Propellant Profiles

Alliant Reloder 50

column By: Randy Bimson | June, 24

In this issue of Handloader, I am going to take a look at one of the more specialized propellant powders in the Alliant lineup, Reloder 50, also known as RL-50. This powder has limited applications and from Alliant’s current corporate position, as the product name implies, RL-50 is marketed as a 50 BMG specific propellant. I am well aware that some readers are using RL-50 to reload cartridges such as the 338 Lapua Magnum, 408 and 416 CheyTac, 28 and 30 Sherman Magnum, but given the lack of published pressure test data from accredited sources, I am going with Alliant’s current position and focusing on the 50 BMG application.

Let’s delve right into the physical characteristics of RL-50 and then branch out into a more general discussion on the attributes and limitations of this interesting propellant.

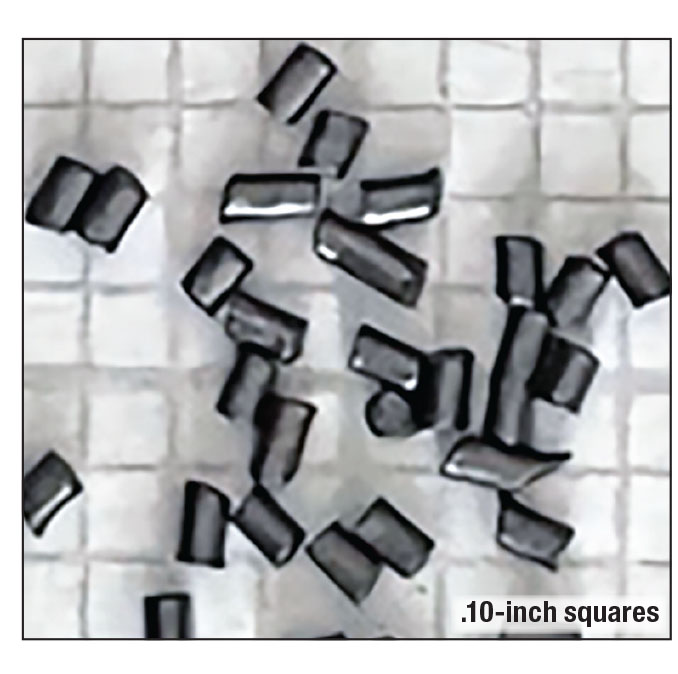

RL-50 is a double-base extruded powder – a “chunky” powder indeed. The granules have a grayish-black color and a short and fat physical appearance. The granules are a nominal .075 inch in length and are .051 inch in diameter. The web dimension of the RL-50 granules is not easily measured, and the exact specification is considered again, a proprietary design detail of the manufacturer. The exact nitroglycerine content is considered proprietary information by the manufacturer as well but it is considered a low nitroglycerine content for a double-base powder.

RL-50 is one of the Reloder series of propellants that Alliant contracts with its European-based energetics partner, Nitrochemie Group, in Wimmis, Switzerland, to manufacture to Alliant specifications.

How well does RL-50 meter when using a powder measure? For test purposes and loading the ammunition used to qualify this column, I used my Custom Products Micro Measure. This is the same measure I use to dispense exacting charges for most of the rifle cartridges I load for. The heaviest charge of RL-50 the Micro Measure will throw is a nominal 121 grains. Since Alliant’s load data for the 50 BMG calls for charges of 230 to 250 grains of RL-50, by weight I threw 20 individual charges weighing an average of 119.6 grains. I combined every two charges as one single charge, so the end result was 10 charges with a combined total average charge weight of 239.2 grains. The extreme spread of the 20 individual charges thrown was .6 grains while the standard deviation was .23. The largest diameter drop tube I have for the Micro Measure is for .30-caliber cases. I did have a few instances of bridging of the powder charge when setting up for the testing and loading. I then slowed the speed of the Micro Measure handle to allow more time for the powder to transition from the metering chamber into and down the drop tube. There has been no bridging of the powder charge since then. I think a drop tube with a larger internal diameter than the .30-caliber tube would cure that minor inconvenience. It would be interesting to have had Hornady’s 50 BMG powder measure, which will throw a nominal 265-grain charge per handle stroke, on hand for comparison. Either way, I think an extreme spread of .6 grains on charges as large as I was throwing speaks highly of RL-50 and the Micro Measure.

Load testing was limited to three-shot groups for two reasons. One was the cost of components. Bullets like the Barnes, Cutting Edge, Hornady and Lapua cost $2.50 to $3.50 per bullet. Primers, CCI No. 35 for example, have an average price that nets out at $1 per primer. A pound of RL-50 will load a measly 29 cartridges at 239 grains per cartridge. The second reason is that after three shots, the barrel on my 50 BMG test rifle was getting hot!

I was able to borrow a 50 BMG chambered rifle that I built back in the 1990s for an industry friend who prefers to be unnamed. The rifle is built around Rock McMillan’s single-shot version of the predecessor action to today’s TAC-50, nestled in a McMillan composite stock. The 30-inch barrel was crafted by noted 50 BMG benchrest barrel maker, Ken Johnson of K&P Gun Company & Rifle Barrels, in Rapid City, South Dakota. The rifle is fitted with one of Ken’s ultra-effective muzzle brakes, what I refer to as a “105 howitzer” clamshell-type brake. Optics have recently been updated to the Burris XTR III 5.5-30x 56mm riflescope. As set up, this rifle weighs just under 30 pounds.

All the ammunition used was loaded on a heavy-duty RCBS Big Max press, a carryover from our shop up in the Canada days, along with the unusual 13⁄8 inch x 12 threads per inch 50 BMG dies it requires. Primers are seated using the Big Max press 50 BMG ram-primer assembly. All powder charges were dispensed using the Custom Products Micro Measure. The Micro Measure powder charge setting was verified using a Redding Model No. 2 scale. A Lyman Brass Smith powder trickle was used to bring charges up to the desired final weight.

People shudder at the thought of shooting a shoulder-fired rifle chambered for the big 50 BMG off the bench. Well, I can tell you from personal experience, this rifle is a blast to shoot! K&P’s clamshell muzzle break tames the recoil down to little more than a 22-250 varmint rifle. Mind you it will, literally, clear your shooting bench of everything that is not weighted down along with the hat on your head! On top of that, it gives the distinct feeling that it is momentarily sucking all the air away from around you. The muzzle blast is significant with such a large brake.

When I was building 50 BMG rifles commercially in Canada, the biggest issue was ammunition. Our two boys were 11 and 13 then, and they loved nothing more than shooting a 50 BMG setup, which was pretty much like the one described here. When we took a completed rifle out to test fire, I had to limit the amount of ammunition the boys could shoot.

RL-50 has proven to be an outstanding powder for its intended application, the 50 BMG cartridge. In my experience, it meters excellently from the given powder measure. It burns very cleanly, leaving little residue in the barrel. Given good loading techniques, RL-50 is capable of delivering velocities that show very low extreme spreads and standard deviation. Add a quality bullet on top of that and the accuracy will be excellent.

RL 50 is packaged in 1- and 8-pound canisters. If you are serious about shooting a fun 50 BMG-chambered rifle like the one described above, buy the 8-pound canister, as 240 rounds will not seem like a lot of ammunition after you squeeze off that first shot.

.jpg)