Propellant Profiles

IMR Target

column By: R.H. VanDenburg, Jr. | August, 17

This year, Hodgdon introduced five new IMR powders: IMR Target, IMR Red, IMR Green, IMR Blue and IMR Unequal. They are said to be cleaner burning, to meter better, and several environmentally unfriendly chemicals have been eliminated from their makeup. This latter trend was not started by Hodgdon, but it is nice to see the company join in by doing away with harmful chemicals. Hodgdon has, however, earned a well-deserved reputation for demanding, and getting, its suppliers to adhere to extremely tight manufacturing tolerances. To handloaders, this means more consistent shot-to-shot and lot-to-lot performance. As we shall see, this appears to be true of this new line of IMR powders.

This introduction also helps to explain several Hodgdon moves that have taken place recently. If you remember, the company rebranded IMR-700-X and IMR-800-X as Hodgdon powders, now called Hi-Skor 700-X and Hi-Skor 800-X, which were the original DuPont names. This eliminated any double-base powders from the IMR lineup. The company also dropped – for poor sales apparently – IMR-4759, 7625, 4756 and PB from its single-base line, clearing the way for this new double-base family of IMR powders. These new powders, as are most IMR powders, are manufactured at the General Dynamics-owned facility in Ontario, Canada. Packaging, testing and distributing is done by Hodgdon at its Kansas headquarters.

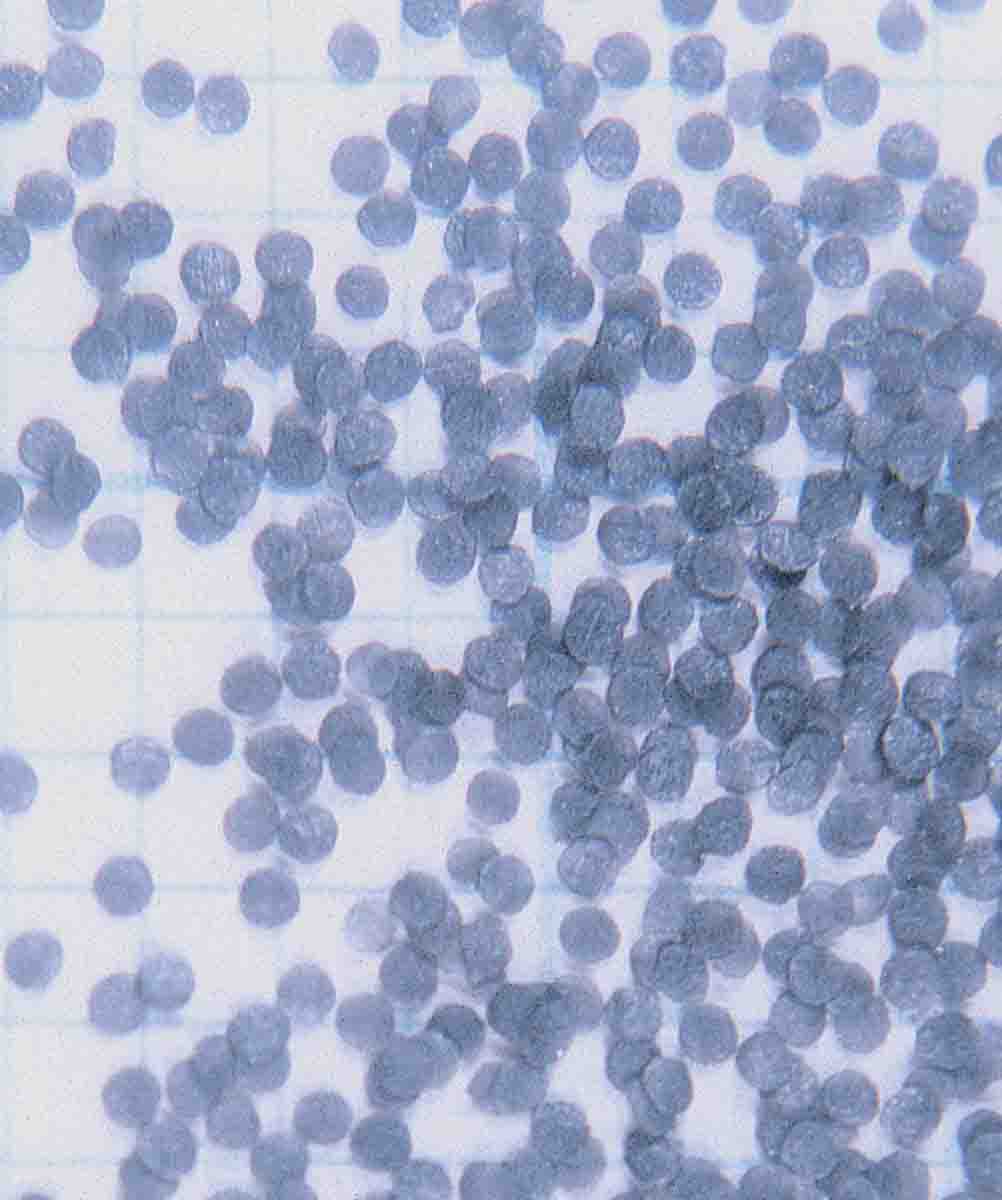

I decided to simply test the powders one at a time, from fastest to slowest, beginning with Target. This is a double-base powder with a nitroglycerin content of 38 percent. It is extruded and cut into very short lengths. Diameter of the kernels is .104 inch; thickness is .004 inch. Bulk density is .630 g/cc. Color is a dark gray. Labeling on its packaging hints at its usefulness in the .32 S&W Long, .38 Special, .44 Special and .45 ACP, although it has a much broader appeal than that.

