Wildcat Cartridges

22 Hornet Improved

column By: Layne Simpson | February, 24

I doubt if any cartridge has been “improved” by more people than the mild-mannered little 22 Hornet. From a technical point of view, improved versions of the 22 Hornet existed prior to the introduction of the cartridge by Winchester in 1932. To understand how that could have happened, we will have to turn back the calendar to the 1920s when various gunsmiths began searching for ways to improve the performance of an old black-powder cartridge called the 22 WCF or 22-15-45 Winchester when it was introduced in 1890. One of those gunsmiths was Adolph Niedner whose 1920s 25-caliber wildcat on the 30-06 Springfield case went on to be domesticated by Remington in 1969 as the 25-06 Remington.

The 22 WCF stayed in production until 1935 and when Winchester decided to introduce a “new” varmint cartridge in 1930. The headstamp on 22 WCF cases was changed to read “22 Hornet.” The 22 Hornet case was eventually beefed up a bit to strengthen it and due to the reduction in capacity, some of the early load data is excessive for today’s cases. The first rifle offered by Winchester in 22 Hornet was the Model 54 and when it was improved and reintroduced in 1937 as the Model 70, the 22 Hornet was among its options as well.

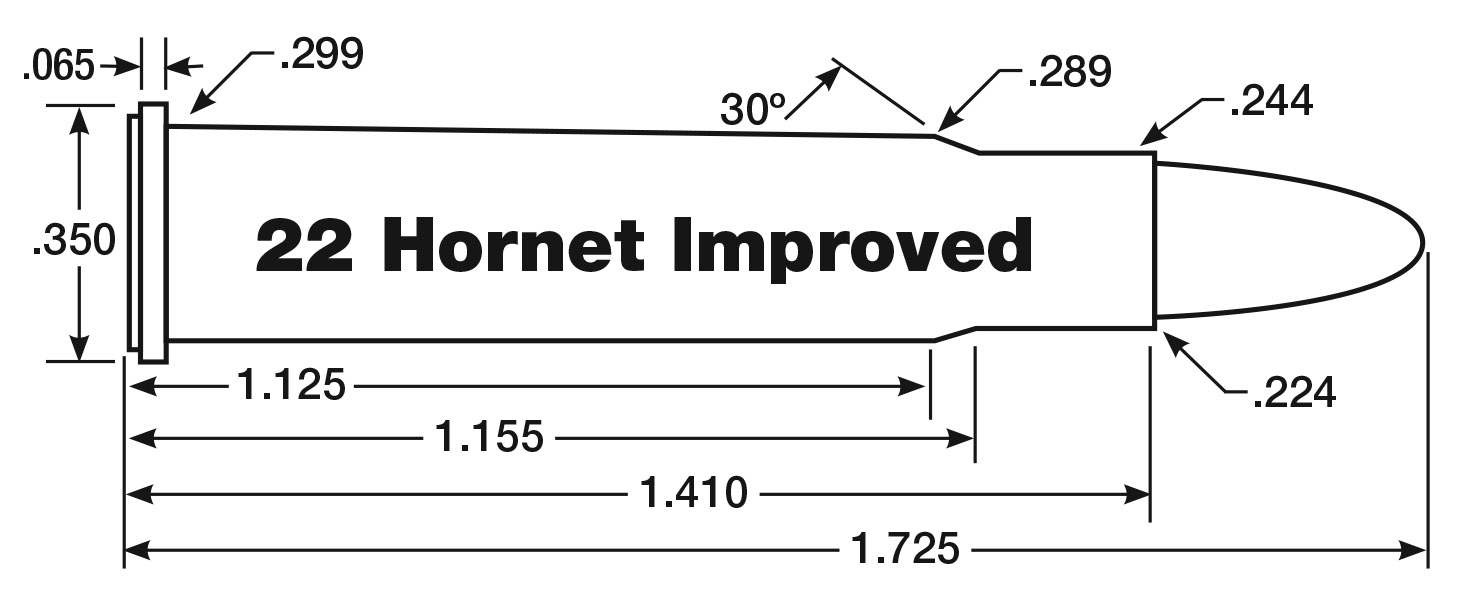

The amount of velocity gained by improving a cartridge depends on the powder capacity gained and it varies considerably with differences in case taper. The 22 Hornet case has an abundance of taper and fireforming it to an improved shape makes room for a bit more powder for higher velocities. Water capacity gain with an improved shape will vary among different brands of 22 Hornet cases, but it is usually less than 10 percent. The Winchester 22 Hornet cases I have average 54.7 grains in weight and have an average gross water capacity of 14 grains. When blown-out to the improved shape for my Winchester Model 70, capacity increased to 15.3 grains for a nine percent gain. Now, how does that translate to velocity gain?

