Propellant Profiles

Shooters World AR-Plus

column By: Randy Bimson | February, 21

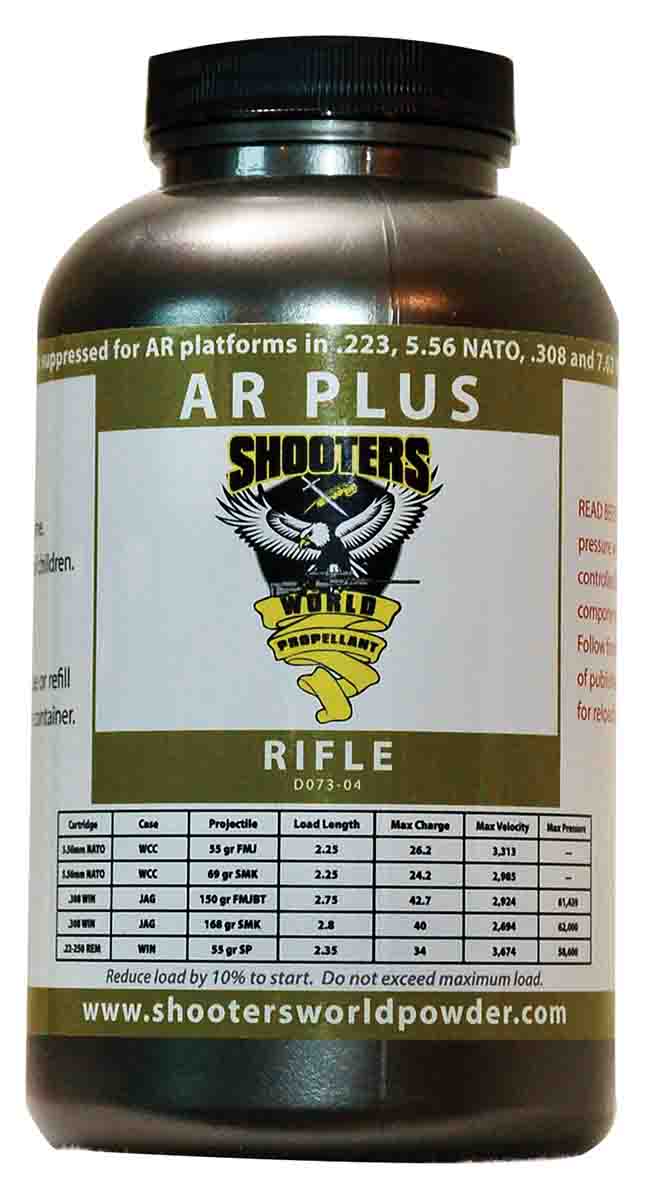

With that in mind, Shooters World (SW) set its sights on targeting Hodgdon’s 1960’s-era spherical H-335 propellant, a long-standing favorite of people who load small to midsize rifle cartridges. AR-Plus was developed for shooters who are looking for optimum performance using 55/62-grain bullets in appropriately chambered .223 Remington or 5.56 NATO rifles, or the standard 147/150-grain bullets in .308 Winchester or 7.62 NATO chambered rifles at industry standard velocities.

