From The Hip

Freedom Arms Model 83 .454 Casull

column By: Brian Pearce | October, 18

In 1983 Freedom Arms began offering a large-frame, single-action revolver for a proprietary .454 Casull cartridge. In addition to several innovative features, the Model 83, as it became known, offered new levels of power, strength and accuracy. After 35

In 1954 Dick Casull was working for P.O. Ackley building custom guns, barrels and performing destructive testing on a variety of firearms. Fascination with powerful and accurate sixguns resulted in his converting a 1904-era Colt Single Action Army to a wildcat .44 Magnum prior to Remington introducing its commercial .44 Magnum in December 1955.

Casull had become aware of the frame and cylinder variances in Colt SAA revolvers that made achieving perfect chamber-to-bore alignment difficult, but is essential to achieve top accuracy. To solve this problem, he cleverly devised a method beginning with a small-caliber cylinder of his own manufacture (as well as Colt’s) and bored each “hole” from the front of the frame through the threaded “receiver” with the aid of a bushing. The cylinder was then finish chambered from the breech end to correspond with a given cartridge. This “line boring” method removed possible chamber alignment errors with the center axis of the bore. The wildcat .44 Magnum Colt SAA was the first revolver to be line bored. Casull also experimented extensively to achieve unusual steel strength that included double heat treating. To form cases he started with .30-40 Krag (.30 U.S.) brass that was cut down to essentially the same length as the commercial .44 Magnum at 1.285 inches, then slightly modified the rim diameter. Using 245-grain (Linotype) cast Keith-style bullets, velocity reached over 1,500 fps from the 7.75-inch Ackley barrel.

Recognizing strength limitations with frame size and design of the Colt SAA, Casull obtained a block of 4140 steel and crafted a large-frame, five-shot, single-action revolver of his design. It was double heat-treated and fully blued with fancy walnut stocks, sported a 7.5-inch barrel and was chambered for the lengthened .454 Casull (.454 Casull Super Magnum). Casull now had the vehicle to achieve the ballistics he wanted and soon pushed 225-grain bullets over 2,100 fps. More practical loads included 260-grain bullets at 1,900 fps or 300-grain bullets at 1,700 fps. The year was 1957, and this was the first full-length .454 Casull cartridge that is similar to the industry-standardized version known today.

Over the next couple of decades a number of custom .454 revolvers were built mostly on Ruger Super Blackhawk frames fitted with five-shot cylinders and custom barrels. However, the ultimate goal was to begin manufacturing high-quality guns and ammunition. After a number of false starts, along with obtaining patents, Casull cofounded Freedom Arms with the help of Wayne Baker in 1978. The .454 Casull was a proprietary cartridge, so they tooled up to manufacture guns and ammunition. Vintage factory loads listed a 300-grain JSP bullet at 1,600 fps, a 260 grain at 1,800 fps and a 240-grain load at 1,875 fps – actual velocity figures almost always exceeded claimed velocities.

