In Range

In Search of Precision

column By: Terry Wieland | November, 22

This type includes fitted turnscrews, bullet moulds, nipple wrenches and so on. Find some with the name Purdey or Boss engraved on the shaft and they’ll go for big bucks.

In America, pretty much anything with Harry Pope’s name on it, usually bullet moulds, but other tools as well, will command a hefty premium. About 20 years ago, as the renewed interest in Schützen competition was just taking off, a Pope bullet mould for his special .33-caliber brought about $650 on eBay, when a comparable Ideal mould for a .32 would have sold for $75.

At various times, I’ve seen loading presses offered for sale on the “make an offer” table at gun clubs, usually with an assortment of dies, odd accoutrements and batches of random components. These either come from the estates of deceased handloaders or, less commonly, from handloaders who have upgraded their equipment. I say “less commonly” because most of us who have been in the game for a while fall into a habit of never throwing anything away even if it’s old, obsolete, or for a caliber we no longer own and expect never to own again. We just never know. Which is why, last time I counted, I had die sets, and many of them duplicates, for about 90 different calibers. I also have four shotshell presses with fittings for every gauge. As for metallic-cartridge presses, at last count, there were four.

One of these takes first prize in the “specialized use” category. It’s an ancient Hollywood Junior press set up to do exactly one thing – impress a pie-crust crimp on 20-gauge brass shotshells loaded with ball for my one and only E.M. Reilly 20-gauge hammer double, originally intended for the express purpose of repelling boarders on the China Sea. At least, that’s my theory. This gun, affectionately known as the “little thug,” began life as a .577 Snider double rifle, with 24-inch barrels. At some point, for whatever reason, the barrels were bored out to 20 gauge, but it still feels and handles like a rifle, so I treat it as such.

My late friend, Bob Hayley, cast some round ball and pointed slugs for it and then made a crimping die. Because of the size of the case, the die is 1.5 inches in diameter, which calls for an oversized press. Down in one of his rattlesnake infested out-buildings, we found a Hollywood Junior that accepted such dies. I crossed his palm with silver, cleaned it up, and it now stands ready at any moment to replenish my stock of 20-gauge pirate repellant and that’s all it does.

I mention all this as an introduction to the old Hollywood line of reloading tools. Hard to believe as it may be, in the 1950s there were many ground-breaking manufacturers of reloading tools based in California, and the Hollywood Gun Shop was one of them. It was situated on Hollywood Boulevard, in Hollywood, California. Believe it or not.

The Hollywood Junior has three round steel bars arranged in a triangle, connecting the base and the top plate. The central block of the press slides up and down inside the triangle, carrying the cartridge case, while the die is fixed in the top plate.

More famous, however, is the Hollywood Senior. This has a base and top plate with one massive shaft 2.5 inches in diameter. The shellholder is fixed in a steel collar that rides up and down on this shaft, while the die is positioned in the stationary upper housing.

This was not a new concept; other manufacturers of loading equipment, notably Potter and Universal, had used similar systems, but Hollywood’s was massive. In its steel-shaft configuration, it weighed 40 pounds. The 1963 Gun Digest review of new loading equipment described it as “precision made in every respect, beautifully machined in virtually every part…” The combination of mass, precision, and finely machined surfaces made for a tool that was a pleasure to use.

English shotgun writer G.T. Garwood coined the word “eumatic” to describe this quality, and it applies not just to shotguns and other firearms, but to any mechanical device, including any and all reloading tools.

About the same time Hollywood was in business, up the road in Oroville, California, Fred Huntington Sr. founded the company that became known as RCBS (for Rock Chuck Bullet Swage). He expanded from bullet swages into loading dies, presses and every other conceivable loading tool. Eventually, he sold the company, although his two sons, Fred and Buzz, retained the retail outlet, now known as Huntington Die Specialties. For years, Huntington’s had a special relationship with RCBS, and if you had an ‘in’ with Fred, you could get custom dies more quickly.

RCBS is now part of Vista Outdoors, the large conglomerate anchored by Federal Ammunition. RCBS has pioneered many different types of loading tools; some worked out, some didn’t, some evolved, some were abandoned. Its Rockchucker loading press has been a mainstay, and RCBS dies are among the best a handloader can get.

Broadly speaking, through the 1950s and into the 1960s, manufacturers emphasized quality and durability, assuming their tools should last a lifetime. From the 1970s onward, price became the major consideration, and many tools became, for lack of a better term, disposable. This trend was true of many things. Go back and pick up a Schoffstall Universal Priming Tool from the old days, and you’ll see what I mean. It’s a solid, precision instrument, and a joy to use, unlike the majority of priming tools one finds today.

In recent years, however, the interest in ultra-long-range shooting has created a demand for precision loading tools, including highly specialized dies for creating the most uniform and consistent handloaded cartridges.

