.45 Auto Rim +P (Pet Loads)

Pet Loads for a Classic Revolver Cartridge

feature By: Brian Pearce | February, 17

The rockchuck population was excessive in 1989. They grazed in our irrigated pastures and made holes virtually everywhere, so always resting on my hip was an accurate sixgun used to thin them out at every opportunity. One day I was carrying a Smith & Wesson Model 1950 Target .45 ACP with a 61⁄2-inch barrel but stoked with .45 Auto Rim handloads, and a big chuck exposed itself at around 30 yards. The bullet struck where it was aimed, and the chuck rolled off the fence jack, a large pile of rocks used as a post. Almost instantly a second chuck appeared on the opposite side of the jack but made the mistake of hesitating before the Smith & Wesson N-frame spoke again. Another chuck appeared at around 50 yards, and once more the sixgun cracked. In the next few seconds, from a seated position, three additional chucks were taken at 83, 95 and 150 long paces.

As early as 1915, Smith & Wesson president Joseph Wesson directed his R&D staff to chamber the N-frame Hand Ejector revolver to accept .45 ACP cartridges, which was developed in conjunction with Springfield Armory. Wesson knew the U.S. was headed into war, and Colt did not have the production capacity to arm all the troops with the newly adopted Model 1911 pistol. The .45 ACP is rimless, and the Smith & Wesson ejection star could not push fired cases from the chambers. They could be hooked with a fingernail and pulled out, or pushed out with a rod or dowel from the “ball end” of the chamber, but those methods were largely impractical. To resolve that problem, a half-moon clip cut from sheet metal was devised that held three cartridges. By inserting two loaded half-moon clips, the revolver could be fired and all cartridges easily ejected with a single stroke of the ejector rod.

Shortly after the war was over, U.S. Model 1917s were sold as surplus on the civilian market, but Colt and Smith & Wesson also began offering commercial versions. While the half-moon clips worked well in military service and for rapid reloading, they were rather cumbersome for the outdoorsman and for many other applications. When the full-moon clip that held six cartridges became available, they proved to be the fastest method for reloading double-action sixguns. The clips themselves are generally difficult to load and unload without the aid of a tool (a great one being available from BMT at www.bmt equipped.com) and are often not practical for field use and general shooting.

Regardless, there was demand for a sixgun cartridge that would eject traditionally in various .45 ACP double-action revolvers. In 1920 (some sources indicate 1922), the Peters Cartridge company introduced the .45 Automatic Rimmed (aka .45 Auto Rim, .45 AR), and Winchester soon offered the same. The case was effectively a .45 ACP with a thick rim (.089 inch) to compensate for the generous headspace (or significant gap between the cylinder and the breech face) associated with these revolvers – which was required to accept the half- and full-moon clips.

The .45 AR factory loads were rather disappointing. For example, a 230-grain soft, swaged-lead bullet with a roundnose profile and hollow base was pushed to an advertised muzzle velocity of 805 fps. Pressures were limited to 15,000 CUP, which were intentionally kept low, by comparison to the .45 ACP, to prevent bullet deformation and barrel leading. Handloaders were quick to load the .45 AR with alloyed cast bullets that were of improved design, increasing the pressure to similar levels as the .45 ACP, all of which improved performance.

Due to high demand for other cartridges, Remington has not produced .45 AR ammunition in several years, but Buffalo Bore offers six loads in both “standard” and “+P” pressures, utilizing various 200-, 225- and 255-grain bullets. For reference, the standard pressure 225-grain wadcutter is advertised at 950 fps and clocked 938 fps from my 1955 Target with a 61⁄2-inch barrel, while the 255-grain FN +P, advertised at 1,000 fps, clocked 1,005 fps.

When stoked with handloads, the .45 AR is a splendid cartridge that has proven accurate while offering unusually low extreme spreads, and a broad bullet selection has made it fairly versatile, while low powder charge weights combined with the large caliber result in modest muzzle report. It has proven itself in slow fire target competitions, and although it is slightly underpowered to reliably put down the heavy 200-meter rams in IHMSA competitions, it easily displays plenty of accuracy to make reliable hits. With correct bullets, it is capable of taking deer-sized game and is well suited to light target loads that display good accuracy and mild recoil.

Since the .45 AR headspaces on the rim, bullets can be roll-crimped or taper crimped, depending on design. Since 1978, I have always had at least one sixgun chambered in .45 AR and have owned and fired several dozen revolvers. My comments here are based on practical experience, load development and much testing.