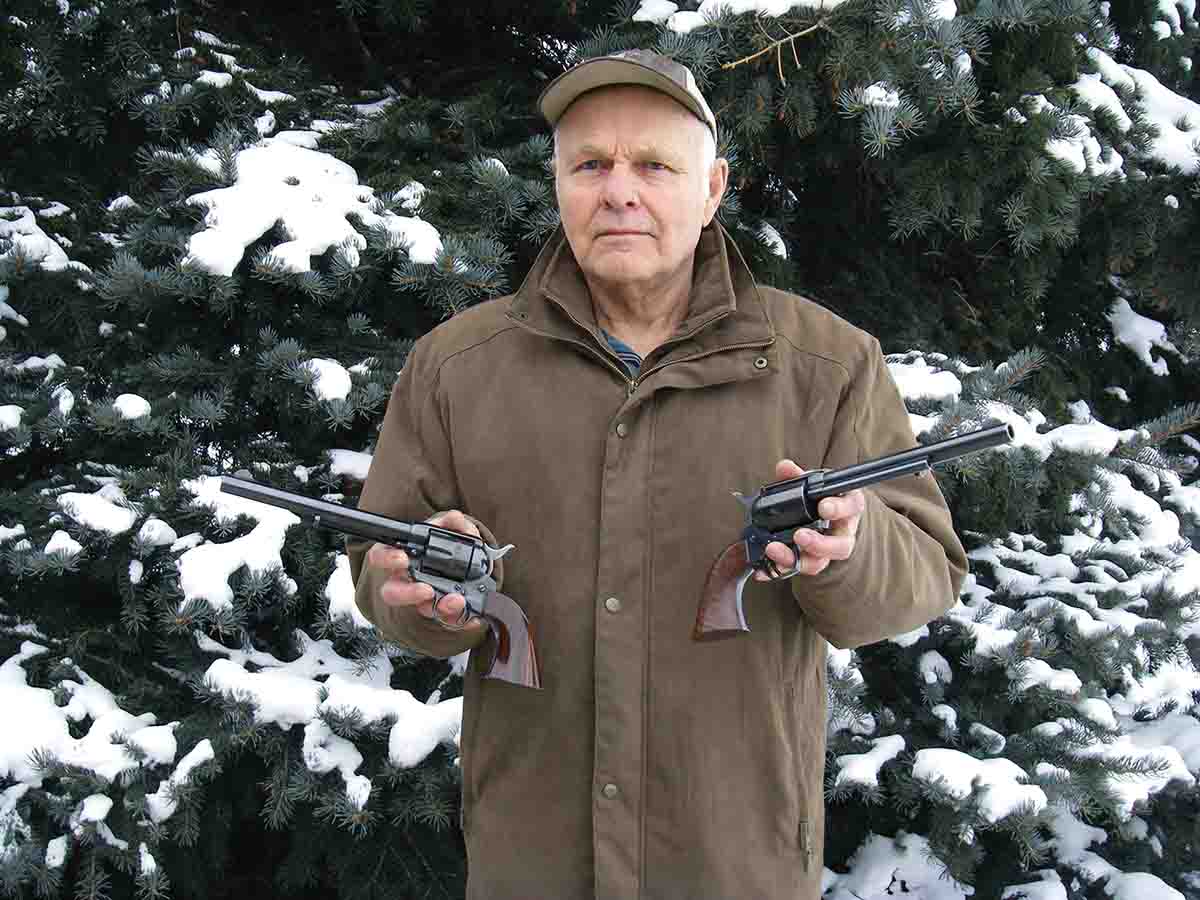

The Model 83 was a huge leap forward in quality, accuracy and innovation. In 1983 and 1984, I had the chance to examine, fire and develop handloads for one of the first

In the past 35 years I have used Model 83s to take elk, whitetail and mule deer, black bear, feral hogs, javelina and other game. In the hands of other hunters, it has accounted for the world’s largest and most dangerous game.

