Mike’s array of World War II 9mms: (1) Belgian FN Hi-Power, (2) German P08 Luger, (3) Canadian Inglis Hi-Power and (4) a German P38.

Without a doubt, I think 9mm Parabellum pistols are currently the hottest sellers in the American handgun market. Second; I have no doubt that the great majority of 9mm Parabellum handloads assembled nowadays are intended for pistols of relatively new manufacture. Third; I am of the mind that most of today’s 9mm handloads carry jacketed bullets with the majority being of hollowpoint construction. Fourth: I think most currently handloaded 9mms are fairly hot regarding pressures and velocity to ensure jacketed hollowpoint (JHP) bullet expansion.

My 9mm Parabellum handloading efforts are in the opposite direction. Why would anyone want mild 9mm ammunition? Four of my 9mm pistols date from the World War II years. One is a 1938 vintage German P08 Luger. Two are Hi-Powers (aka P35s). One of the Hi-Powers was made by the John Inglis Company of Canada and the other by Fabrique Nationale (FN) in Belgium. Both date from 1944. The fourth one is a German P38 dating from 1943.

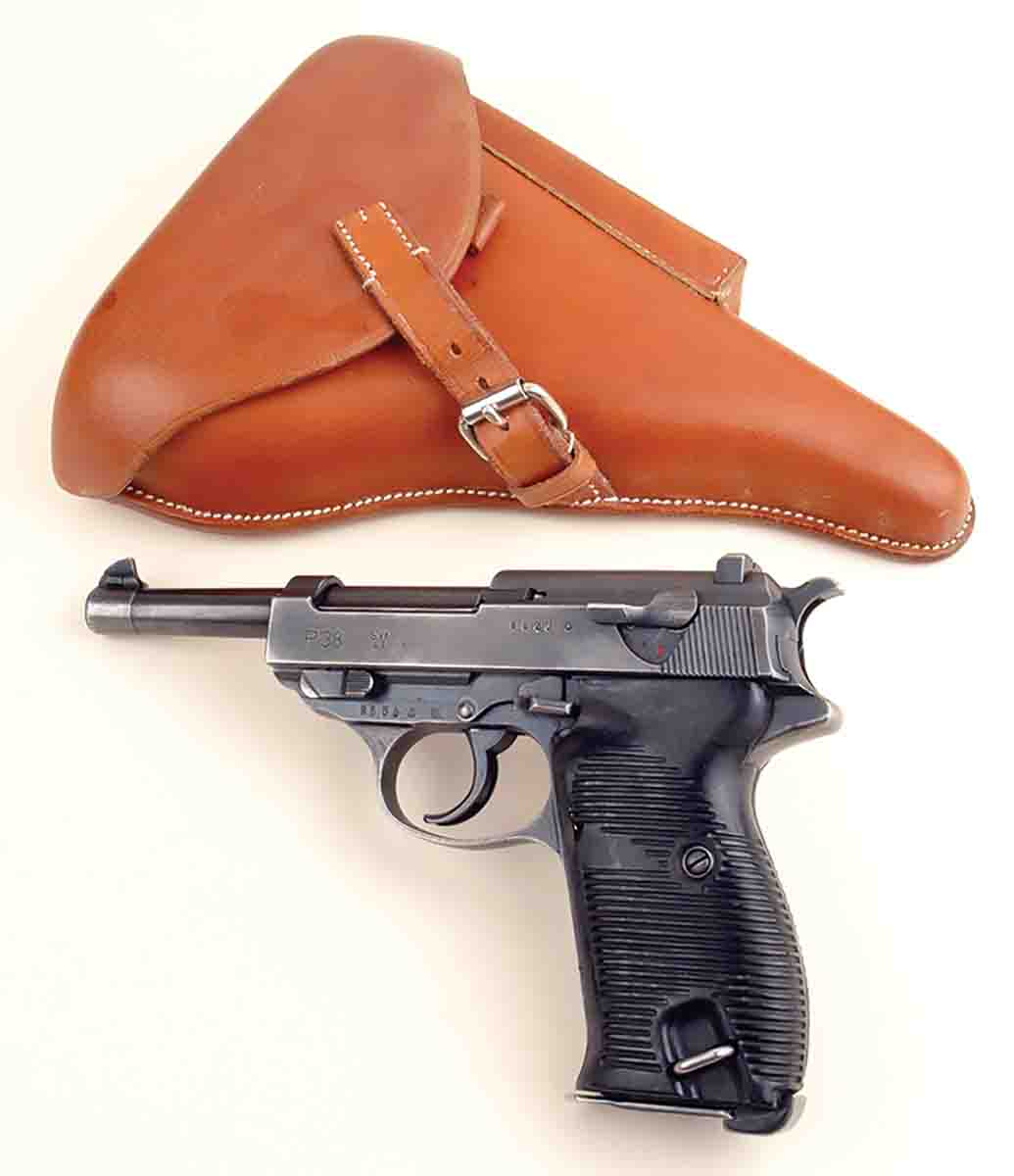

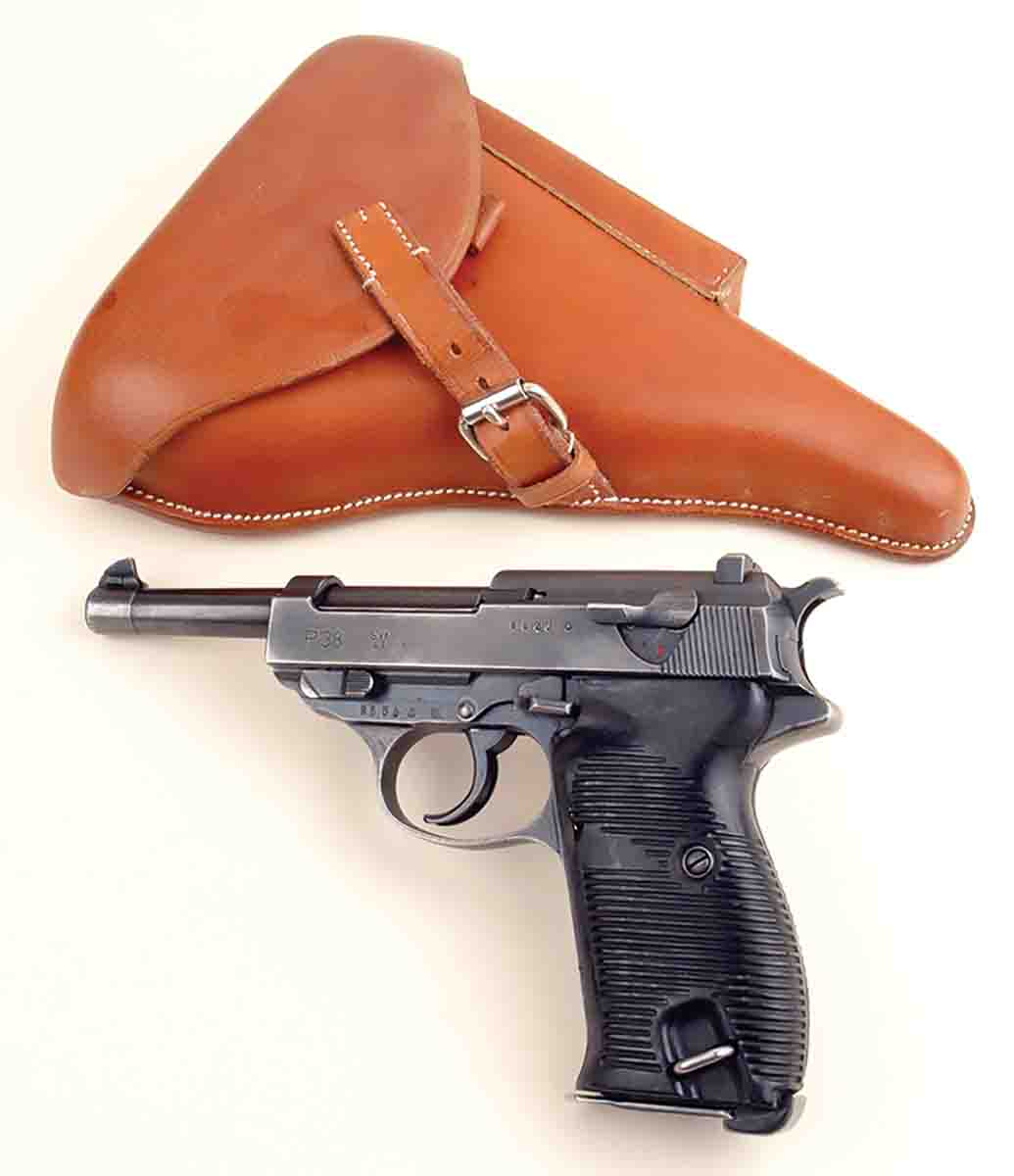

German P38. Note the double-action trigger.