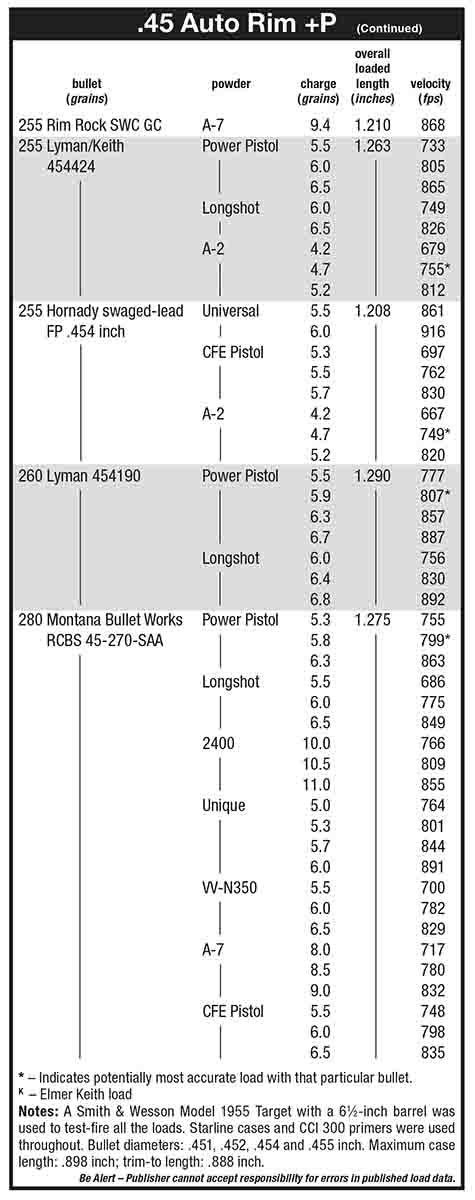

Currently the industry lists maximum overall cartridge length at 1.275 inches, but in measuring vintage cartridges from Peters, Remington and Winchester, some overall lengths were as long as 1.300 inches. Every revolver I am aware of will easily handle cartridges of this length. The longest overall loaded length used herein contained 260-grain bullets from Lyman mould 454190, crimped in the upper lube groove at 1.290 inches. It should be noted that with the .45 AR’s short powder column, it is important to seat bullets to the exact listed length, or pressures can increase significantly.

As noted, SAAMI maximum average pressures are established at 15,000 CUP, being intentionally kept low to prevent soft lead

In spite of the .45 AR having the potential to be an exceptionally accurate cartridge, not all guns shoot well. Many U.S. Model 1917 revolvers have had way too many jacketed bullets fired through their barrels and won’t hit a 55-gallon drum at 20 yards with any load. Pristine guns with minimal barrel wear are usually capable of sub-2-inch groups at 25 yards, with select loads grouping inside one inch. Most pre-World War II Colt and Smith & Wesson revolvers feature throats that measure .454 to .456 inch. Postwar revolvers have been measured that range from .451 to .458 inch, with the latter being very difficult to obtain top accuracy with. Generally speaking, guns with .451- to .454-inch throats are conducive to good accuracy and are less picky as to what bullets they will shoot well. The very rare S&W Model 1950 Target revolver used to take rockchucks featured .4515-inch throats and was exceptionally accurate. My two most recently manufactured S&W revolvers include a 625-6 Mountain Gun and a Model 625-8 with throats that measure .451 and .452 inch, respectively – typical throat sizes used on revolvers built since the middle 1980s. These revolvers generally shoot all bullets with respectable accuracy.

One problem that has plagued the .45 Auto Rim has been dies with incorrect dimensions. During the 1970s, I modified various dies to accomplish correct case sizing, bullet-to-case fit and crimp. Today those dimensional problems have long been resolved, and a new set of .45 ACP dies from RCBS, Lyman, Redding and others will work perfectly. I suggest purchasing a separate roll crimp die when using bullets designed specifically for revolvers that feature a deep crimp groove or cannelure, while the taper crimp die is recommended when using .45 ACP bullets that are void of a crimp groove or cannelure. All bullets designed for the .45 ACP and void of a cannelure were taper crimped to .470 inch, which was performed as a separate step after bullets were seated to the correct overall loaded length. For the purposes of this article, RCBS carbide dies were used, along with a roll-crimp die.

Another common Auto Rim problem has been premature case splitting. In the 1970s, when I first began handloading this cartridge, occasional splitting when firing factory ammunition was not uncommon, but upon reloading those cases and firing them a second time, 15 to 20 percent would split. A variety of things were tried to help extend case life, but today I simply purchase Starline cases, available factory direct at 1-800-280-6660. They are stronger and considerably more durable.

