Reloader's Press

Cast Bullets

column By: Dave Scovill | June, 20

The late Ken Waters rarely did a “Pet Loads” for rifles or handguns that didn’t include a generous selection of cast bullet loads. Even Wolfe Publishing handgun editor John Zemanek, who traveled the world as a handgun competitor until settling down in Utah, told me that he almost never used jacketed bullets, with the exception of product tests, because he couldn’t make them shoot as well as the cast bullet loads he used to collect hundreds of championship medals from all over the world that filled glass display cases in his trophy room. John also used cast bullets exclusively when hunting feral hogs along the Virgin River in northwest Arizona and big game in Utah and Texas.

We could also get to more recent writers, but the point is clear, nearly all of the name writers of the 1930s, 40s, 50s, 60s and 70s, several of whom graced the pages of the American Rifleman’s “Dope Bag,” earned their bonafides with cast bullets in rifles and handguns prior to gaining respect among regular folks in the shooting and hunting world. Many of them also used their cast bullet experience to develop the idea of swaging jackets on cast bullets or cores to permit higher velocities and, to some degree, improve accuracy potential. Dave Corbin of Corbin Swaging (corbins.com) in White City, Oregon, helped to create a minor industry by developing and manufacturing custom swaging dies for use with cast cores or lead wire and still does for experimentally minded handloaders.

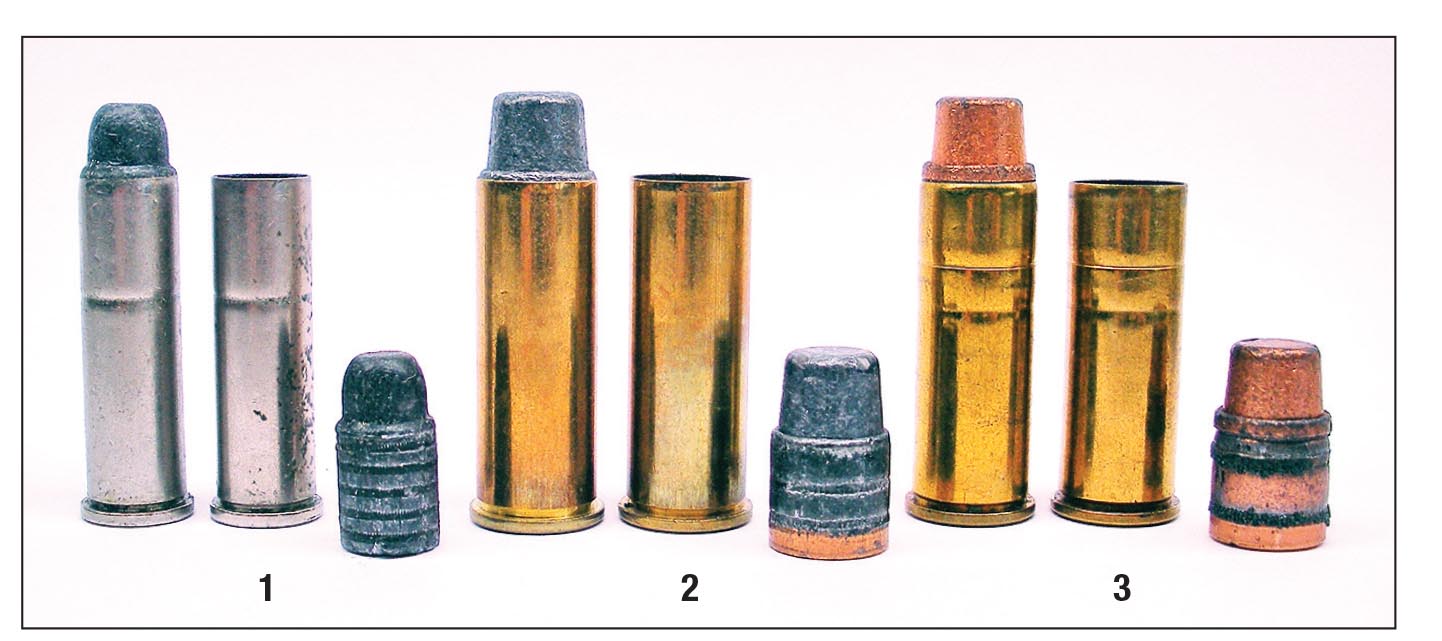

If the idea of swaging jacketed handgun or rifle bullets appears burdensome and time consuming, bear in mind the original .357 Magnum factory loads were topped off with swaged lead bullets, no jacket and no gas check. It took people like Dave Corbin to make it possible to shoot more than 10 rounds of those .357 Magnum loads without lead plating the barrel from one end to the other. The first .44 Magnum factory loads were improved a bit by adding a gas check, and the Winchester load had a Lubaloy (plated) bullet. From that it should be obvious that Remington and Winchester had little to do with the development of jacketed handgun bullets until they purloined (stole) the idea from folks who were willing to do the grunt work.

