Propellant Profiles

Evolution of Propellants and Internal Ballistics (Part Three: Conclusion)

column By: Rob Behr | December, 25

The Ballistic Pendulum

Up until the mid-18th century, a time when both small arms and cannons were already well-established weapons, there was no way to accurately measure chamber pressure or the starting velocity of a projectile. Firearms were simply tested with “Proof Loads” that exceeded the standard charge of powder and then inspected for damage. Velocities could be crudely inferred by the time it took a projectile to hit a distant target, but this only provided a rough estimate of velocity at the time of impact rather than at the muzzle. A clever device created by an English mathematician solved that problem and introduced the first significant scientific tool of internal ballistics.

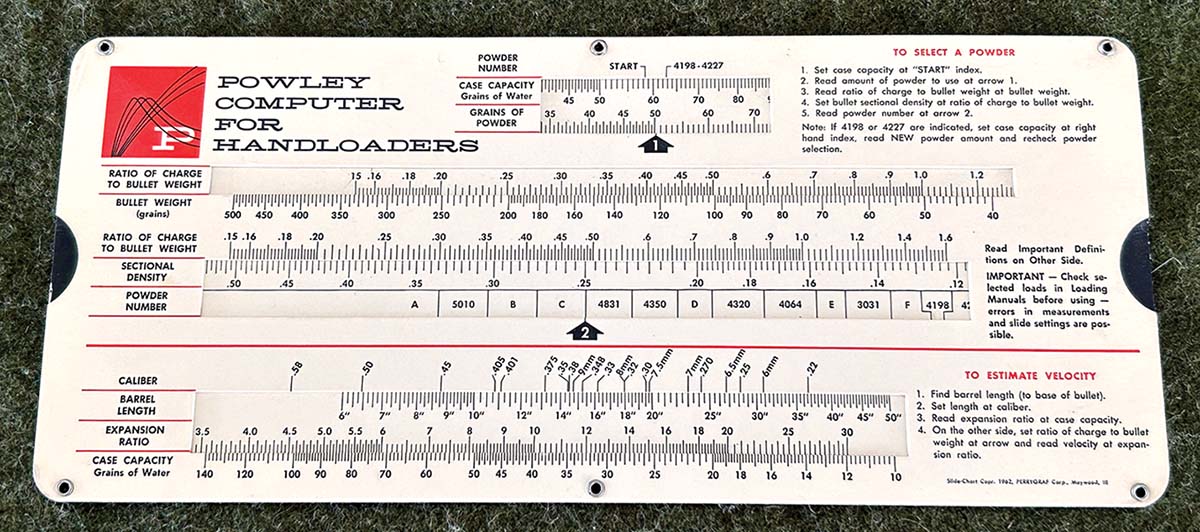

The Ballistic Pendulum, invented by Benjamin Robins, was based on the physics of momentum. The pendulum was made from iron and used a target face made from wood that was thick enough to catch and hold a one-ounce musket ball. A ribbon was attached to the pendulum and a fixed, loosely clamped guide. When shot, the pendulum’s movement, its chord, could be measured by the length of ribbon pulled through the guide. After that, finding the bullet’s velocity was a straightforward mathematical computation. Robins explained his methodology in his book, New Principles of Gunnery. Published in 1742, it is still considered a seminal text on ballistics.

Grobert’s Chronograph

Colonel Grobert, an officer in the French Army, is credited with creating one of the first successful chronographs in 1804. His machine consisted of two paper disks spaced approximately 13 feet apart. These disks were spun on a rapidly moving axle. A bullet fired along the axis of rotation created holes in the disks that could be measured for angular displacement over the known distance between the two targets. The first target represented the start value. The second target disk, because it was in motion at a constant velocity, reflected the elapsed time by showing how far the target had rotated over the bullet’s 13-foot flight.

Copper Units of Pressure (CUP) and Lead Units of Pressure (LUP)

In the mid-1800s, Alfred Nobel proposed the use of a crusher system to measure chamber pressures in firearms. This system required a hole to be cut into a chamber or barrel of a test firearm. A piston was placed into the hole and a small cylinder of either lead or copper (depending on the pressures to be measured) was placed on top. A fixed anvil was then installed to cap the system. Through careful measurement and by consultation with charted data, a pressure baseline could be established. This system was the world standard up until its dominance was challenged by electronic transducers in the 1960s. Although mostly antiquated by the more accurate electronic pressure systems, data using CUP is still in common use.

There are several drawbacks to the copper crusher system. Because the billet of copper is crushed over a longer time frame than it takes for the chamber to reach peak pressure, CUP tends to underreport maximum achieved pressures.