These pistols are all collectibles, meaning their value ranges are considerably higher than the average modern 9mm semiauto. I want not, nor need hot 9mm handloads or JHP bullets. In fact, my Luger is so finicky about ammunition that feeding with most modern JHP factory loads is problematic. What I do want for these World War II 9mm semiautos is ammunition that functions reliably, gives reasonable accuracy and wears them minimally. Furthermore, I want a handload combination that does all those things in all four pistols. Hence, my reason for loading the hundreds of rounds for this article and test firing them over a period of months in all four of my World War II vintage 9mms.

German P08 Luger. Note the dovetailed front sight.

Let’s start with a little 9mm military history. In 1900 came the 7.65mm (.30) Luger cartridge with its bottlenecked cases carrying 93-grain, .308-inch full metal jacket (FMJ) bullets. By 1902, designers using that case head straightened the body – more or less. It actually tapers .011 inch from rim to mouth in its .754-inch length. The new case accepted bullets of .354/.355 inches in diameter (aka 9mm). The name given to the new round was 9mm Parabellum, which is Latin literally meaning “to prepare for war.” Americans seem more likely to refer to it as 9mm Luger as I will do from here on. Trying to pin down the exact military ballistics of 9mm Luger is nigh on impossible because the cartridge has been used and is still being used by military organizations literally around the world. Some sources list 115-grain FMJ bullets at 1,250 feet per second (fps), some say 124-grain FMJs at the same speed and others rate velocity at 1,300 fps with 115-grain FMJs.

By 1904, the German Navy adopted “Luger” pistols with 6-inch barrels chambered for the new round. They were named Pistole 1904/P04. With a few design changes, it became Pistole 1906/P06. The German Army dithered for two more years before finally accepting the Luger design as Pistole 1908/P08 with a 4-inch barrel. The Luger’s history is fascinating in that there never was a “Luger factory.” They were made in facilities all over Europe. In fact, between the world wars, some Lugers were even assembled by the English company of Vickers from parts shipped over from the continent. My World War II Luger was made in 1938 and wears the code S42 meaning it was made at Mauser Werkes at Orberndorf.

The Canadian Inglis Hi-Power was made for the Chinese Government with an original wooden holster/stock.

Interestingly, so was my World War II Pistole 1938/P38 from 1943, although by that time, Mauser Werke’s code was “byf.” The P38 was designed by Walther engineers and although made in several facilities there were never enough to completely displace the Luger in Wehrmacht service. Some pistol historians rate the P38 as the first “modern” military handgun because it was double action, at least for the first shot. P38s had 5-inch barrels and exposed hammers.

My third World War II 9mm was made in Belgium by FN and was of course, simply the Browning Hi-Power aka P35. Germany occupied Belgium in 1940 and kept the FN factory hard at work. Hi-Powers going to Germany’s armed forces were designated 640(b) My FN bears a tiny code of WaA140.

Number four of my World War II 9mms can be lumped in with the FN Hi-Power for it is also a Hi-Power, but made by the John Inglis Company in Canada. As the story goes, during the war, some FN Hi-Powers were smuggled out of Belgium and the John Inglis Company reverse-engineered them. Many were delivered to Great Britain for its commandos and paratroopers and thousands were ordered by China. The Chinese liked the wooden holster/shoulder stock concept and also wanted the tangent rear sight graduated to a ridiculous 500 meters. Both FN and Inglis Hi-Powers have 4.63-inch barrels and a 13-round magazine capacity. My Inglis was intended for the Chinese complete with a shoulder stock.

Mike used Lyman’s new stainless steel Pro-Die 9mm set for all reloading for this article. The set includes a taper-crimp die.

At this point, some idea should be given for the purposes of my light 9mm handloads. They are NOT intended for self-defense. They are not going to be fired at animals – large or small. My only reason for developing this type of 9mm load is for plinking, i.e. my own recreation and mostly at steel targets. At this point in my life, if the word well is running dry, I take an afternoon and mostly spend it in plinking at reactive steel targets with paddles. These targets measure between 3 and 5 inches and are placed at 20 to 25 yards. From my shooting house, I can sit and plink away without having to ever reset targets and the relaxation replenishes my word well. Therefore, pinpoint accuracy is welcome but are not overly great concerns.

