Reloader's Press

Utility Loads

column By: Dave Scovill | August, 18

Reviewing years of correspondence with readers of this column and the now-defunct cast bullet column of the late 1980s, it is apparent that most, if not all, folks are interested in “good, accurate” loads with powders and bullets on hand for the cartridge of interest.

An example of a utility bullet in the .45 Colt is the almost ancient Remington 250-grain, .455-inch, conical flatnose, swaged-lead slug featured in Remington, Remington/UMC or UMC factory loads over various charges of black and smokeless powders for well over 140 years. Prior to the 1970s or thereabouts, it had a bowl-shaped (.3-inch wide by .1-inch deep) hollowbase cavity. Currently, however, the component version is the same bullet found in Remington factory loads with a concave base.

Winchester’s counterpart to Remington measures .456 inch and weighs in at 255 grains in factory loads with a cone-shaped base cavity that until a few years ago was available as a component. The Remington slug has a graphite/waxy coating; the Winchester version features a clear lubricant of some sort.

To date, judging from the number left in the third of three boxes of Remington RNFP bullets ordered from Huntington Die Specialties over that last 30 years or so, I’ve shot something close to 2,300 of them in various smokeless and black-powder loads.

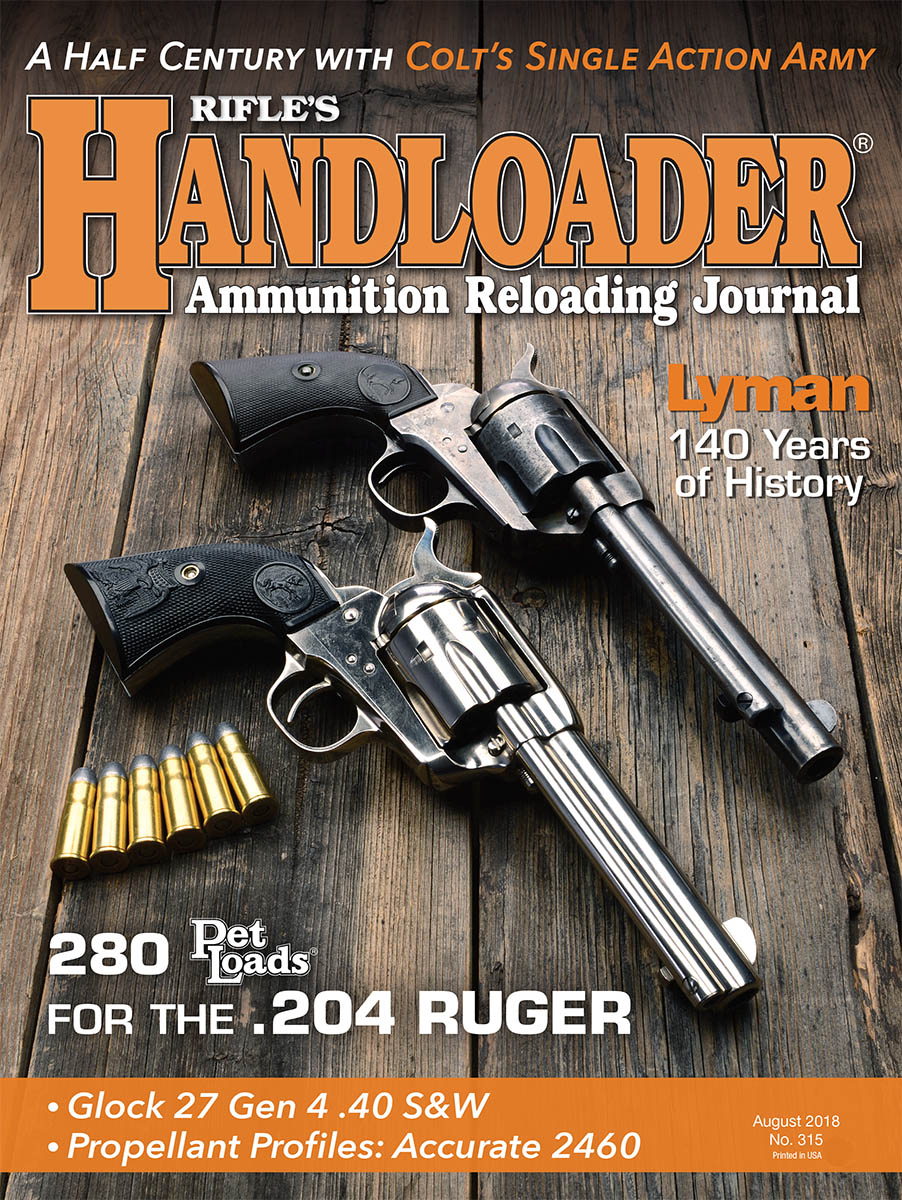

Early interest in the Remington factory loads with the 250-grain swaged-lead RNFP was sparked in 1973 by a Colt SAA with a new .45 Colt cylinder and a 7.5-inch barrel from Numrich Arms, now Gun Parts. The first three shots formed a tidy cluster at 20 yards or so, and they have been a standard go-to bullet in utility handloads since the first box of 1,000 was ordered from Huntington.

The gun of choice was the newly introduced (1971) Ruger Blackhawk .45 Colt, that at the time had .451- to .452-inch chamber throats and .451-inch barrel groove diameters. Moreover, much of the enthusiasm surrounding the Ruger Blackhawk was its application for hunting big game with stout hunting loads up to 30,000 psi. All was well and good but completely ignored Colt SAA .45s, leaving the impression that, as a well-known handgun editor told me at the time, to paraphrase, no one in their right mind would consider hunting with an old Colt black-powder-era relic, aka cowboy gun, with open sights that was hardly appropriate for small game or varmints, let alone deer-sized game. Of course, that also applied to Italian Colt replicas, which had just started to sell like hotcakes in Europe and North America and by the early 1980s inspired the rapid spread of cowboy action shooting (SASS).