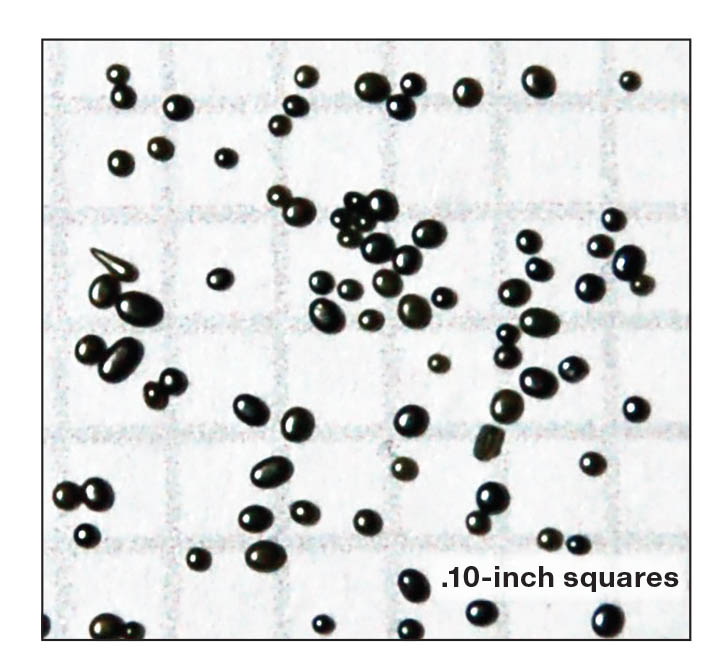

AR-Plus is a spherical propellant manufactured for SW by Explosia Company in Pardubice-Semtín of the Czech Republic. Explosia is also the manufacturer of the Lovex line of propellants marketed extensively in Europe. AR-Plus is a very fine-grained, double-base propellant. The tiny AR-Plus spherical grains measure an average diameter of .0145 inch and are a shiny gray-black color. The propellant has a very high bulk density of .99g/cm3.

It is quite possible more spherical powders have been used in the quest for prairie dogs than any other propellant type. From the heyday of the .222 Remington to today’s darlings, the .223 Remington and 5.56 NATO, spherical powders have been indispensable propellants for many a varmint hunter. Combine that with the popularity of three gun matches and the general recreational shooting of .223 Remington, 5.56 NATO, .308 Winchester and 7.62 NATO rifles, it amounts to a lot of high-volume shooting. High-volume shooting equates to high-volume reloading, and the smooth and consistent metering characteristics of spherical powders have won many a reloader’s heart.

The very small grain diameter of AR-Plus makes for exceptionally smooth and consistent metering characteristics for use with powder measures and progressive loading tools. To validate that statement, a finely-machined Neil Jones Custom Products measure was used to throw 20 charges of 25 grains by weight. The difference in charge weight from the lightest to heaviest of the 20 charges was .01 grain, as verified on an Ohaus/RCBS 10-10 beam scale and a Lyman Pro-Touch 1500 electronic scale.

Currently, there are two main sources for AR-Plus load data, the SW reloading guide and the Lovex reloading guide, both of which are available online at shooters worldpowder.com. The data varies in that SW data is developed using the Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI) process and protocols, and Lovex using Commission International Permanente (C.I.P.) process and protocols. While their respective processes and protocols differ in some principal areas, the recommended starting charges result in chamber pressures for a specific cartridge and test barrel that fall within industry accepted standards. It is incumbent upon the reloader to progress in a safe manner. Always start load development with the recommended starting charge and work the load up to higher pressures, never exceeding the published recommended maximum charge weight.

According to Shooters World’s burn rate table, AR-Plus falls in the range of Hodgdon H-335, spherical Accurate 2230 and extruded IMR-3031. The propellant is adaptable to a good number of cartridges from .222 Remington through .308 Winchester, and also works in straight-walled rifle cartridges like the .458 Winchester Magnum and .458 SOCOM, although data has not been published on the later two yet.

The performance attributes that SW focused on with the introduction of AR-Plus to the reloading market are a cleaner burn, reduced velocity and pressure variations due to powder positioning, muzzle flash and temperature stability.

I have shot a considerable number of rounds in calibers that I consider AR-Plus as being a very appropriate propellant for: .223 Remington, 5.56 NATO, .308 Winchester and .303 British – all calibers I have used Hodgdon H-335 very successfully in for many years. For the purpose of this column, the focus was on the .223 Remington and .308 Winchester.

In .223 Remington I chose my go-to coyote rifle of long-standing, a DPMS 20-inch, heavy-barreled Arctic Panther with left side FN-FAL type cocking handle high-rise upper, laminated JP Enterprises thumbhole stock and a JP trigger topped with a Burris Signature 6-24x scope. This rifle shoots five-shot groups around .600 inch day in and day out with a load comprised of 24.9 grains of H-335, a Remington 7½ primer and a Nosler 55-grain Ballistic Tip. Change the propellant charge out to 24.7 grains of AR-Plus, and accuracy is comparable and muzzle flash is considerably reduced.

