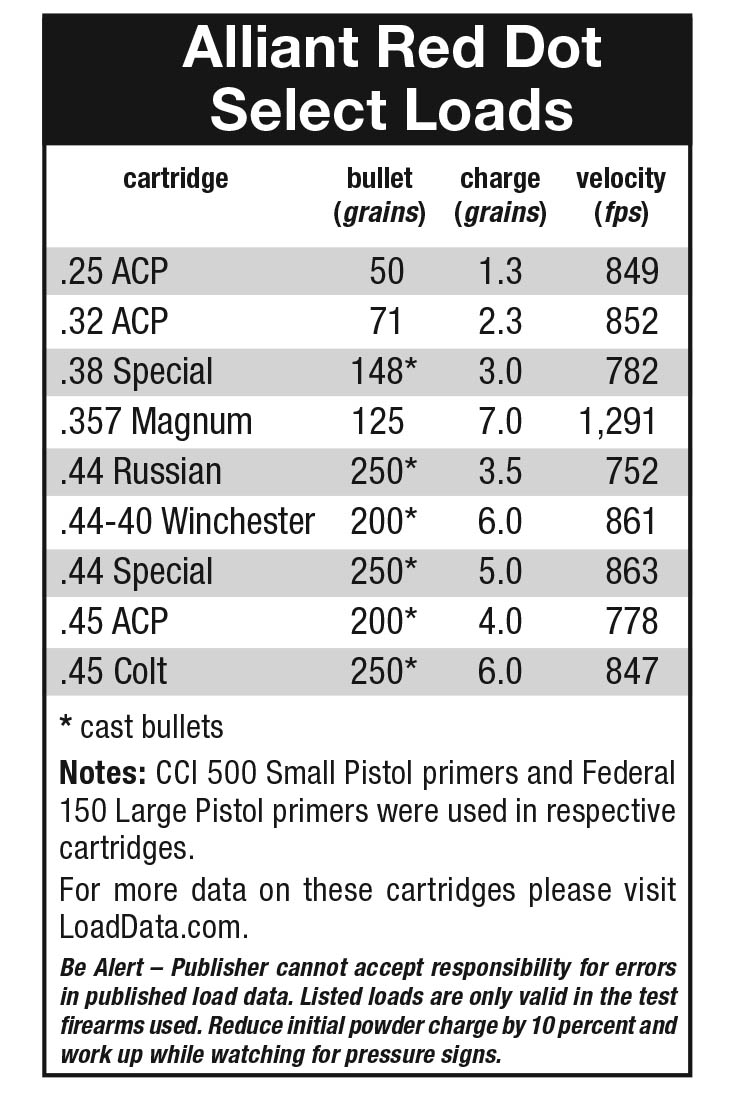

I began with the .25 ACP. Most of the faster-burning powders work well here as target-quality accuracy is not required, or possible, given the nature of the guns chambered for this cartridge. Red Dot has to be included in the list of those that do. The same is true of the .32 ACP. My pet Walther PP performed well with this powder and a Sierra bullet. Velocity was only slightly increased over the previous powder lot, and accuracy at about 15 meters remained quite good.

The .38 Special was shot with a 148-grain cast wadcutter. This time I increased the powder charge from 2.3 grains to 3.0 with an accompanying increase in velocity. I like the results, though, with good groups and small extreme velocity spreads. In the .357 Magnum, a Sierra 125-grain jacketed hollowpoint bullet was used. Red Dot is probably not the ideal powder for this combination, but velocity was fine as were the extreme spread and accuracy from my Ruger Security Six.

The .44 Russian was added this time, using a Smith & Wesson Model No. 3 replica from Cimarron Arms. A 250-grain cast bullet was as close as I could come to the 246-grain bullet of the original cartridge. The powder performed well, as expected, and groups were quite good. The .44-40 Winchester cartridge was also new to these tests. I’ve been shooting the cartridge a lot over the past couple of years comparing a variety of powders. Some performed better than others. From these tests, I’m going to have to include Red Dot in the list of those that do perform well. Red Dot and the .44 Special have served me well over many years, and this latest version only adds to the memories.

Most target shooters probably don’t use Red Dot in their .45 ACP guns but maybe they should. It’s cleaner burning than the more traditional Bullseye and, in my tests, was just as accurate. In the .45 Colt, Red Dot has developed quite a following over the years with many knowledgeable shooters preferring this powder over all others for duplicating factory loads. You can count me among the fans.

While I would have been shocked had the tests turned out any other way, I’m happy to proclaim this latest iteration of Red Dot an improvement on that which already has been an 87-year success story.