While the .45 AR can be loaded with a variety of bullet profiles, some designs that work well in .45 ACP autoloading pistols might not produce great accuracy in revolvers. For example, the old 230-grain FMJ “Ball” roundnose in military profile has a notably shorter bearing surface than many JHP designs of the same weight. In revolvers with .454- to .458-inch throat diameters, these bullets can tilt substantially as they pass through the throats, resulting in poor accuracy. Most 230-grain JHPs feature a much longer bearing surface, which minimizes tilting and generally produces greater accuracy.

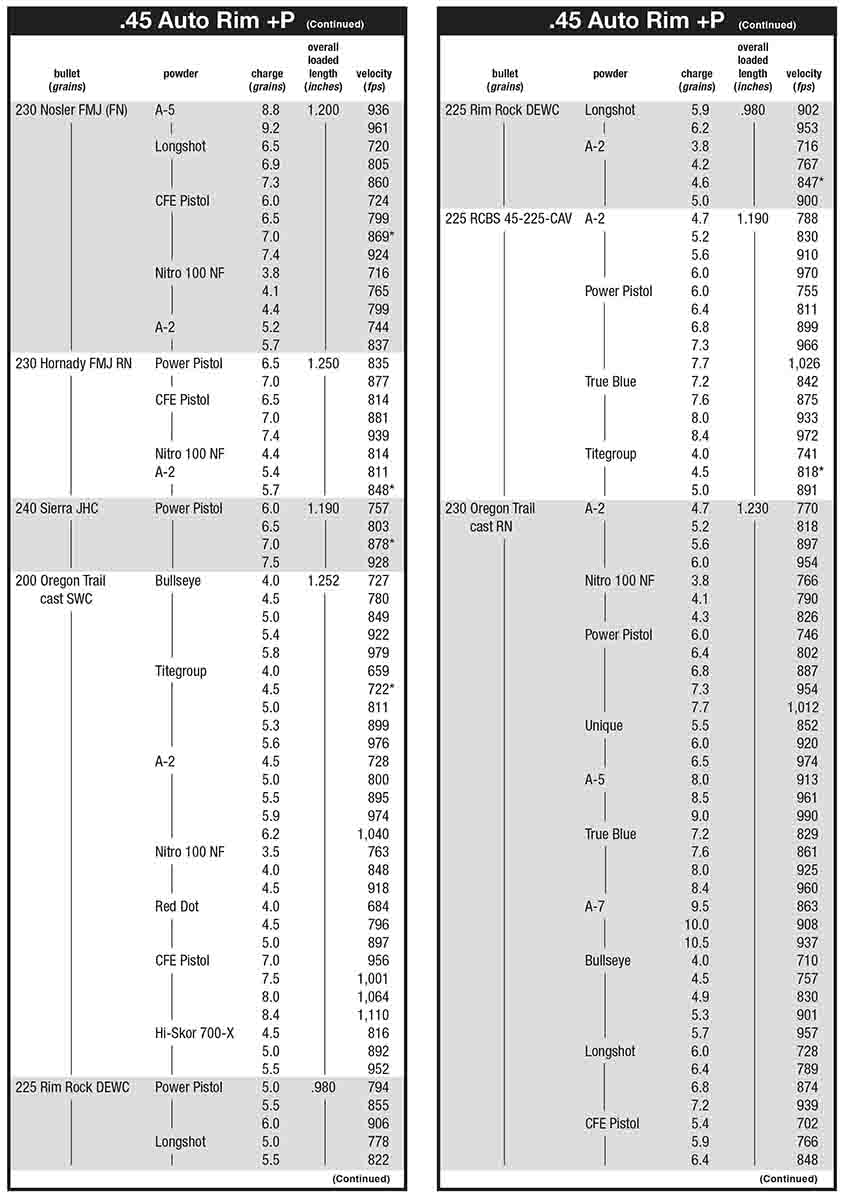

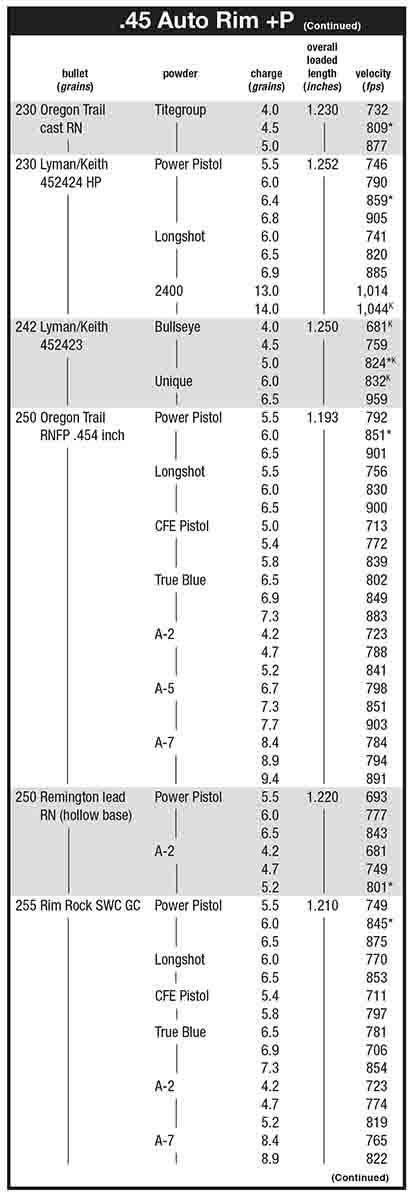

It is preferred to size cast bullets as close to throat diameter as is feasible, which also prevents tilting and minimizes bullet deformation. Some of the best accuracy obtained with the Model 1955 Target, with its .454-inch throat diameter, was with bullets that measured .454 to .455 inch. For revolvers with larger throats, consider using hollowbase cast bullets with a Brinell hardness number (BHN) of not over 8 to 9, or swaged-lead hollowbase bullets from Remington (designed for the .45 Colt) that will obturate to fill the throats, which serves to keep the bullets from tilting and aids in obtaining the important gas seal. Outstanding accuracy has been achieved with many