The above two .223 Remington loads also deliver excellent accuracy, five-shot .850-inch groups at 100 yards, from a Lewis Machine Tool CQB16 piston drive 5.56 NATO carbine. Again, the muzzle flash was considerably reduced when shooting rounds loaded with AR-Plus. When using the AR-Plus in both the above rifles mechanical function was spot-on, indicating a good gas volume/port pressure balance.

For .308 Winchester testing, I chose my Mannlicher-style stocked Ruger M77. This little rifle is very opinionated with regard to what bullet/propellent combinations it likes. Up until this date, I have had only one load with which the rifle delivers what I consider excellent accuracy for its intended purpose as a hunting rifle, three-shot groups just under an inch at 100 yards, with a load consisting of 43.2 grains of H-335 behind a 150-grain Nosler Ballistic Tip bullet lit up by a Remington 9½ primer.

.jpg)

“Temperature stabilized” propellants help to reduce one more adverse effect on external ballistics, change in velocity relative to ambient temperature changes. In my opinion, at what I consider long hunting ranges, 400 to 500 yards, to a lesser affect than wind drift and mirage reading, but that being said, anything that helps and you don’t have to think about is a bonus worth the taking.

Spherical powders have traditionally been more challenging to engineer with a greater insensitivity to ambient temperature changes. Shooters World AR-Plus joined the marketplace, along with Winchester StaBall 6.5, as one of the few temperature stabilized spherical powders. Shooters World’s Ken Johnson shared the following test data for comparative loads of H-335 and AR-Plus: H-335, ambient temperature change 78 degrees Fahrenheit to 150 degrees Fahrenheit; 137 fps velocity and 9,188 pounds per square inch pressure increase. AR-Plus, ambient temperature change 78 degrees Fahrenheit to 150 degrees Fahrenheit; 51 fps velocity and 3,805 pounds per square inch pressure increase.

One cause of external ballistics variables that is most often overlooked by shooters seeking to get the most consistent accuracy is “powder positioning,” or more relatively put, powder against bullet (PB) or powder against primer (PP). As the recently retired director of technical affairs and technical advisor to SAAMI, one of my responsibilities was overseeing the development and maintenance of the SAAMI American National Standards, as affirmed by the American National Standards Institute. These industry standards establish the characteristics, procedures and equipment used in creating the pressure and velocity performance and dimensional characteristics for commercially manufactured ammunition. One of the main points of procedure in the pressure and velocity testing of ammunition is the protocol to ensure the consistent orientation of the powder charge within the cartridge case for each and every test round fired. Failure to do so will result in differences, in some cases significant, in pressure and velocity.

Test lots loaded with comparable charges of AR-Plus and H-335, powders that have virtually the same bulk density and take up the same amount of physical space in a given cartridge case, revealed the following results: 100 fps difference between powder-to-primer positioned lots and powder-to-bullet positioned lots for H-335; 58 fps difference between powder-to-primer positioned lots and powder-to-bullet positioned lots for AR-Plus.

The 42-fps velocity difference between the H-335 test lots and AR-Plus test lots is not earth-shattering, but if you are an accuracy nerd, it is a freebee there for the taking if you chose to load AR-Plus.

Subjectively, based on bore fouling and powder residue in the action of the two self-loading test rifles, I would give the nod to AR-Plus being a cleaner burning powder than H-335.

Hodgdon’s H-335 has been doing what it does well, shooting tiny groups from a variety of small and midsized rifle cartridges fired from manually-operated and self-loading rifles, for the past 60 years and I see no reason for that to change. AR-Plus is the new kid on the block, but it is proving to offer excellent accuracy potential with some additional fringe benefits that H-335 does not offer. Will it replace my tried and true H-335 loads, not likely.