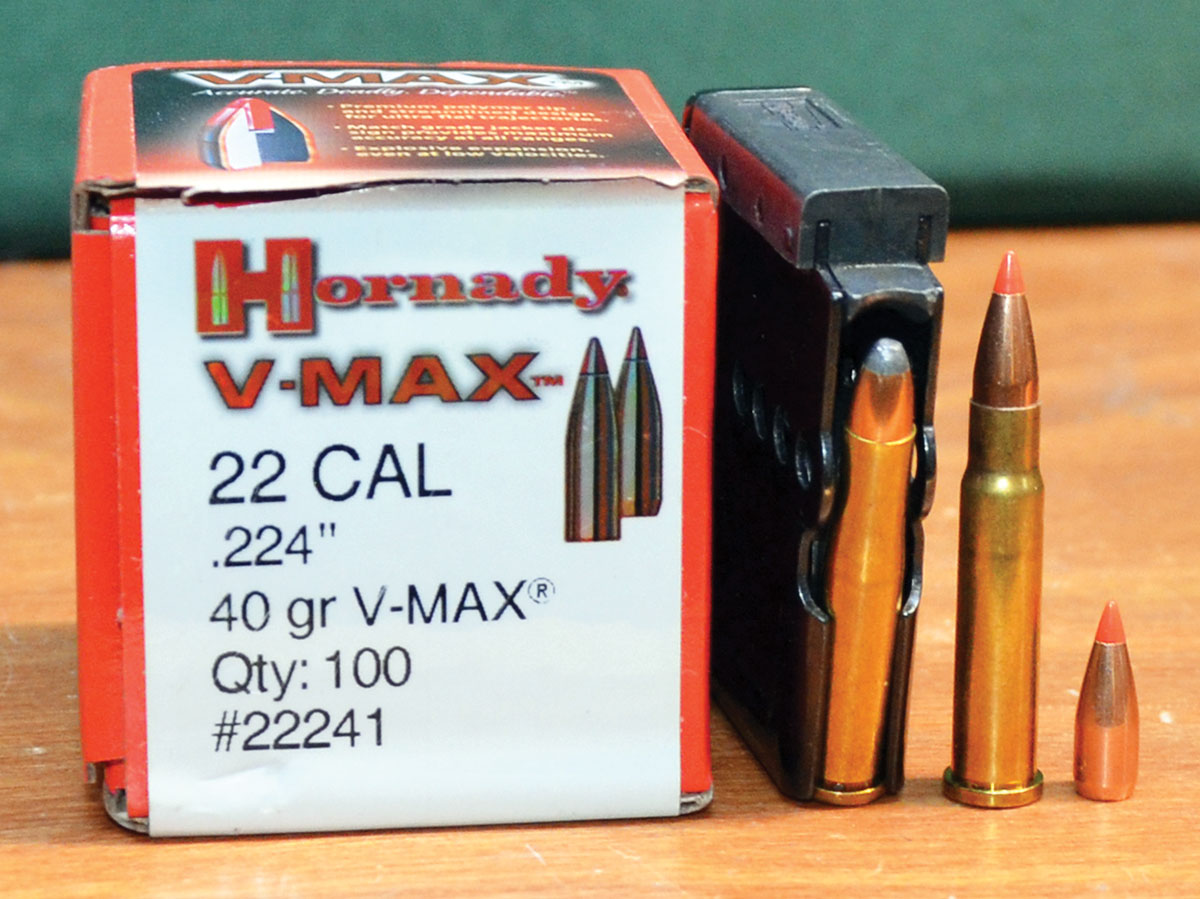

A better comparison is in the 11th edition of Hornady’s Handbook of Cartridge Reloading. The maximum velocities with the 35-grain V-MAX were 3,100 fps for the 22 Hornet and 3,200 fps for the 22 K-Hornet. Respective maximums for the 40-grain V-MAX were 2,900 fps and 3,100 fps. As in the Hodgdon tests, velocity gain increased as bullet weight increased, which is good because I consider 40 grains to be the optimum weight for a bullet in either cartridge. But to be fair and balanced, I must add that barrel lengths used by Hornady were 22 inches for the 22 Hornet and 24 inches for the 22 K-Hornet and that may account for 40 to 50 fps of the velocity advantage shown for the improved version.