cast bullets that weigh 250 to 280 grains, which can obturate and offer a comparatively long bearing surface. Although velocity is usually limited to around 850 to 900 fps, these loads more or less duplicate .45 Colt ballistics.

Casual target shooters will enjoy various 200- to 230-grain cast bullets pushed to around 700 to 800 fps, which offer minimal barrel wear and long life. Accuracy can be outstanding.

The Rim Rock 225-grain DEWC bullet offers a large, full-caliber flatnose that provides considerable shock typical of the wadcutter design. This is not a long-range bullet but delivers unique performance at 900 to 950 fps and has become very popular in .45 Colt defense loads. Oregon Trail offers a 250-grain RNFP sized to .454 inch that produced several 25-yard groups that hovered between one to 11⁄2 inches using 6.0 grains of Alliant Power Pistol or 5.8 grains of Hodgdon CFE Pistol powder for around 850 fps. Bullets from Lyman mould 454190 (sized to .454 inch) and weighing 260 grains gave excellent accuracy when pushed 900 fps using Power Pistol powder. For a heavyweight bullet, the 280-grain SWC Keith-style bullet from RCBS mould 45-270-SAA (available from www.montanabulletworks.com) is an excellent choice for deer and general use. Try 6.0 grains of Power Pistol or 6.2 grains of Hodgdon CFE Pistol for around 825 fps and top-notch accuracy.