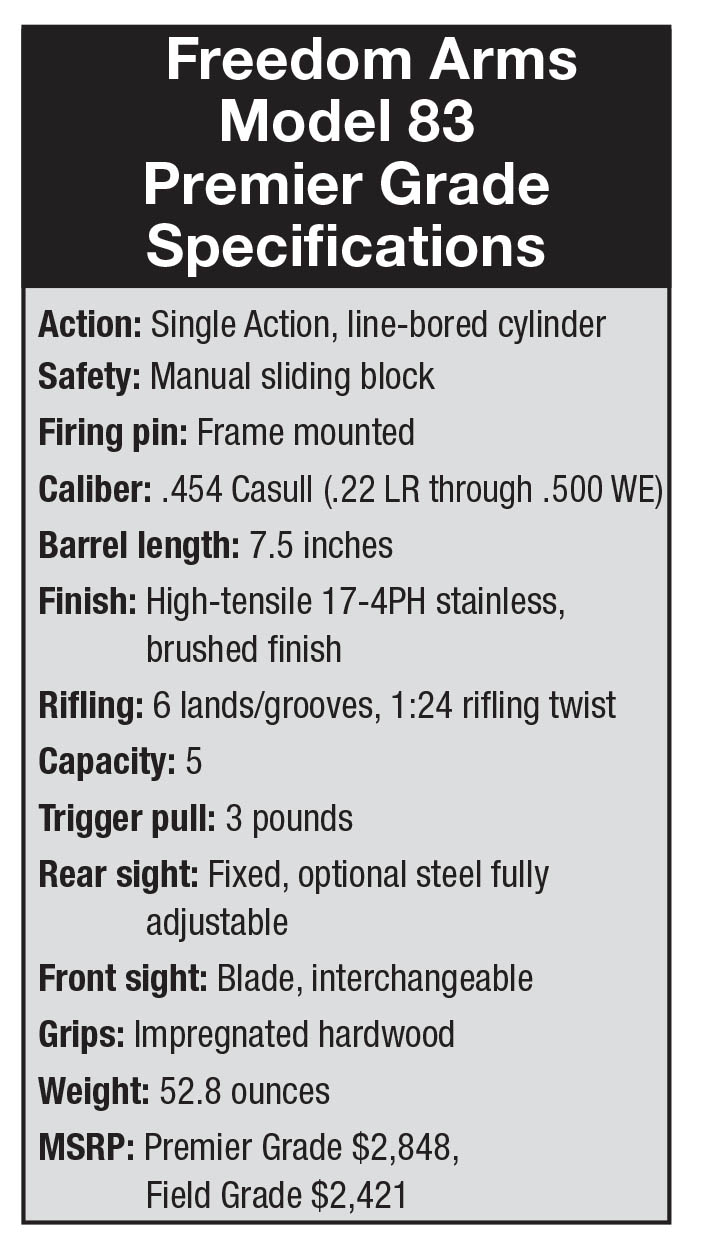

The Model 83 revolver displays beautiful machine work and is completely hand fit and finished. The barrel/cylinder gap is always held to a maximum

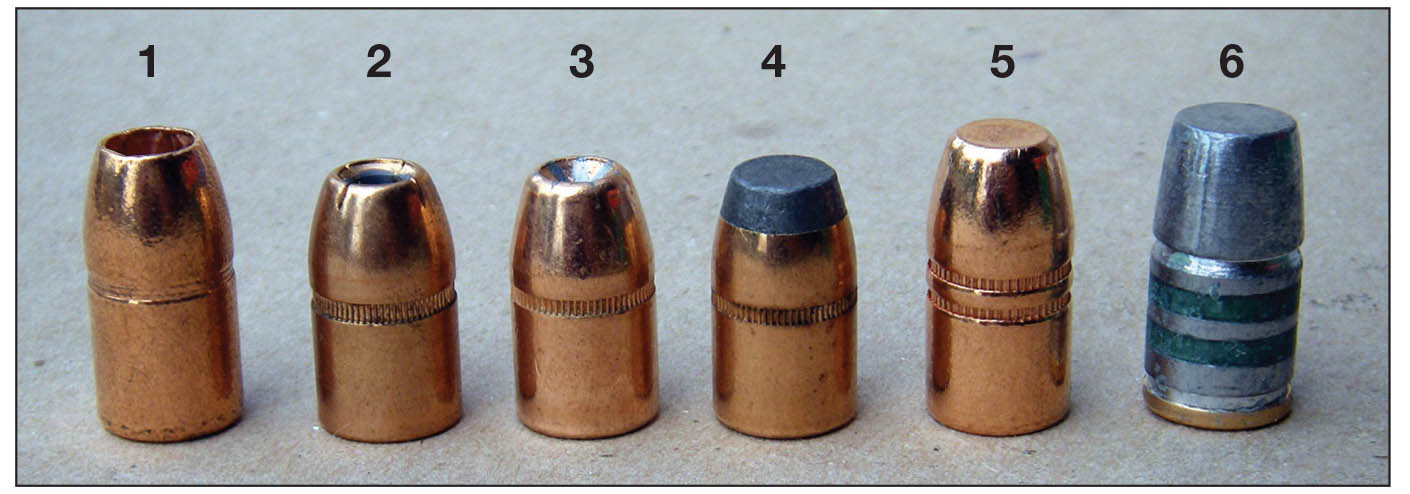

Chambers are cut to minimal dimensions and are finished to a bright, mirror-like appearance. The throats measure .452 inch, which help minimize bullet deformation and serves to keep cast and jacketed bullets straight while transitioning into the forcing