With the limited volume of the 9mm Luger’s .754-inch case faster- burning pistol powders are most applicable; meaning those in burning rate from Bullseye and Titegroup on the fast side to Power Pistol and HS-6 at the slower end. While there are plenty of powders to choose from in the Lyman Cast Bullet Handbook 4th Edition, I picked Bullseye, Titegroup and W-231. Admittedly, my propellant selections are influenced by the fact those mentioned are favorites in several other handgun cartridges, consequently a large supply of each is on hand.

Note the difference in front sight mounting of Inglis and FN Hi-Powers. The Inglis (left) has a dovetailed front sight. The FN (right) has a staked in front sight.

That brings us to bullets. From its inception to this day, military 9mm Luger ammunition has been loaded predominately with FMJ roundnose bullets. Some early German military 9mm loads had truncated cone (TC) FMJ bullets. For this project, five types were tried: two cast by myself, one lubricated commercially cast bullet, one cast bullet of the coated variety and one FMJ factory bullet. In the same order they specifically were: 120-grain roundnoses from Lyman mould No. 356242, 135-grain TCs from MP Molds’ 357-135FB, Oregon Trail’s 145-grain roundnose, Cheyenne Bullet Company’s coated 124-grain TC and Montana Gold’s 125-grain roundnose FMJs. Again, in the same order, bullet diameters were .357, .357 .356, .356 and .354 inch. Actually, the Lyman bullets measured just a touch under .357 inch but were sized in a .357-inch lube/sizing die. Lyman nominally lists that particular bullet as .356 inch, but I was able to get them dropping from the mould larger by using straight Linotype alloy as was also used with the MP Molds’ bullet.

(I would like to mention that the Cheyenne Bullet Company 9mm used herein could best be described as a hybrid. It has the rapidly sloping nose of a truncated cone but ends with a rounded tip.)

See the markings on the Belgian Hi-Power. If you look closely right over the trigger the German Waffenampt is visible.

As for brass, because I have two 9mm World War II submachine guns there was also a tub full of once-fired brass to choose from. For this project, enough Federal commercial brass was sorted out for all bullets. They were combined with Winchester Small Pistol primers. New Lyman Pro Load dies assembled everything to satisfaction including taper crimping bullets.

Overall, in my lifetime of cast bullet shooting, I’ve been able to report success. I’ve gotten cast bullets to shoot reasonably accurately with better than 90 percent reliability from a Ruger Mini-14 223 Remington. On the other end of the caliber spectrum, I’ve gotten 1½-MOA 10-shot cast bullet groups from 45-70s at 300 yards with black powder for propellant. Revolvers are just about no-brainers. Just fit bullet size and temper to revolver barrel and cylinder dimensions and intended velocity and all will be well. Some of the most accurate cast shooting I’ve done with a semiauto from my Ransom Pistol Machine Rest was with a Kimber 1911 40 S&W. Many groups with it fired at 25 yards were ragged holes.

Markings are shown on the side of the Inglis Hi-Power. Note that they credited it to Browning and FN.

Where I have been ALMOST a cast bullet failure has been with 9mm Luger. Back in the 1970s, my very first cast bullet 9mm Luger results were not bad from an accuracy standpoint, but were less successful concerning safety. Here’s the story. Having only enough cash for the S&W Model 39 and a set of reloading dies, I figured to carefully load 150-grain, cast semiwadcutters (SWC) over 3 grains of Bullseye. After all, my

Lyman Reloading Handbook 45th Edition listed a 158-grain cast bullet for 9mm Luger with that powder charge. Where Lyman’s book and I differed was that they used a roundnose bullet and mine were SWC.

Initially, all went well. In fact, I was delighted to hit most things aimed at out to about 25 yards and likewise joyful that functioning was perfect. The brand of the dies purchased is not remembered but they did not taper crimp. I knew 9mm Luger headspace on the case mouth so my technique was to roll crimp cases slightly just to remove the bell. All was well for a couple of hundred rounds. Then evidently, a sharp shoulder on an SWC caught something, which pushed it back into the case during its voyage from magazine to chamber. When fired, the case wall blew out, stinging my hand and splitting both grip panels. Luckily, nothing else was harmed.