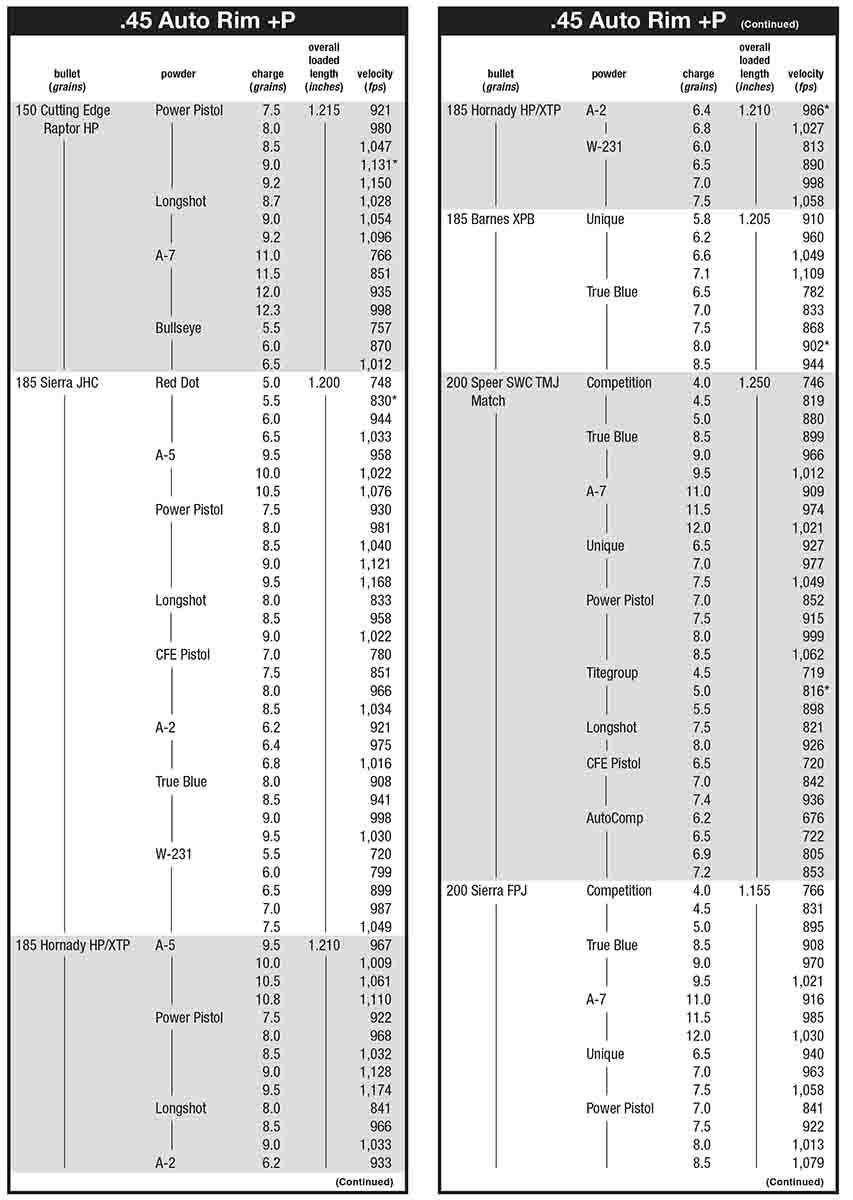

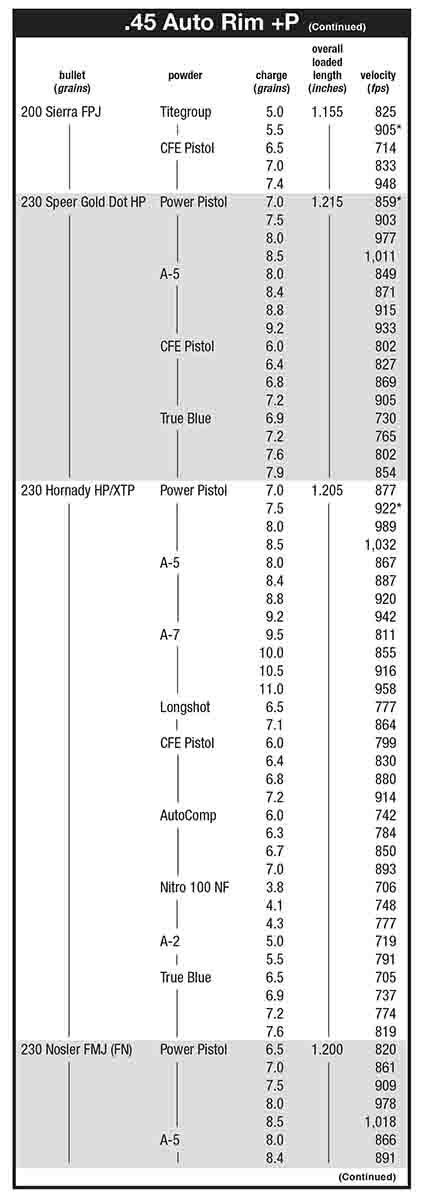

Jacketed bullet selection is huge with designs for about any application. The 185- and 200-grain match and JHP designs can deliver excellent accuracy at velocities as low as 700 fps or as high as 1,200 fps. Various 230-grain bullets are widely popular with excellent choices including the Hornady HP/XTP, Speer Gold Dot HP and Nosler FMJ FN and HP. The heaviest jacketed hollowpoint bullet used here was the Sierra 240-grain JHC, designed specifically for revolvers and reached over 900 fps using Power Pistol powder. A very interesting bullet, the lightest tested, was the Cutting Edge 150-grain Raptor HP. It features a very large hollowpoint to assure reliable expansion, even at lower velocities. Accuracy was excellent and velocities reached 1,150 fps with select loads.

For light target loads, Accurate No. 2, Hodgdon Titegroup, Alliant Red Dot, Bullseye and Power Pistol gave excellent results. For higher velocity loads and those containing heavyweight bullets, notable results were obtained with Power Pistol, Unique, Ramshot True Blue, Hodgdon Longshot, CFE Pistol and Accurate Nos. 2 and 5.