Internal springs consist of both coil (piano wire) and leaf designs. There is a manually engaged, hammer-mounted, sliding block safety that is positive. As a result, I suggest carrying only four cartridges (which is plenty for hunters) with the hammer down on the empty chamber. The basepin head is drilled and tapped to accept a setscrew that extends into a small hole drilled into the bottom of the barrel, which serves to positively hold the basepin in place when subjected to heavy recoil.

While a fixed-sight version is offered, adjustable sights are most popular. The screw-adjustable rear sight on the Premier Grade is constructed of machined steel and is a robust design. It is easily removed to allow the installation of a scope mount base. The front sight is housed in a ramp-style base and is secured with a setscrew from the front. It is easily changed to achieve various sight pictures or different heights to accommodate a variety of loads.

In an effort to offer a slight increase in space between the second finger and the trigger guard to prevent contact during heavy recoil, the current grip frame is a slight redesign from early production revolvers. Regardless, the grip frame is designed to position the hand and wrist to easily handle the stout recoil.

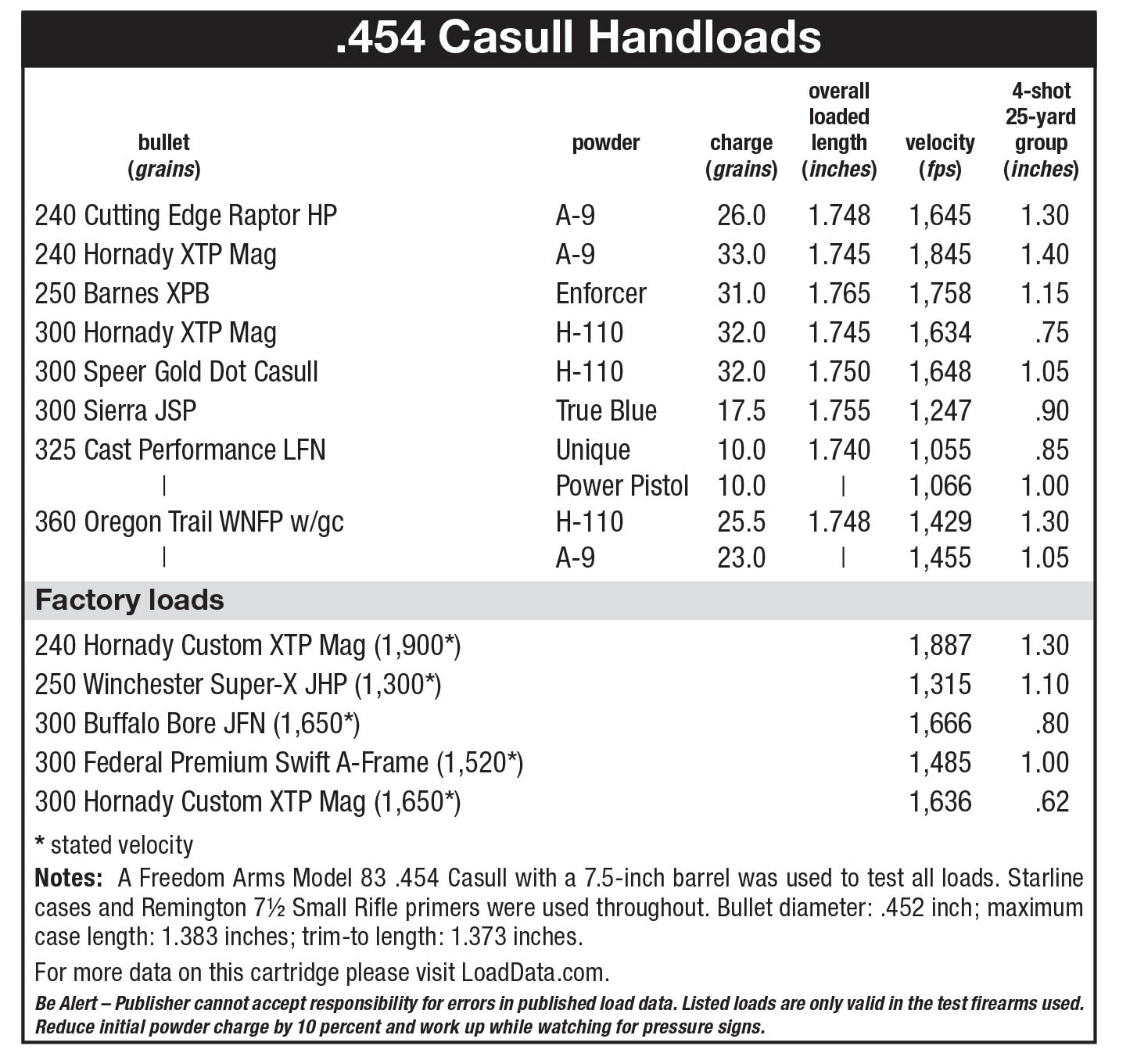

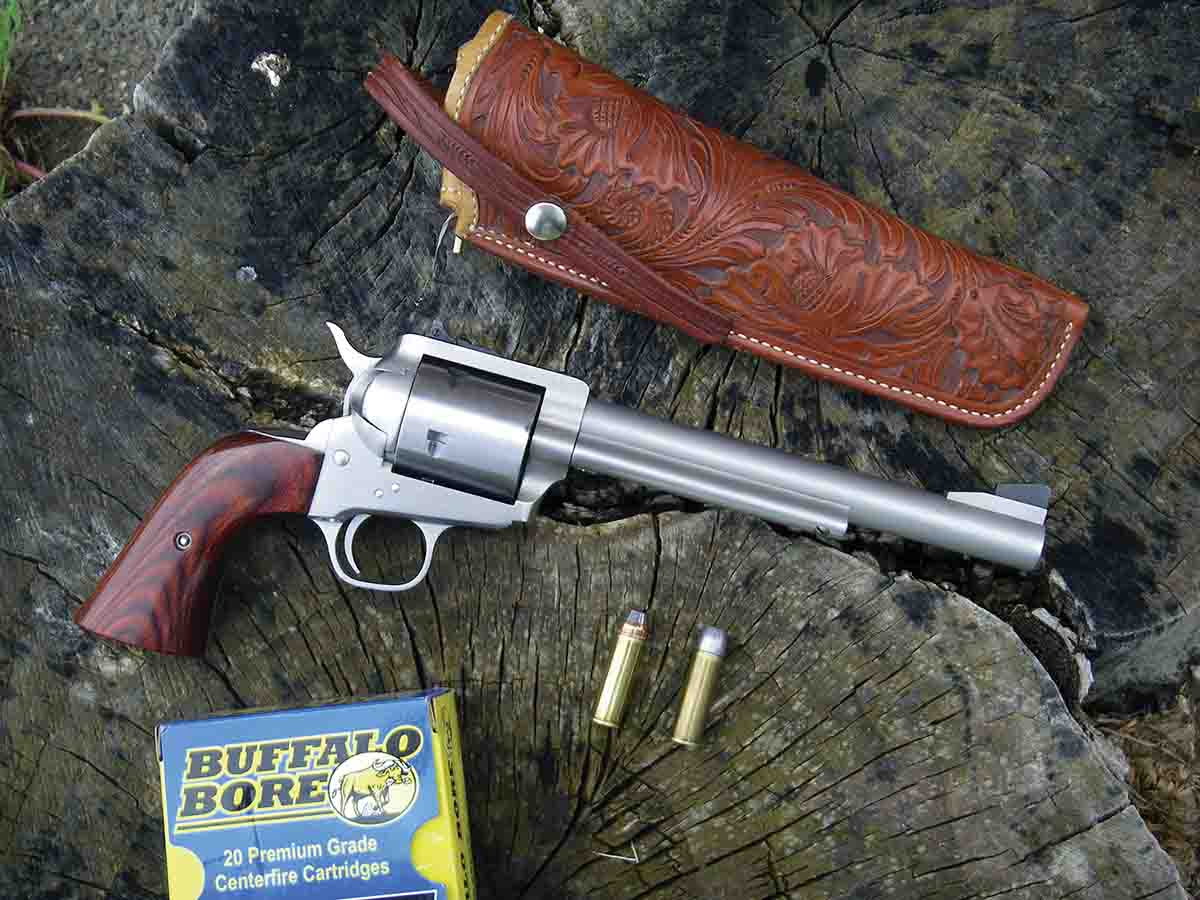

In 1998, the .454 became a standard SAAMI cartridge with a maximum average pressure of 65,000 psi. Select .454 Casull factory loads from Buffalo Bore, Federal, Hornady and Winchester were checked for accuracy and velocity in a Model 83 with a 7.5-inch barrel. All factory loads managed to place four shots (measured center to center) inside 1.30 inches at 25 yards. The smallest group was produced with Hornady’s 300-grain XTP Mag loads at 1,636 fps, which cut a ragged hole measuring .62 inch.