During the years that I manned the “About Cast Bullets” column, there were always questions asking about the best alloy and/or bullet lubrication for whatever cartridge. Folks were obviously interested in obtaining good accuracy, but no one wanted to spend time scrubbing lead alloy out of chamber throats and revolver barrels. Almost universally, they were under the impression that barrel leading is worse than copper fouling from jacketed bullets. My standard response, drawing from years of experience with cast bullets, was that scrubbing lead fouling out of a handgun or rifle barrel was often a lot less troublesome than removing copper fouling. That is, assuming the bullet alloy is appropriate for the velocity and pressure developed by the loads, what leading that might occur was not enough to seriously affect accuracy.

More often than not, I included a note to mention Elmer Keith’s favorite cast bullet alloy was one part tin to 16 parts lead, the same composition as the lead alloy used in government .45-70 bullets. In specific terms, that is a bit softer (Brinell hardness number [BHN] 11) than Lyman No. 2 alloy (90/5/5, lead/tin/antimony – BHN 15) and harder than typical black-powder (1:40, tin-to-lead) alloys for the .45 Colt (BHN 8.5), for example. You can read Elmer Keith’s SIXGUNS by Keith cover to cover, and he never varies from his 429421 Lyman/Keith bullet design sized to not over .430 inch over 17.5 grains of 2400. He used the same alloy for those bullets in the .44 Magnum.

(Come to think of it, there are only two hunters/shooters/writers in recent history that most hunters and outdoorsmen can quote their loads – Keith and that other fellow from Idaho . . . err, uh . . . O’Connor.)

Where pressure and velocity are over 20,000 psi and upward of 1,300 fps, for example in a .44 Magnum with Keith’s bullet, you can upgrade the alloy to 92/6/2 (lead/antimony/tin) often referred to as Taracorp Magnum bullet alloy that was developed by Paul Moore several years ago for commercial cast bullet outfits. Paul told me years ago that anything over two percent tin is not only a waste of money, but also unnecessary. Either way, his alloy works fine for hot-rod loads but is a bit too hard for traditional target velocities and pressures. This can result in gas cutting on the rear band and heel of a too hard bullet that leaves streaks of alloy from the forcing cone. Without an occasional light barrel scrubbing, leading will eventually reach the muzzle.

Twenty years ago there were a number of bullet lubricants that were quite firm, intended for harder alloys used at high velocities and pressures. I have not found them necessary, and in some situations almost useless in terms of preventing leading if the bullet does not form a proper gas seal in the chamber before it enters the barrel.

For the most part LBT Blue, RCBS Green and SPG should help eliminate or minimize barrel leading at normal handgun and rifle velocities associated with cast bullets. More recently Lyman Super Moly has also proven to be quite useful in my sixgun loads that rarely exceed 1,000 fps at 20,000 psi in .44 Special, .45 Colt and .38-44 using standard 1:16 Keith alloy. Under normal use – up to 50 rounds during a day of hunting varmints, rabbits or prairie dogs – leading is not a problem.

While a number of people have expressed reservation about bullet casting, and local or state laws that discouraged and/or made the use of cast or lead bullets indoors unlawful, it is still a valid option for target practice outdoors. I’ve been casting and shooting cast bullets for roughly 45 years, and regular blood tests have failed to show lead traces – mostly because I use a fan to blow fumes away while casting and shoot outdoors. It is also important to avoid putting your fingers or hands anywhere near your mouth while casting or shooting. Lead naturally occurs in nature and is a by-product of mining for copper, silver, gold and zinc. That means stay away from old mining shafts or tailings; you never know what dangers lurk. Out West that includes the obvious danger to your health: snakes, lizards and/or other critters that bite or sting.

The most obvious and best option to casting your bullets is to order a supply from any of the commercial outfits that advertise in this magazine. Plated bullets are also a good option. A blatant sales pitch no doubt, but common sense, like it is to wear mechanic gloves while handling cast bullets.

While an old dude who lives in the high and dry mountains of Arizona or those renegades – Haviland, Barsness and Venturino up in Montana and that cowboy Pearce in Idaho – who cast bullets regularly, it is one of those great ironies that many folks who are reading this are sucking in all kinds of urban pollution yet often appear to be overly focused on lead, which for the most part is avoidable. Looking back over the last 45 years, I probably faced more potential lead exposure while helping my parents paint our home, and the dreaded picket fence thereafter, than casting bullets out in the garage with a big fan blowing fumes out the door.