Propellant Profiles

Winchester 244

column By: R.H. VanDenburg, Jr. | October, 18

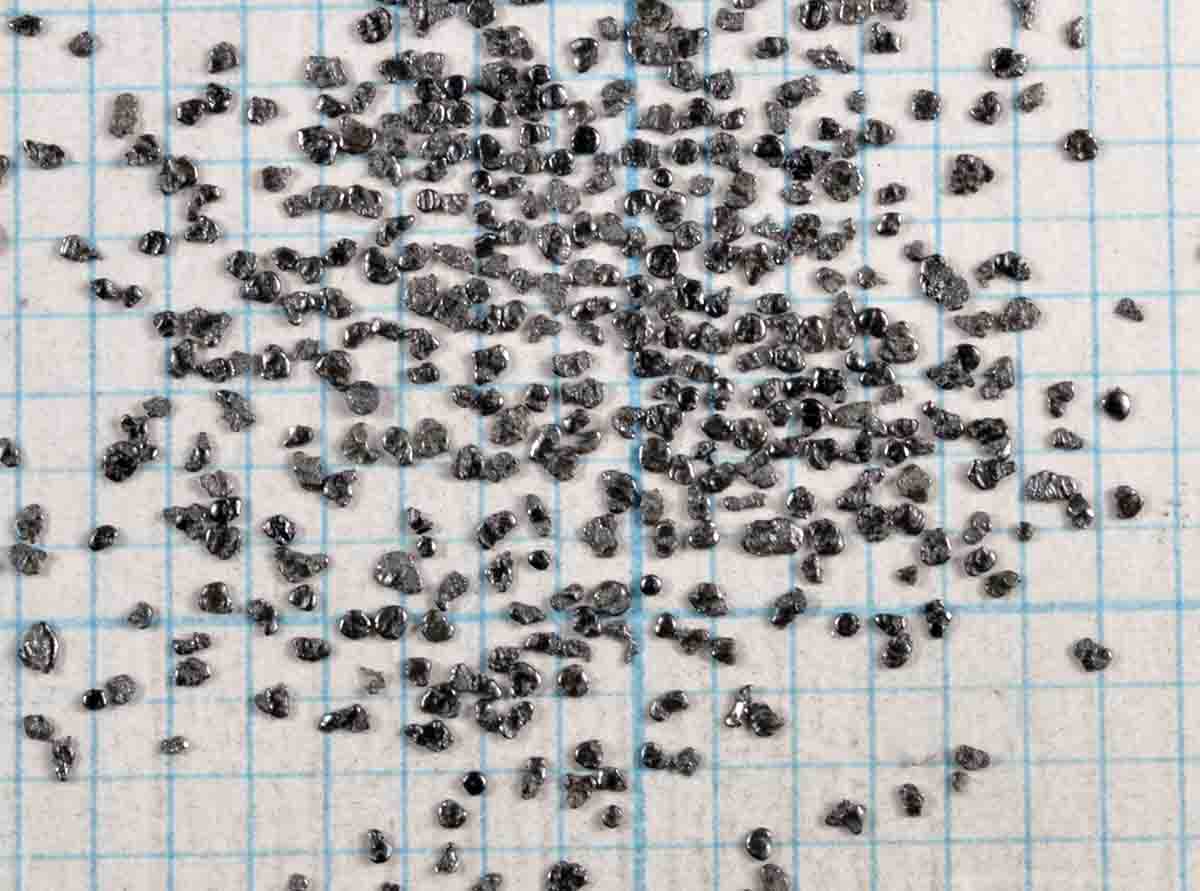

Ever since Hodgdon Powder Company entered into its agreement with Olin Industries in 2005 to develop and market Winchester powders, the product line has seen constant improvement. The most recent addition is Winchester 244, a midrange handgun propellant with a number of modern improvements.

To begin with, W-244 is promoted in Hodgdon’s Basic Reloading Manual as suitable for target, light-duty and medium-duty use in handguns. In its Relative Burn Rate chart in the same manual, Hodgdon HP-38 and Winchester 231, which are the same powder, are shown in positions 28 and 29, respectively. Separated by only Alliant 20/28 at No. 30 is Winchester 244 at No. 31. On the previous page where Winchester powders are listed in order of approximate burning rate from fastest to slowest, W-244 appears before W-231. Clearly the burning rate of the two Winchester powders are similar, but the load data in the same manual suggests that W-244 is slightly faster burning than W-231, at least with most cartridges and bullet weights.

While the above manual data is somewhat limited, Hodgdon’s Annual Manual 2018 lists W-244 in just about every cartridge from the .25 ACP to the .45 Colt. Most of those cartridges omitted list W-231 or HP-38 instead, suggesting W-244 was simply not laboratory-tested but is still suitable.