Handloads containing both cast and jacketed bullets were assembled. A few tips when assembling .454 Casull ammunition include using cast bullets sized to allow them to pass through the throats, or loaded cartridges may not chamber. The die’s expander ball should never measure more than .448 inch, with .446 inch being advantageous as it increases bullet pull, which aids with powder ignition and prevents bullets from jumping crimp due to heavy recoil. Depending on seat/crimp die design, either a heavy roll crimp or a neck down crimp should be applied. Always use small rifle magnum primers such as the Remington 7½, Federal 205 or CCI 450, which serve to offer reliable ignition and feature cups thick enough to handle the high pressures associated with this cartridge. Jacketed bullets of heavy construction should be selected to withstand the associated pressures.In addition to offering factory duplication handloads containing 240- to 300-grain jacketed bullets, cast bullets were also used. Included are midrange loads that are comparatively pleasant but capable of taking big game.

Over the years I have owned and fired dozens of Model 83s that have, without exception, proved extremely accurate. One of my revolvers has fired more than 10,000 rounds of full-power loads and remains tight and accurate. The Model 83 is indeed a most remarkable revolver.

***

Richard "Dick" Casull

On May 6, 2018, Richard “Dick” Casull passed away at age 87. His contributions to the firearms industry were extensive. In addition to developing line-bored revolvers and cofounding Freedom Arms, he designed several patented bolt-action rifles and cartridges, fully automatic open-bolt rifles for military use, a rifle capable of launching a bullet 10,000 fps without a case, aluminum pillar bedding, etc. He assisted with technical research and development for several major gun companies. He held 22 firearms patents and 191 claims.

Dick often told stories of his younger years, some of which are probably best not repeated. However, he was taught honesty, integrity and to have a genuine concern for others. Growing up during the Great Depression, he did not have money to buy a bicycle, so he went to a scrap yard and obtained all the parts to make his own. He designed and built his first gun at age 11. While in his early teens he learned handloading. When he was “about 15,” he rode his horse deep into Mexico and returned mostly unharmed, but much wiser. While working for P.O. Ackley, he improved his machining skills and expanded his experience with a variety of firearms and cartridges. When he met Jeri, he had the good sense to marry her. He was a master pilot. In 1988 Dick received the “Outstanding American Handgunner” award, which he treasured.

While Dick will mostly be remembered for his many contributions to the firearms industry, those who knew him well will miss him for his genuine friendship. I recall a particular gathering where a young couple had traveled a long distance to attend. When they arrived they began having car troubles and were short of funds to make the repairs and return home. Dick took care of their needs without expecting anything in return. Dear friend, you are sorely missed by many.