Inline Fabrication

Forster Products makes some excellent products for the precision-minded handloader from the Co-Ax Reloading Press to primer seaters and other various tools. Over the past month, they have been extensively used on this bench assembling consistent handloads.

As many have likely noticed over the last few “Reloaders Press” articles, there have been several tables with a larger-than-normal number of shots for a group. Either 20 or 25 shots along with a mean radius measurement. Over the past year or so, much testing has been conducted with these larger sample sizes in an effort to narrow down variables and increase the overall consistency and performance of handloaded ammunition. Whether that is done by reducing the mean radius, group size, or velocity variation, much experimenting and testing has been conducted and is still underway.

The test rifle for this article and the loads was a GA Precision Pinnacle Production Rifle (PPR) with their Gladius II Short action and a 26-inch heavy contour barrel and 4 port muzzle brake.

In this article, the focus is on several products we have recently started testing. Although the products themselves are not new, the testing we at

Handloader magazine have conducted with them is. Over the past month, we’ve conducted extensive evaluations of the

Forster Co-Ax Reloading Press, the

Co-Ax Primer Seater, the

Original Case Trimmer, and various other precision tools designed to improve ammunition consistency. One especially useful tool we ordered is the

Forster Neck Tension Gauge, which is invaluable for verifying consistent case-neck tension and diameter, as well as ensuring there’s no brass ring or “donut” inside the case neck after reforming or resizing cases. These tools are used in the hope of reducing variables and producing more consistent ammunition.