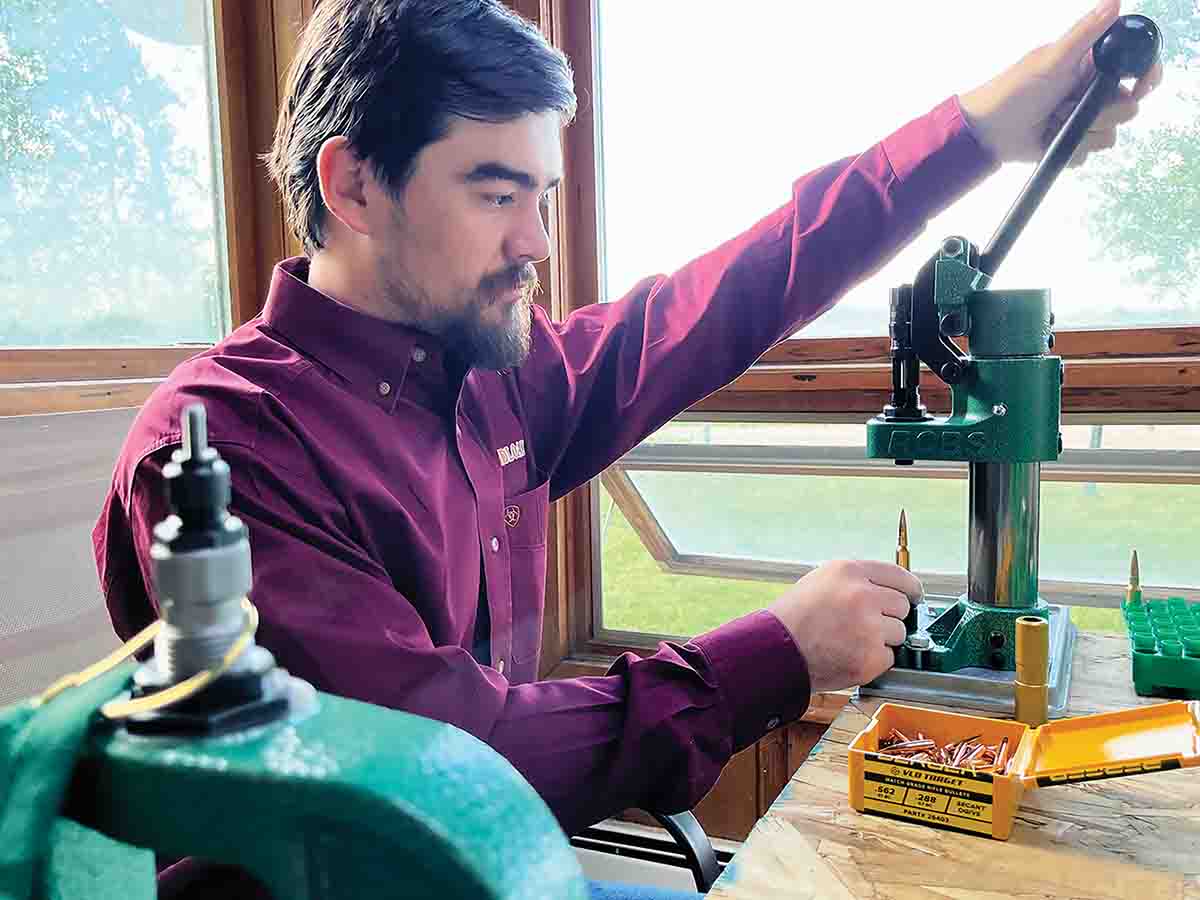

In its newest loading press, the Summit, RCBS cast back to the 1950s, adopting the venerable design of the Hollywood Senior, and building a precision unit around a central pillar. In the Summit Press, the cartridge case is stationary in the base, while the collar that moves up and down carries the loading die.

In July, a group of us were invited to Wyoming to attend a seminar sponsored by RCBS and its Vista sister company, Bushnell Optics. RCBS set up four complete loading stations where we could create our own precision, long-range 6.5 Creedmoor ammunition, then shoot it to see how it stacked up against factory match stuff.

This was the first chance I had to try the Summit Press, as well as some other new RCBS products, like the Matchmaster powder measure/scale, and the case-conditioning unit. (For the record, I found the Matchmaster a tad temperamental for my taste, and the conditioning unit inexplicably omitted a tool for uniforming flash holes, which I consider essential no matter how good you think your brass is. But I digress.)

The Summit Press left me with the feeling that, well, I had to have one. Partly, this was due to the fact that I’ve wanted a Hollywood Senior ever since I saw a picture of one in an early Gun Digest, and the last one I saw for sale, the guy wanted to start the bidding at $600. I don’t want one that much. But the Summit Press will fasten to my RCBS base plate, which is already permanently attached to one of my bench inserts, so it will fit seamlessly into my loading operations.

This will combine “eumatic” euphoria with practical application and if any modern loading press is going to become a collector’s item, it’s this one.