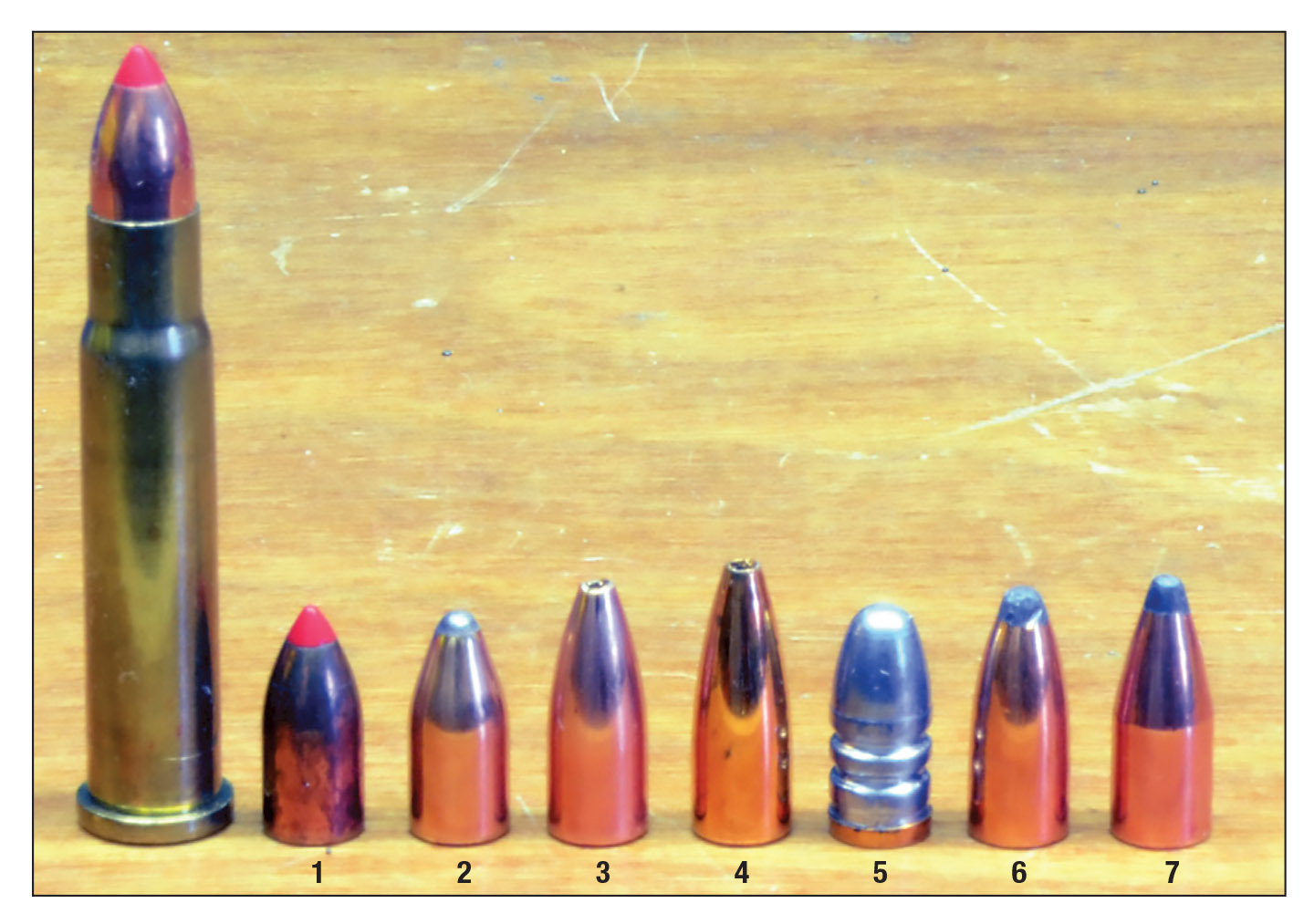

As a rule, relatively short bullets such as the Hornady 35-grain V-MAX and those of softnose design with a maximum weight of 40 grains are the best choices for rifles in 22 Hornet and 22 Hornet Improved. Shooting longer bullets such as the Hornady 40-grain V-MAX and Nosler Ballistic Tip of the same weight is tempting, but they are too long to be completely stabilized by the 1:16 twist of most rifles. Also, seating them with their ogive beyond the mouth of a case results in an overall cartridge length too long for the magazines of most Hornet rifles.

Improved versions of the 22 Hornet have also been popular in other countries. For quite a few years, I wrote regularly for the Australian publication Guns & Game, which was owned, edited and published by my old friend Breil Jackson. An avid hunter, Breil’s primary occupation is farming. His wildcat is an improved version of the 22 Hornet case, but shortened .150 inch to make the overall cartridge length with the Hornady 40-grain V-MAX more compatible with the magazines of various rifles. His rifle has a 1:14 twist and a maximum load with 2400 powder produces a muzzle velocity of just over 2,800 fps with the Nosler bullet.