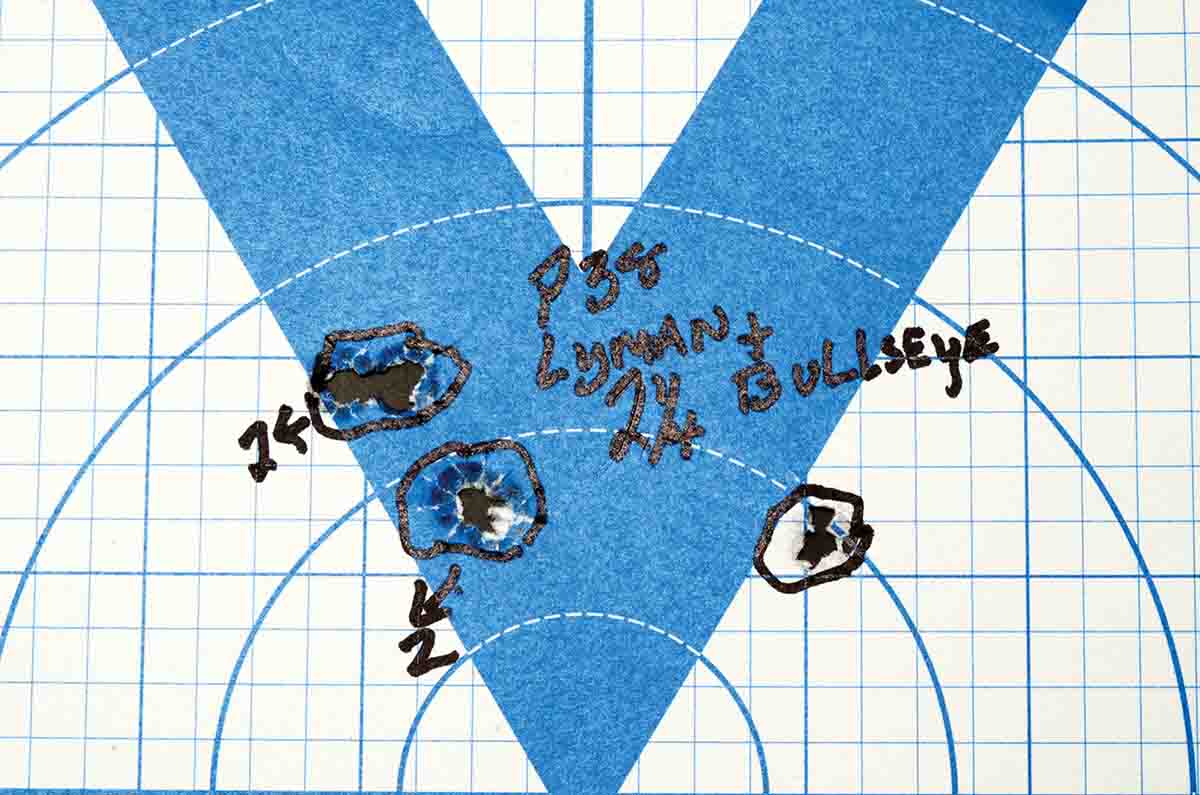

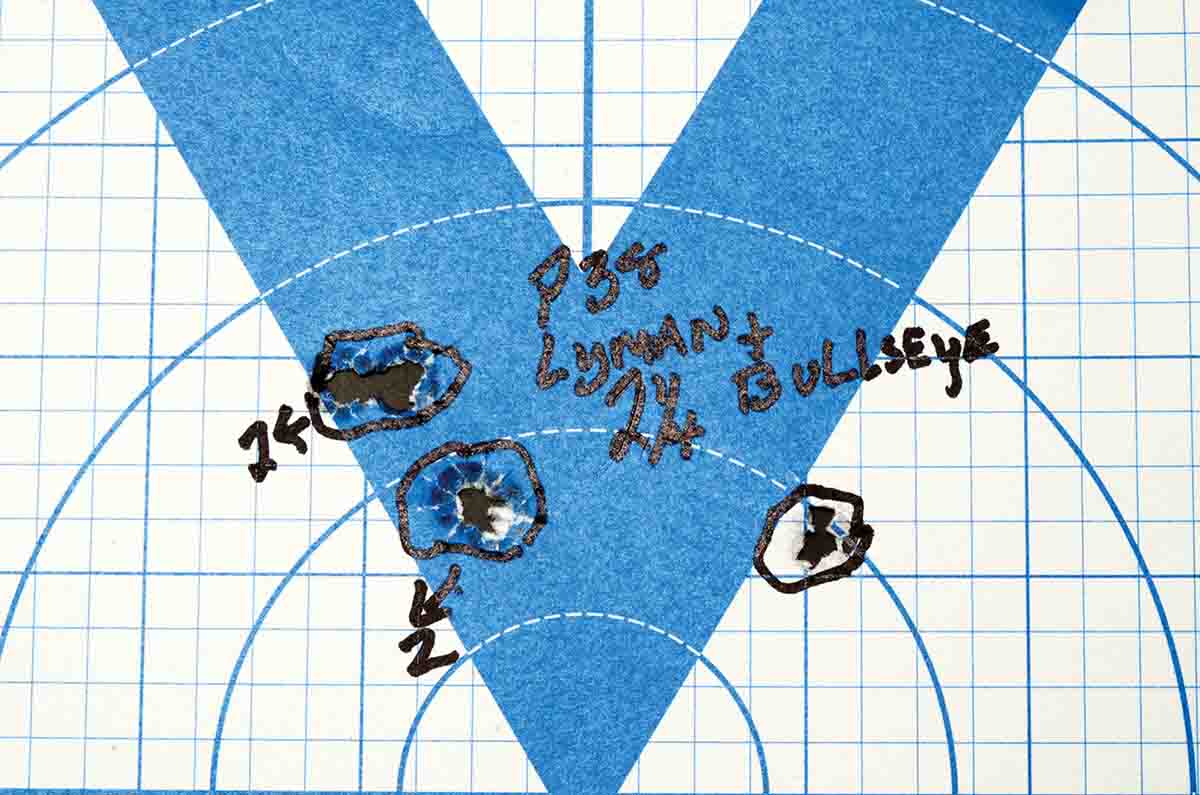

This is one of the best groups obtained from the P38.

On and off over the years, I returned to 9mm Luger reloading. Results were often good with jacketed bullets but usually cast bullet results were disappointing. Sometimes bullets simply tumbled, sometimes they were on point and just once in a while, a decent five-shot group formed. One gun writer offered me the opinion that the problem was with most 9mm Luger pistol’s 1:10 twist. That didn’t make sense to me, for I had fired in several .30-caliber rifles plenty of 75- to 85-grain cast bullets meant for 32 Autos. Those rifles also with 1:10 twists delivered fine groups at 25 yards.

In my cast bullet experiences, a sure cause of tumbling bullets has been ones that are undersize for a barrel’s groove diameter. I’ve written many times that my preference would be cast bullets even as much as .003 inch oversize instead of .001 inch undersize. With that thought in mind, I’ve experimented with larger bullets than the usually recommended .355-inch diameter, hence the use of .356 inch commercially cast Oregon Trail’s and Cheyenne Cast Bullet’s 9mms of .356-inch diameter. That’s also the reason for essentially using the Lyman 120-grain roundnose as cast, just running them through a .357-inch lube sizing die only for lubricant application.

The bullets Mike handloaded for this article are: (1) Cheyenne Bullet Company 125-grain TC coated cast bullet, (2) Lyman 120-grain cast RN mould No. 356242, (3) MP Molds 135-grain cast TC No. 357-135FB, (4) Montana Bullet Company 124-grain FMJ and (5) Oregon Bullet Company 145-grain cast RN.