Enter the old Lyman 310 tool with a neck expander that measured .4515 inch as a stopgap measure to accommodate .455-inch Remington bullets that reduced the relatively soft swaged lead to about .4535 inch when seated and effectively duplicated the diameter of bullets pulled from factory loads. (Hollowbase bullets pulled from pre-1970 Remington and Winchester RNFP loads measured .454 inch.)

Eventually an early version of the Lyman/Keith-type 454424 SWC mould that dropped wheelweight alloy bullets at .455+ inch was located. Since they offered a close fit for the Colt and replicas thereof with .456-inch chamber throats, they didn’t require sizing. As a temporary measure, they were set up in a Lyman lubricating tin with melted graphite-base Lyman bullet lubricant deep enough to cover the lubrication groove. When the lubricant cooled and hardened somewhat, they were cut out using the neck end of a .45-70 case with the head cut off, and bullets were driven out the opposite end, where the inside diameter was honed out to .456 inch and polished. The whole process was a bit messy, but with those Lyman 454424, .455+ inch bullets seated in a .4535-inch case neck diameter with a mild crimp, accuracy with relatively quick-burning powders like W-231, Bullseye and Unique was clearly superior to the same bullet sized to .452 inch or so and seated in a typical .449- to .450-inch inside neck diameter produced by modern carbide sizing dies that reduce bullet diameter to .451 inch or slightly less.

To illustrate how things are not always what they seem when loading cast and swaged lead bullets, size an unfired case neck in a carbide die down to about where the base of the bullet would be when fully seated. Then use the standard .449- to .450-inch neck expander to bump the inside neck diameter up with minimal bell on the case mouth, and seat a standard .451- to 452-inch jacketed bullet.

I use a Lyman .456-inch, .45-70 neck expander and a .455-inch, 230-grain Silvertip upside down with the base flush with the case mouth so it won’t be confused with a loaded round. It is important to note (1) the inside neck diameter is routinely a bit less than the diameter of the expander owing neck spring back when the expander is withdrawn.