The powder’s clean-burning nature is difficult to measure. Almost all the loads tested produced relatively low pressure, and no powder is at its best as pressure drops. That said, I witnessed no unburned kernels with either powder, and the one exception to the low pressure, the .40 S&W at roughly 33,000 psi, was very clean burning. Frankly, clean burning is generally of little concern to me, because I tend to clean my guns after use. Exceptions are black powder, of course, and when unburned kernels are found to be getting into the trigger mechanism of autoloading shotguns. In such cases, I tend to be much more critical and careful.

Back to Target. I tested several cartridges with both Bullseye and Target. Target is faster burning and produces slightly higher velocity and pressure. Hodgdon cautions handloaders not to consider the two powders the same and to use only published Target load data. Still, I found Target produced higher velocities, with one exception, and always lower extreme spreads.

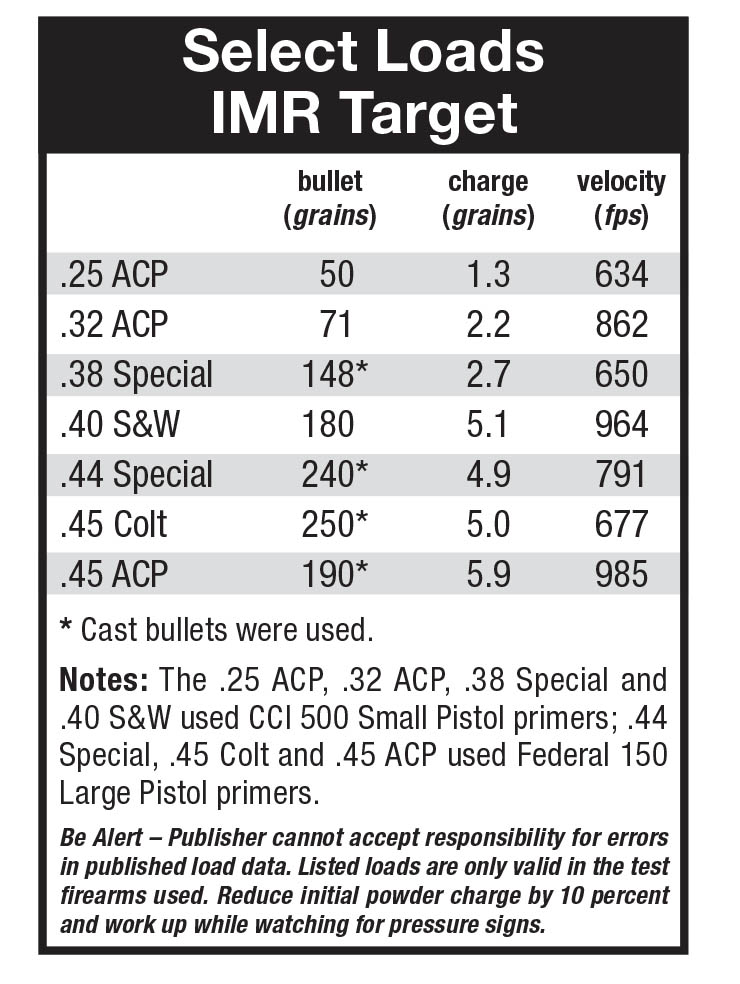

I began with the .25 ACP. This cartridge can be a nuisance to load, and it’s difficult to find expelled cases, but I enjoy small pocket pistols. Testing was restricted to one load with a Winchester 50-grain jacketed bullet. Cases were also Winchester; primers were CCI 500 Small Pistol. Shot-to-shot consistency was very good, with an extreme velocity spread of 19 fps for five shots.

Next up was the .32 ACP, and everything said about the .25 ACP applies here as well. Cases were Remington, primers were the same CCI 500 Small Pistol and the bullets were Remington’s 71-grain FMJ roundnose. Functioning was flawless, and extreme spreads were very small.

Perhaps no handload has served so many for so long as has 2.7 grains of Bullseye under a 148-grain wadcutter bullet in the .38 Special. With Winchester cases and CCI 500 Small Pistol primers, 2.7 grains of Target was used with Hornady 148-grain lead wadcutter bullets. The story repeated itself, with Target producing slightly higher velocities than Bullseye, with smaller extreme spreads and very tight groups.

Remington sells a .40 S&W target load – 180-grain bullet at 980 fps – under its UMC label. Desiring to duplicate it, I came really

The .44 Special test was spot on given the difference in barrel length. Hodgdon’s test barrel was 8 inches; my Ruger has a 45⁄8-inch barrel. Extreme spreads were among the smallest of any throughout the tests. Cases were Remington, primers Federal 150 Large Pistol and bullets were cast lead of 240 grains. Accuracy was excellent.

Sticking with revolver cartridges brought me to the .45 Colt. A 250- grain, .454-inch diameter cast bullet from Meister Bullets capped Remington cases and Federal 150 primers. A handload of 5.0 grains produced velocities in a Colt single action with a 43⁄4-inch barrel that slightly exceeded the same charge of Bullseye and, once again, produced smaller extreme velocity spreads and gave certainly serviceable accuracy. This was not, by any means, a maximum load, simply an age-old one chosen for comparative purposes. The maximum would be about 6.5 grains of Target and could prove to be a better one.

A final test was with the .45 ACP. By now I felt I knew what to expect and was not disappointed – small extreme spreads and tight groups. My load employed Remington cases, Federal 150 primers and 190-grain cast bullets. It could easily be reduced for target purposes, especially at shorter distances, but performance was excellent.