Propellant Profiles

Alliant Reloader 16

column By: R.H. VanDenburg, Jr. | February, 17

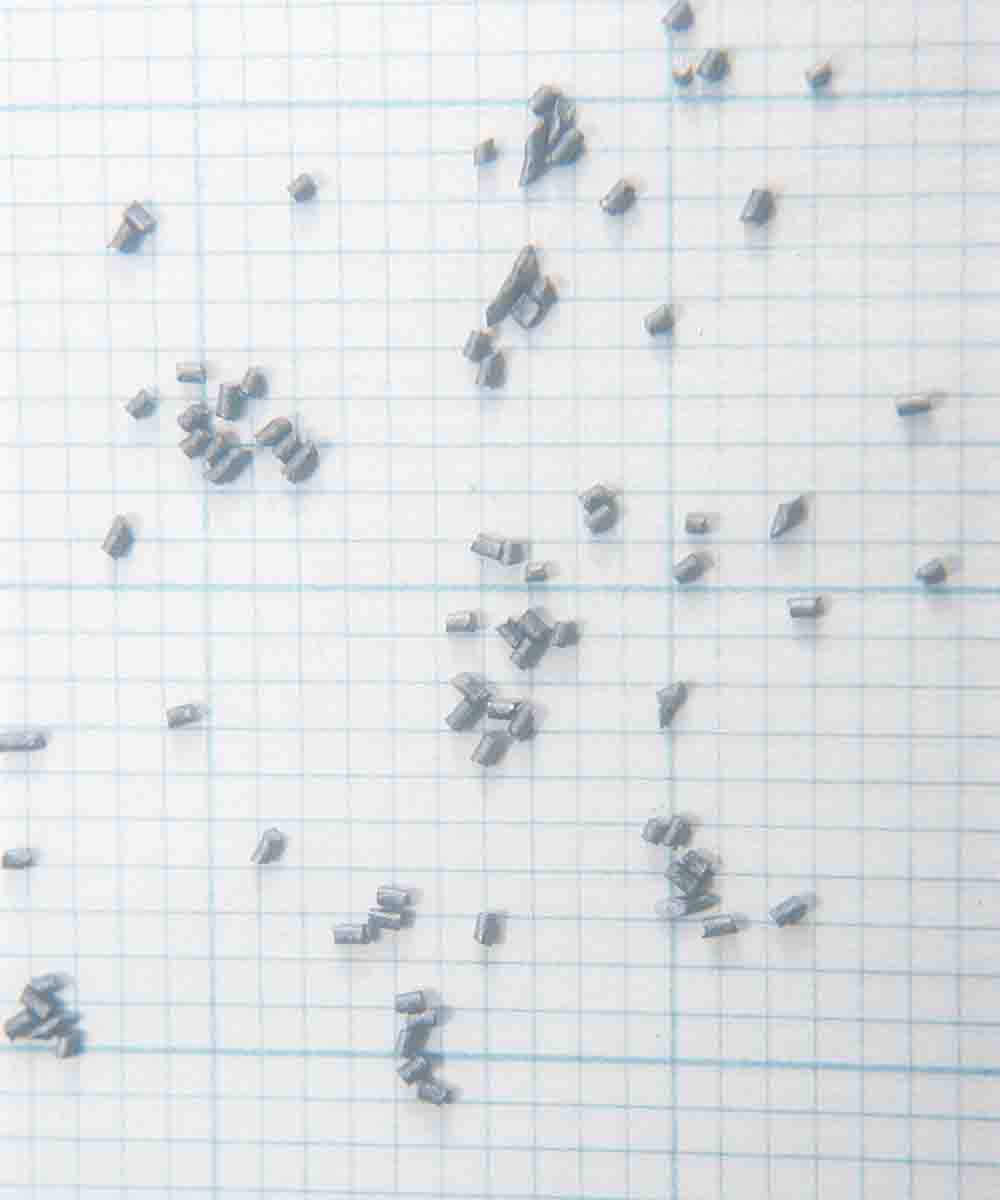

Reloder 16 is a double-base extruded powder with a single perforation. Nitroglycerin content is 6.8 percent. Dimensionally, powder kernels nominally have a length of .059 inch and a diameter of .039 inch. Its bulk density is .890g/cc. According to Alliant literature, the burning rate sequence of similar Alliant powders, from fastest to slowest, is RL-15, RL-16, Power Pro 2000-MR and RL-17. Reloder 16’s principal use is “medium rifle loads” with a secondary use for “short magnum loads.” It is available in one- and five-pound canisters.