To begin, (2) measure the outside diameter of the case neck after seating the bullet. Subtracting the known diameter of the

With a jacketed bullet seated, (3) subtract the case wall thickness from the outside neck diameter to find the diameter of the bullet. With a jacketed bullet, the calculated diameter should be the same as it was determined prior to seating. Using a cast or swaged-lead bullet, the calculated diameter will yield the amount it was reduced by seating in the somewhat undersized case neck.

Then (4) use an inertial bullet puller to knock the bullet out of the case. Measure the outside diameter of the case neck again. If measurements are taken carefully, the case neck should be the same or quite close to what it was prior to seating the bullet. This indicates the amount of elasticity of the case neck as bullets are seated and how it affects the diameter of cast or swaged-lead bullets.

Cast or swaged-lead bullets will measure from .001 to .004 inch smaller in diameter than measurements taken prior to seating, depending on the strength or hardness of the bullet alloy and the actual inside neck diameter after the expander is withdrawn during sizing (refer to 1).

With the jacketed Silvertip noted above, the first outside neck diameter measured .474 inch; with the bullet seated upside down it measured .476 inch. Subtracting the bullet diameter, .455 inch, yields an average neck wall thickness of .010 inch, i.e., 20 divided by 2.

Prior to seating a Remington .455-inch swaged lead bullet seated upside down, outside neck diameter was .474 inch; after seating it was .4745 inch. The difference, less the averaged neck wall thickness equals roughly .4535 inch, revealing the new calculated diameter of the swaged lead bullet to be .0015 inch less than the original diameter. Pull the swaged-lead bullet to reveal the new (actual) diameter after seating, which can vary slightly depending on how much numbers are rounded off in calculations and measurements.

Repeating the above with the .455-inch Remington bullet seated in an inside neck diameter of .450 inch, about standard for brass sized in post-1980s .45 Colt carbide dies, the pulled bullet measured .452 inch.

Having done all the above with Elmer Keith’s 429421 bullet cast from his alloy that was based on melted down 405-grain .45-70 bullets – tin-to-lead alloy of 1:16, BHN 8 – sized to .430 inch, as per his instructions in SIXGUNS by Keith, the bullet was seated after using a .426-inch neck expander that trued the inside measurement to .425 inch after full-length sizing in a Lyman carbide die. The bullet was pulled and found to measure .428 inch. Seating a Rim Rock .431-inch, BHN 8 cast SWC with a gas check in a .425-inch case neck, the pulled bullet measured .431 inch. From that, it is apparent that the gas check acts as a pilot in seating, minimizing or eliminating the sizing effect by tight case necks. (Note: the new Redding dual carbide die sizes the neck and case body separately.)

In reviewing all the above, the reader might be tempted to use a harder cast bullet alloy in the interest of reducing or eliminating the amount of bullet sizing that occurs during seating. That, of course, sort of flies in the face of Elmer Keith’s success, especially since his BHN 8, 429421 cast bullets were loaded without alteration over maximum loads in the .44 Special and .44 Magnum from 20,000 to 32,000 psi, respectively.

To effectively duplicate or slightly exceed the velocity of the Remington and/or Winchester factory loads with 250- or 255-grain swaged-lead bullets, respectively, order a .45-70 (.456-inch) neck expander die. The Remington RNFP bullet is available from Huntington Die Specialties and MidwayUSA in 1,000-count boxes. Powders in the burning range from Bullseye to Unique are fine, including 9.1 grains of Power Pistol, 8.0 grains of 800-X, 6.0 to 7.0 grains of Titegroup, 8.3 grains of SR-7625, 10.4 to 11.0 grains of A-5 and 7.1 to 7.5 grains of W-231 with the bullet seated to an overall loaded length of 1.65 inches. Velocities range from 825 to 910 fps, depending on barrel length. A moderate crimp is applied with standard dies, albeit the Lee Factory Crimp die or Lyman 310 seating/crimping die do the best job. Seating and crimping should be done in separate steps. Five-shot groups ranged from .75 to 1.25 inch at 25 yards when fired from a Colt New Frontier with .456-inch chamber throats and a 7.5-inch barrel.