Because Copper Units of Pressure is a system based only on itself, CUP does not accurately translate into other standard pressure units like pounds per square inch (psi). Denton Bramwell is credited with a formula that approximates a conversion from CUP to a Piezo transducer result, but only on a pressure scale between 28,000 and 54,000 CUP. It does, at least, offer an insight into pressure comparisons between the two systems Bramwell’s formula is: Peizo Result = 1.52 x Crusher – 18,000

Piezoelectric Transducers

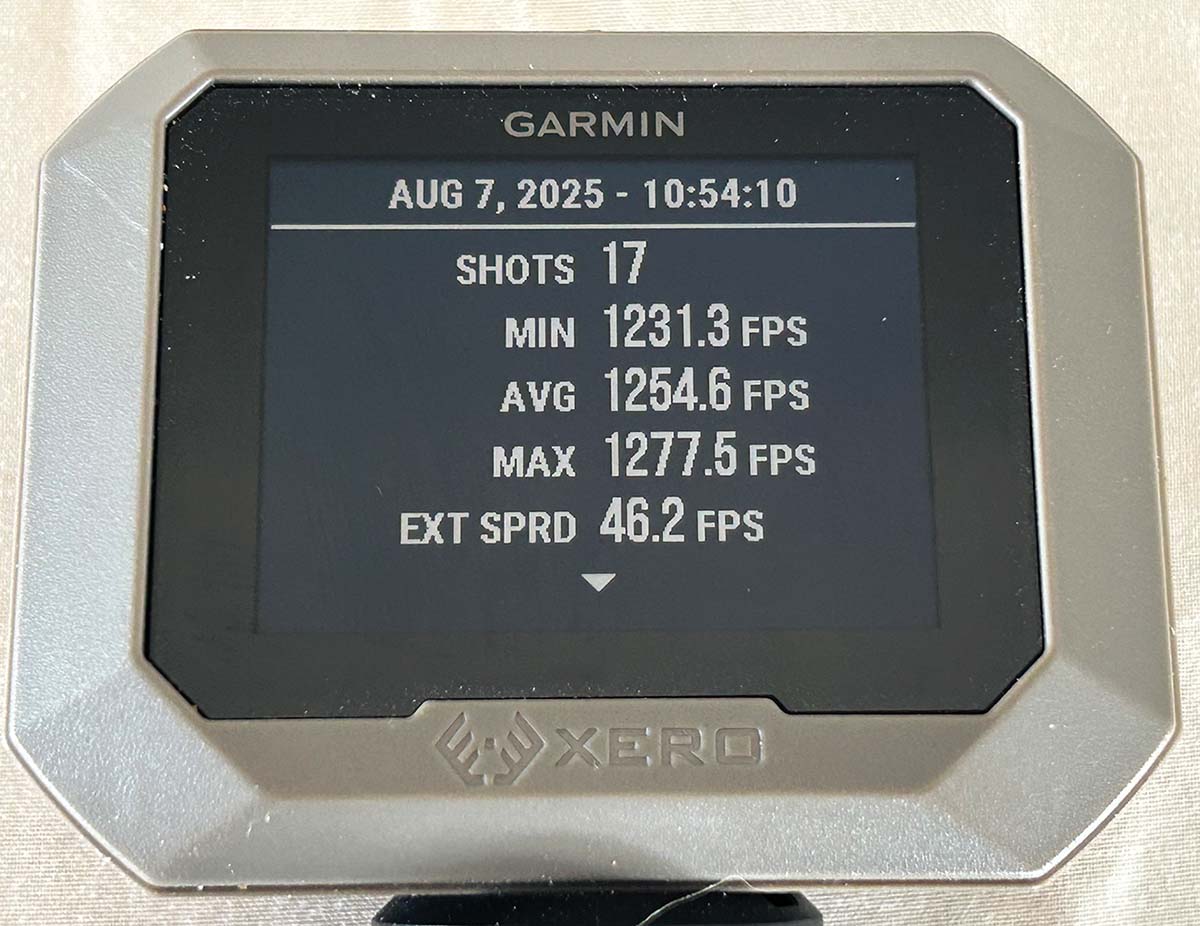

The American-based Sporting Arms & Ammunition Manufacturers’ Institute (SAAMI) and the Brussels-based Commission Internationale Permanente (CIP), which is the regulatory board for small arms in Europe, are the primary drivers of small arms and ammunition testing in the Western world. Even though the two organizations use different methodologies, both now use piezoelectric transducers as the preferred method for firearms-related testing.

SAAMI methodology calls for the use of pressure barrels cut to accept a transducer designed to match the chamber diameter of a specific cartridge. Called the conformal system, a transducer’s diaphragm is placed in contact with the test cartridge, essentially becoming part of the chamber wall. Upon being fired, the case expands and impacts the transducer. This creates an electrical impulse that can be directly translated into psi. The transducer is able to track pressure changes as the bullet moves down the barrel, offering far deeper insights than those of the CUP system. If there is a drawback, it lies in the technical task of measuring case offset, which accounts for the amount of pressure that is absorbed by the cartridge wall before it begins to expand. From personal experience, I know this to be a laborious process.

The CIP system is simpler, but somewhat alarming for the first-time technician. Using CIP methodology, a hole is drilled into the live cartridge at a point precisely 25 millimeters from its base. In cartridges like the 9x19 Parabellum, which is too short for the standard guideline, the hole is cut at 12.5 millimeters from the base. The cartridge is then carefully located to expose the drilled portion of the case against a piezo transducer. When fired, the driving gases impinge directly on the transducer, providing pressure in bar or Megapascal (MPa) I will say, again from personal experience, that the first time you drill into a live cartridge it seems like a poor life decision.