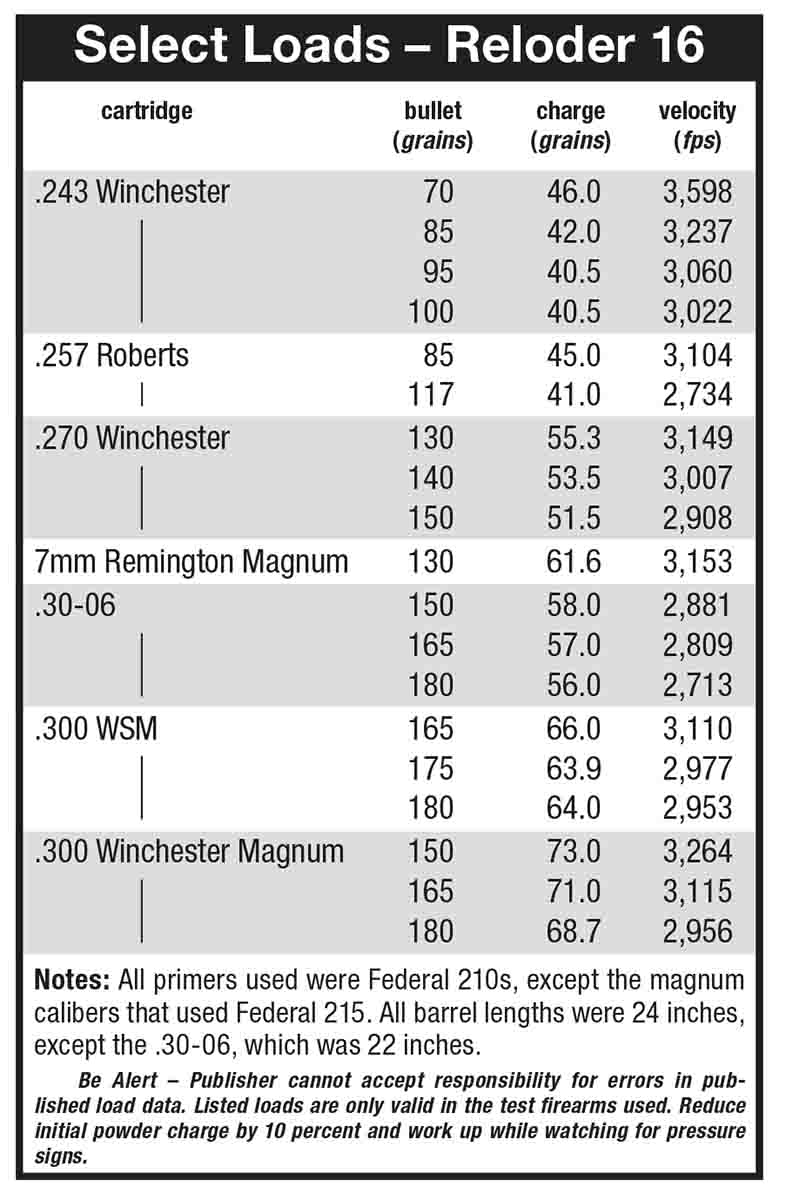

In reviewing Alliant’s published load data, I found a range of cartridges from the .243 Winchester to the .300 Winchester Magnum. In general, Reloder 16 acquitted itself very well in Alliant’s test barrels. In

my tests, across the board, Alliant’s published velocities were never matched. Of course, precision-chambered test barrels, even of the same length, are expected to outperform factory barrels, and they did. Published velocities are also generally the average of several powder lots, and my lot of Reloder 16 may well have been on the slow side. Frankly, this means little to me, as I found accuracy to be very good, often producing sub-inch groups from barrels not accustomed to such performance. Also noted was that, with exceptions, all Reloder 16 maximum loads were compressed. I’m not a great fan of heavily compressed loads, even when professional ballistician friends assure me it’s “okay,” so I was careful to dribble powder charges into cases to mitigate things as much as possible.

Time and weather permitted wringing out the powder with a wide range of cartridges and bullets. I started with the .243 Winchester and selected bullet weights of 70, 85, 95 and 100 grains from Nosler, Speer, Berger and Sierra, respectively. All performed well, especially the Berger 95-grain VLD. Bullets of 85 grains are usually my choice for varmints, and I’ve had numerous one-shot kills on deer and antelope with several 95-grain bullets.

When a company introduces a new powder, it usually tries to incorporate as many popular cartridges as it can in its initial load data release. This often leaves other entirely appropriate cartridges for future development. As the .257 Roberts was not among Alliant’s cartridge list, I added it, using Nosler 85-grain Ballistic Tips and Hornady 117-grain SST bullets as a big-game choice. Alliant literature encourages reloaders to begin with a starting load equal to the maximum published load for a given bullet but reduced by 10 percent. Reasoning that a Reloder 17 starting load would be a good place to start when testing Reloder 16, that was my approach. I increased powder charges one grain at a time until I came within a grain of the Reloder 17 maximum and, in doing so, found a couple of very impressive loads. The Nosler Ballistic Tip with 45 grains of RL-16 snugged bullets into a five-shot group of .650 inch. A 41.0-grain load with the Hornady 117-grain SST did almost as well at .975 inch. As the saying goes, they’ll do.

The 7mm Remington Magnum is paired with Reloder 16 only with light bullets in the 110- to 130-grain range. Of note is that these loads were not compressed and, as with all the magnum cartridges, magnum strength primers are called for. I restricted my tests to a 130-grain Speer, as I didn’t have any of the lighter bullets on hand and question their use at that.

I was back on happier ground with the .30-06 and opted for a Hornady 150 grain, a Speer 165 and a Sierra 180. All performed very well, and I would select any of the three depending on the game. My Remington Model 700 has a 22-inch barrel, so velocities were quite a bit under Alliant’s published speeds developed with its 24-inch tube, but I’ll take my actual results any day.

Next up was the .300 Winchester Short Magnum. Alliant listed data for bullet weights from 150 to 185 grains, including, I noted, the Sierra 175-grain MatchKing. I had some of these bullets on hand so included them in the tests, along with a 165-grain Speer and a 180- grain Nosler, all with magnum strength primers, of course. My Winchester Model 70 Featherweight .300 WSM is a good performer, and Reloder 16 worked well. Best groups were produced with the MatchKing, but that should be no surprise; still, both of the hunting bullets more than held their own.

Last up was the .300 Winchester Magnum. With magnum strength primers firmly seated, I chose a 150-grain TSX from Barnes, a 165-grain GameKing from Sierra and a 180-grain Partition from Nosler. Noteworthy, the Nosler 180 was not a compressed load. Performance, as expected, was good throughout.

On reflection, I was quite pleased with Reloder 16. New chemistry along with a de-coppering agent are all steps in the right direction. Shot-to-shot consistency in the form of very low extreme spreads was uniformly excellent throughout the tests. I don’t know what else to ask for.