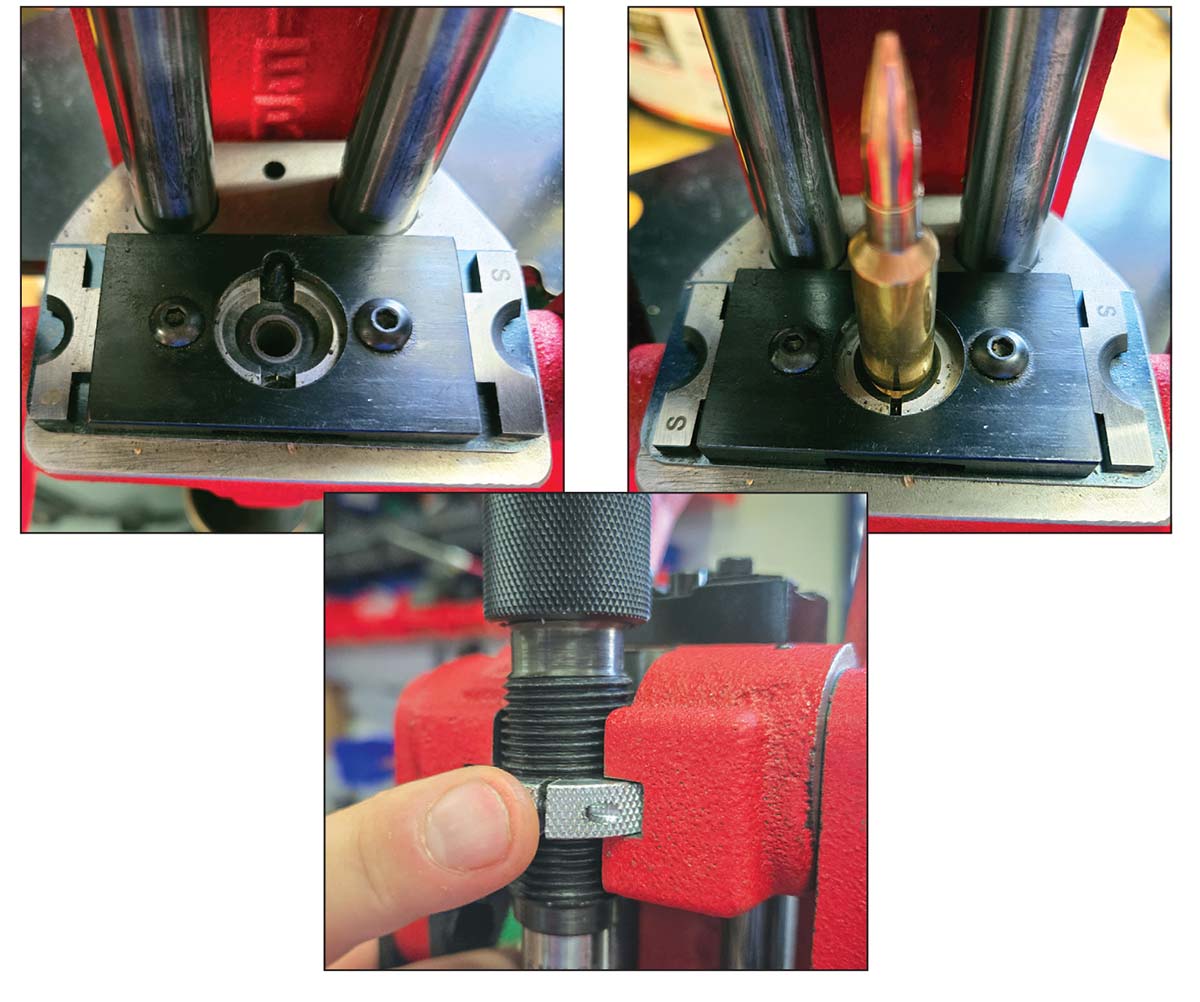

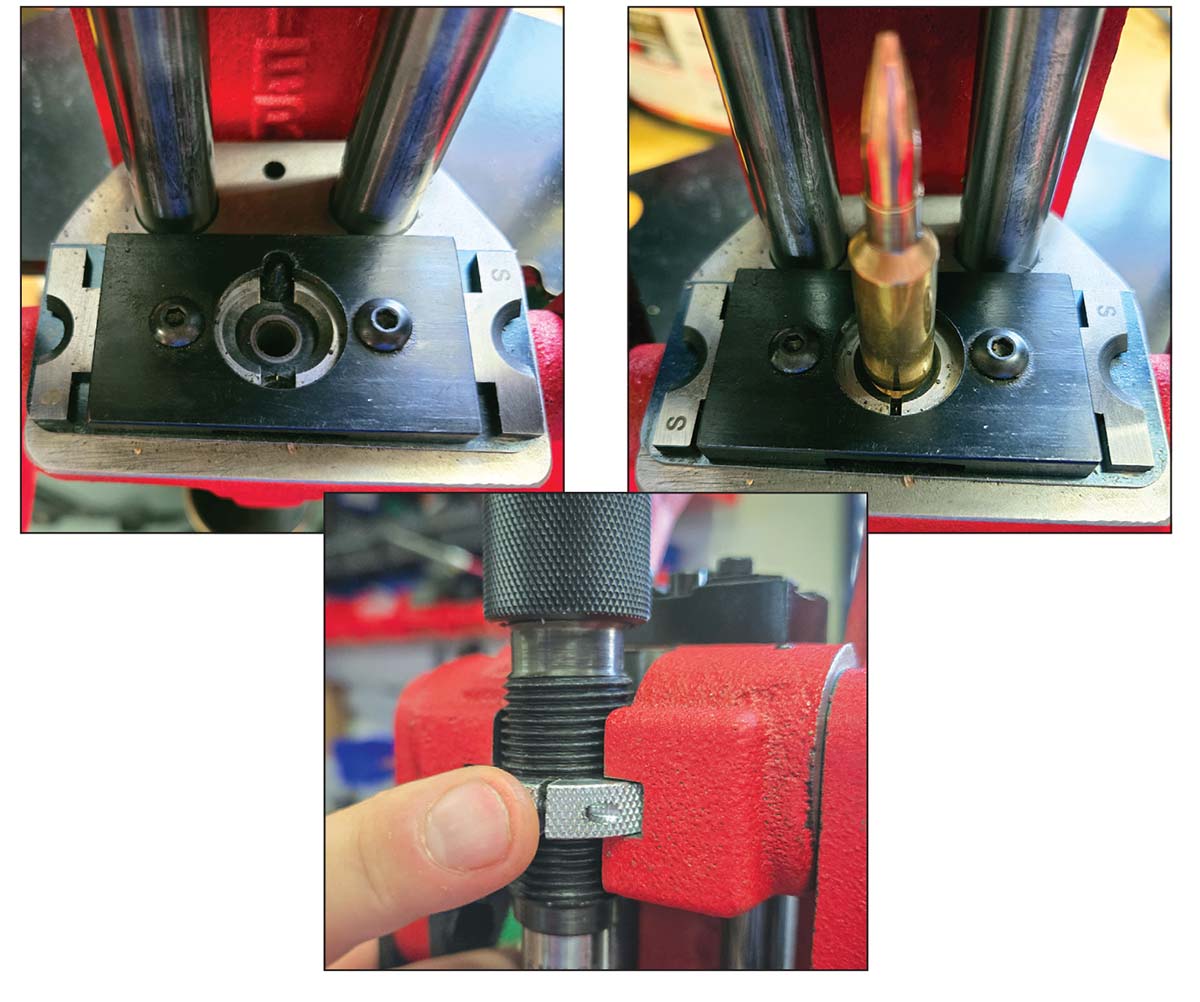

The Forster Co-Ax Press does not require shell holders thanks to the “S” jaws that close as the press lever is pulled to hold the cartridge during press operations. Another nice feature that makes the press easy to use and quick to set up is the fact that the dies slide in. Once a die is set to the press it’s as easy as popping them in and out to swap dies.

A unique opportunity arose to test the same rifle featured on our cover and in Patrick Meitin’s accompanying "6mm GT Target Loads" feature article. For more details on the rifle, its cartridge history and additional load data, please refer to that article. Having two writers shoot and handload for the same firearm provides perspective and allows us to verify that the information we present is reliable, honest and repeatable for our readers. To my knowledge, no other publication consistently approaches testing with the level of thoroughness that we do. We often share load development results on

Handloader TV using rifles our writers have previously reviewed. This might sound like a shameless plug – and, frankly, it is. We take great pride in the depth and dedication we put into load development and in providing the best possible information to our readers. With that in mind, let’s dive into the Forster Co-Ax Reloading Press.