A relatively new experience for me has been in loading Oregon Trails’ 145-grain roundnose and the 135-grain truncated cone design from MP Molds. Results with these two heavier 9mms fit my purposes perfectly. Velocities from all three propellants were in the 900 fps range, yet functioning was better in the Luger. From the cursory accuracy testing they seemed to group best of in all four 9mms. There were a couple of stoppages with the Luger in the test-firing but not a single one with the other three pistols. The MP Molds 357-135FB mold is an eight cavity so turning out a year’s worth of plinking bullets with it would be a casual afternoon’s casting session.

Now I’d like to discuss this matter of group shooting. For my Ransom Rest I only had grip adapters for the P38. A few groups of five shots each at 25 yards were fired with decent results, then things went downhill. Bullets were flying everywhere. Searching for the problem revealed that the two-inch-thick, piece of “bridge plank” to which the rest was bolted, had split completely after 22 years of use. Afterward, I satisfied my curiosity by shooting three-round groups. The two heavier 9mm put bullets inside about 3 inches. Bullseye seemed to give the best results in accuracy and functioning overall.

Mike shooting steel with the Inglis Hi-Power with the shoulder stock mounted.

Here’s where I stand after shooting these several hundred rounds of handloads. My “light” 9mms will use either Oregon Trail’s 145-grain roundnose or my own 135-grain TCs from the MP Molds. Lyman’s 120-grain cast roundnose can’t be discounted; its only drawback for me is the mould is double cavity. The FMJ bullets will be reserved for my two subguns; both of which lead foul terribly with cast bullets.

Mike shooting steel with the German Luger.

.jpg)

.jpg)