Winchester 244 is manufactured in the St. Marks Powders facility in Florida, where all Winchester powders are made. The facility was, until spun off and sold by Olin Industries (Winchester’s parent), a Winchester operation. It is now a part of military contractor General Dynamics.

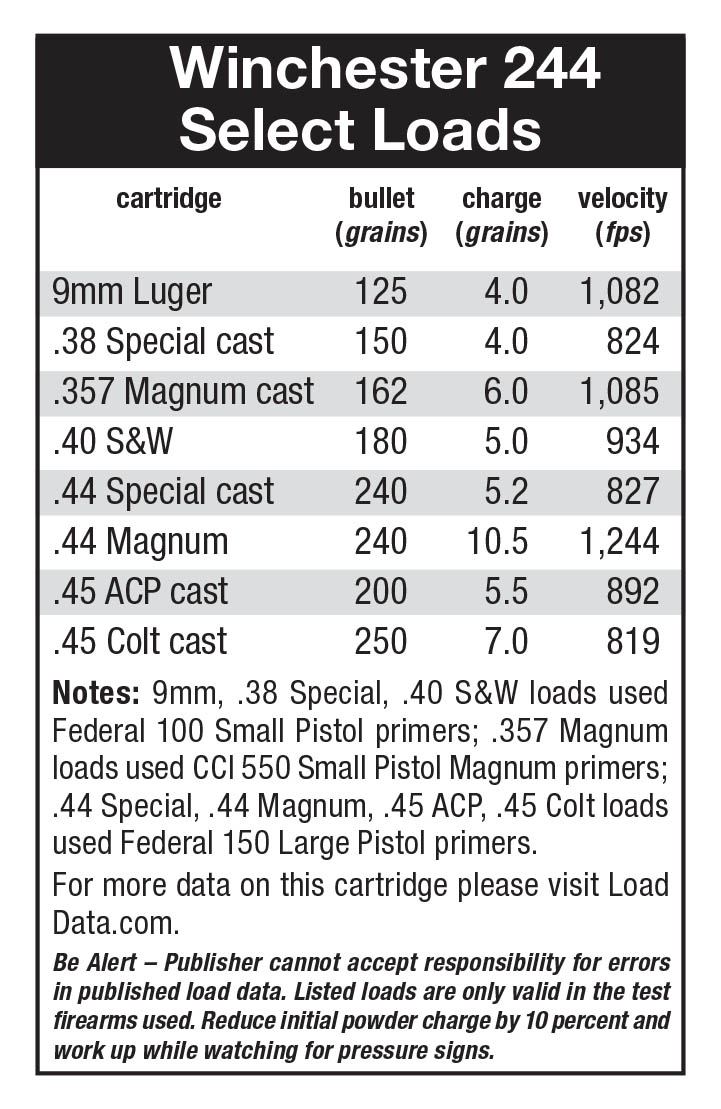

Since the powder is so versatile, I had to limit my cartridge selection but tried to cover the most popular choices. In the 9mm Luger I stayed with the Sierra 125-grain bullet and had excellent results with modest-sized groups commensurate with this gun’s capabilities.

When it came to the .38 Special and .357 Magnum, the same revolver was used for both cartridges, a Ruger Security-Six shooting cast bullets. The .38 Special was matched with 150-grain bullets from Lyman mould No. 358477, and the .357 Magnum was loaded with 162-grain gas check bullets from RCBS mould 358-158-SWC. Both performed very well with W-244. Differences in my 4-inch barrel and the test barrel of 7.7 inches in the .38 Special and 10 inches in the .357 Magnum are reflected in my velocities. Hodgdon called for a small pistol magnum primer in the .357, which I complied with, but it’s doubtful it was really necessary given the fast burning powders listed in the data. Still, it’s best to listen to the professionals.

In the .40 S&W with its relatively small case capacity, I saw the consistency alluded to earlier with an extreme velocity spread of one fps. Groups at 25 yards were not that small but were quite acceptable. The bullet used was the Sierra 180-grain hollowpoint.

I also used only one revolver for the .44 Special and .44 Magnum – an ever-faithful Ruger Super Blackhawk. In the Special, I

To test .45 ACP loads, I dug out a Colt Government Model and filled the cases with 200-grain bullets from Lyman mould No. 452460. My preferred load was somewhat under maximum but gave good accuracy. Purely for target purposes, the load could be cut even more.

It was with the .45 Colt where I recorded additional superior results with a five-shot extreme spread of 5 fps. The charge of 7.0 grains was not maximum, but the results spoke for themselves. The barrel length on the test revolver was 4.75 inches; the bullet was a Meister Bullets 250-grain SWC.

All in all, to say that this new powder is impressive would be an understatement. If a handloader is looking for a versatile, clean-burning handgun powder with excellent metering qualities, a decoppering agent and a flash retardant, he might want to give this new Winchester 244 a try. It is available in one-, 4- and 8-pound containers.