The Co-Ax Press was originally developed and manufactured by Bonanza in the 1960s. Forster purchased the rights to the press and the Bonanza company in the mid 1980s. It is a cast iron press that provides exceptionally good leverage thanks to its unique linkage design. It has an excellent reputation for ease of use, durability and producing consistent ammunition. My experience with the press was no exception. My favorite feature of this press is that, thanks to the integrated adjustable sliding “S” jaws that close to grip the case while operating the press, there is essentially no need to change shell holders. If you like to de-prime your cases before cleaning or resizing, this greatly speeds up the de-priming process and saves you from digging through your tool bin to find the correct shell holder. Simply place the case in the jaws and go!

Both Creed and SW-4350 powders from Shooters World performed well with some excellent groups with 105-grain Berger BT Target bullets and 110-grain Hornady A-Tip bullets.

The first thing I did when I received the press was spin a Forster Lock Ring onto my FW Arms universal decapping die and install it on the press. This was as simple as pushing the die into the slot on the press and setting the die down 1⁄4 inch from the “S” jaws. I then proceeded to decap a two-gallon bucket filled with assorted cases of various sizes, from 500 Smith & Wesson Magnum down to 221 Fireball – all without ever having to change a shell holder. During that process, not a single spent primer fell to the floor; they were all captured in a primer catch cup, which is more than I can say for most reloading presses on the market today. Another nice feature is once your die is set, all you have to do is set the lock ring, and the die simply slides in and out of the press. No more screwing the die down through several inches of threads. This makes die swaps quick and easy.

The Co-Ax can reload some large cartridges; the clearance from the bottom of the “S” jaws to where the die sits is about 4.2 inches, so it can handle many of the popular big magnum cartridges like the 338 Lapua Magnum. However, they do make the Co-Ax XL press for larger cartridges such as the Cheytac line and the big 50 BMG. It also provides more space for seating bullets beyond the Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI) cartridge overall loaded length with magnum cartridges like the 338 Laupa. One of the most interesting features of the Co-Ax presses is that both the die and case have some engineered “float” in their design. This allows the cartridge case and die to move slightly to align with each other. The idea is that if everything lines up properly, then the overall concentricity during sizing and bullet seating should improve.

The 6mm GT Case was designed with Varget powder in mind and it provided some excellent results with the 109-grain Berger Long Range Hybrid Target bullet. This is also directly comparable to a load that Patrick Meitin used in this issue in his 6mm GT feature. H-4350 is another favorite in the 6mm GT, and as a whole, slightly outperformed Varget in this test.

In order to present some hard data to the reader for this article I decided to use Patrick’s test rifle – a GA Precision Pinnacle Production Rifle (PRR) which uses their Gladius II short action chambered in 6mm GT. I felt this would make for an excellent test platform to test this new equipment and also compare and contrast results and notes from another excellent shooter.

Using the Forster Co-Ax combined with the Forster Bushing Full Length Sizing Die and the Ultra Micrometer Seater Die, I assembled loads using Lapua 6mm GT cases. Everything was carefully checked, and cases were trimmed to a uniform length. Neck tension was verified with the Forster Neck Tension Gauge. I seated Federal Gold Medal Match Small Rifle primers using the Forster Co-Ax Primer Seater. When it came to seating bullets, the Ultra Micrometer Seater Die did a great job, and the average runout for 150 seated bullets measured .002 inch of total indicator runout just forward of the case neck.

Using Winchester StaBALL Match powder and a 95-grain Berger VLD Hunting bullet this was the smallest group recorded, measuring a mere .34 inch.

The loads were tested in the rifle under less-than-ideal hot, and somewhat windy, conditions but nevertheless, the results were very good. Overall, I was pleased. The extra attention to detail and having the tools to check for uniformity, size cases and seat bullets consistently and concentrically seem to have contributed to the overall results shown in the load table. Looking at the table, we can see that the rifle consistently shot under .75 MOA at 100 yards. There was no cherry-picking of loads to assemble this table; the overall consistency of the rifle was extremely good. Despite testing 20 different loads through this rifle, not a single load broke 1 MOA.

Looking at some numbers, we see that the average group size is .546 inches across the 29 different loads tested. The standard deviation was .168, with a 95 percent confidence interval range of .482 to .609. These results are extremely impressive, especially considering this is across 29 different loads. I have no doubt that this rifle can indeed hold 1⁄2 MOA with a good load, which is the accuracy guarantee of this rifle. With good loading equipment, a little patience and better conditions, I would even say that these results could be better than consistently 1⁄2 MOA. This is a phrase I often hear, but it is seldom backed up with a target showing a full day’s worth of holes all clustered into a tiny sub-half-minute group. It is extremely impressive what a difference good tools and equipment can make when it comes to assembling ammunition.

.jpg)

.jpg)