Through the years, I have accumulated rifles in 22 Hornet made by various American and foreign companies with the Winchester Model 54 and Model 70 being two of my favorites. When finding one with its chamber reamed out for the 22 Hornet Improved, I would shed a tear for future collectors while buying the rifle if the price was right.

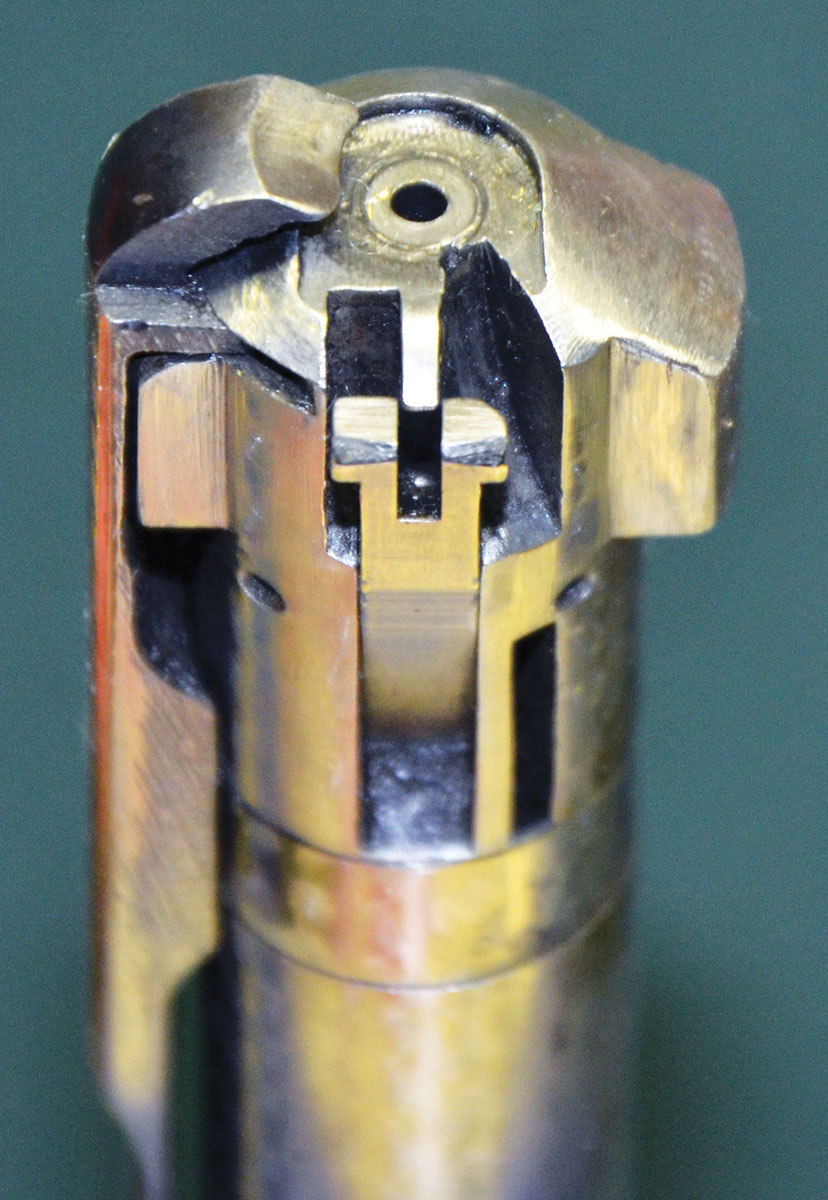

Winchester obviously spent a lot of time and money in order to make a cartridge as tiny as the 22 Hornet feed in actions as large as the Model 54 and Model 70. In addition to drastically shortening bolt travel, a five-round, top-loaded, double-column magazine sized for the small cartridge was fabricated and then fastened to the inside of the regular internal magazine box. The machined-steel magazine follower has a wire-type spring rather than the usual flat spring.

Here is how it all works. The rim of the top 22 Hornet cartridge in the magazine does not protrude upward enough to be contacted by a bolt designed to handle much larger cartridges. The problem was solved in a very clever manner by Albert F. Laudensack, who was granted a U.S. patent for his efforts. As the bolt moves forward, a small, hinged lever at the front of the bolt drops down to contact the head of a cartridge and pushes it far enough forward for the front of the bolt to take over and chamber the round. At that point, the pusher retracts back into its slot in the bottom of the bolt where it remains until cycling is repeated. I have owned Winchester rifles in 22 Hornet for many years and functioning has been flawless for thousands of rounds.

.jpg)

.jpg)