To Die For

Sizing Up Reloading Dies

feature By: Jason Stanley | August, 23

Many reloaders take the resizing die for granted. A common misconception is that the case is being resized correctly if the die is labeled the same as the cartridge. Well, maybe, but that depends on which rung of the precision ladder the rifle is on. For a particular rifle, comparing required precision to the rungs of a ladder is a useful metaphor. This correlation will help determine which resizing die will work best for the rifle.

Precision Ladder

Moving up the precision ladder are the rifles in which the shooter handloads the ammunition. These rifles are essentially the same as rifles on the first rung. The difference is the ability to tune using handloads, thus gaining precision.

The resizing die, used for these rifles, has three main uses. First, to push (bump) the shoulder back. Frequently, this job of the resizing die has more to do with how the user sets up the die in the press than the die itself. Second, resize the neck. Again, this has more to do with the expander button or bushing size than the die. Third: allow the brass to be safely chambered. This amount of “squeezing” will be dictated by the internal dimensions of the die relative to the chamber.

Take another step up the analogy ladder and we run into the precision rifles. Rifles on this rung are partially or fully custom and are tuned using handloads. This smaller group of handloaders understands there is more to the resizing die than just allowing the brass to be safely chambered. These experts comprehend the balancing act between too much and not enough resizing.

At the top of the precision ladder is the tiny group of rifles whose shooting demands the highest degree of precision and accuracy. These are the target and competition rifles. Largely custom and meticulously tuned to shoot the smallest groups in the world.

Reloading for a competition rifle has crossed the line from luxury to necessity. For these competitors, everything that affects the bullet’s path, either directly or indirectly, needs to be accounted for. This includes the extent and location the resizing of the case takes place.

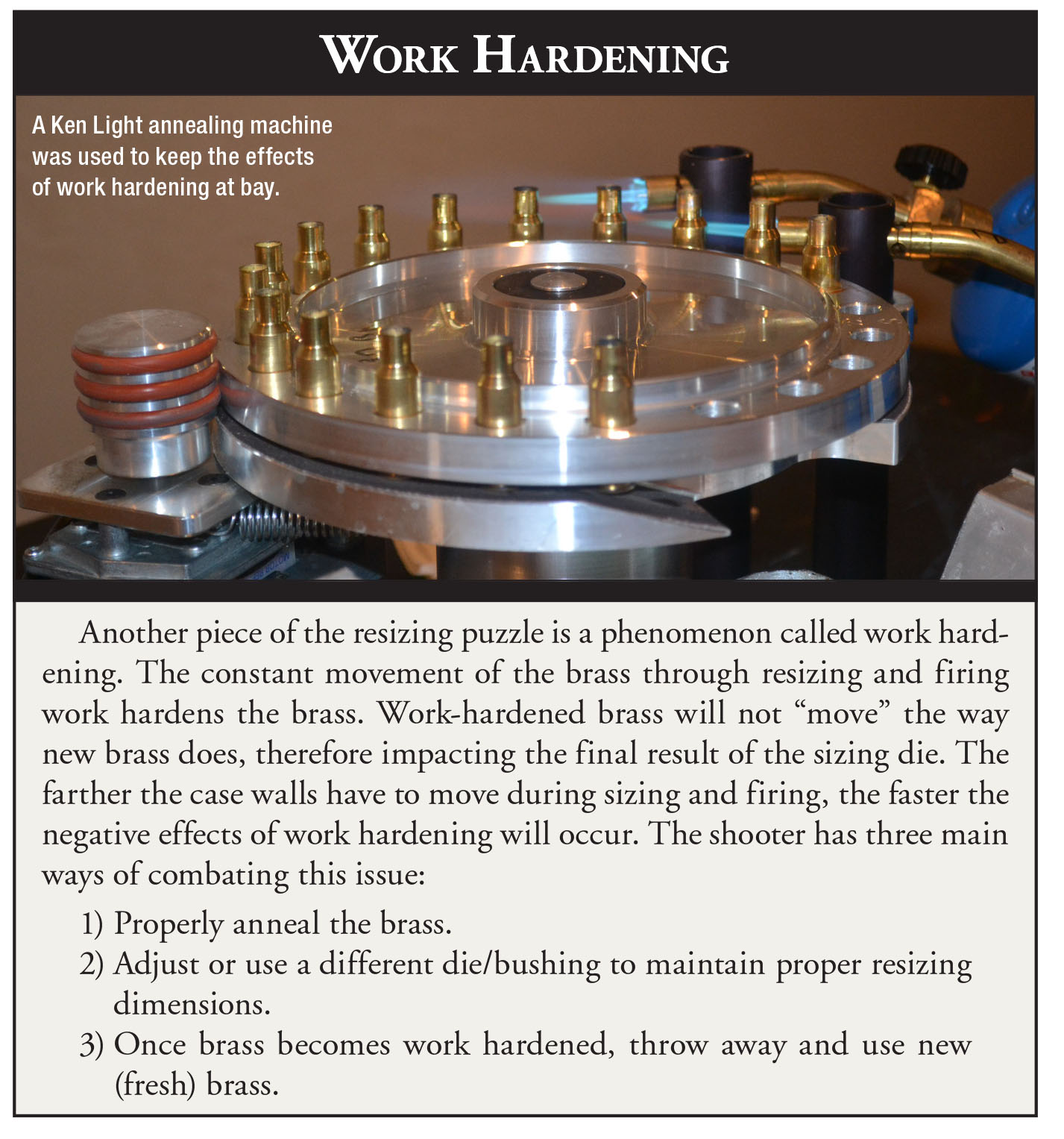

No More - No Less

Signs of inadequate resizing (tight headspace) in relation to a particular chamber are: “hard” closings, clicks when uncocking the bolt, and in extreme situations, high-chamber pressures. On the opposite end of the resizing teeter-totter is when the brass is resized too much. When a case is fired that has excessive headspace, it can lead to case growth, case work hardening and decreased case life. Bulged cases and even case failure can happen in extreme cases.

The closer the resizing die correctly aligns to the chamber, the less these negative effects will be noticed. For rifles on the bottom couple of rungs of the precision ladder, slightly varying dimensions are a nonissue. There are much larger pieces to the precision puzzle than the negative effects caused by minimal differences in chamber reamers/die dimensions. Many of the mass-produced resizing dies will work fine for these rifles.

However, for top-of-the-ladder rifles, these adverse consequences need to be avoided.

For competition/target shooters, one major drawback of insufficient resizing is the round “chambers hard.” The extra force needed to close the bolt can upset the rifle in bags, throwing the next shot off the mark. Inadequate resizing can also lead to the dreaded “click.” This condition is caused when the base of the case is incompletely resized and causes the brass to get “stuck” upon extraction. The result is a harder bolt lift with a tactile and audible “click” at the top. To a competitor, the “click” upsets the rifle in the bags, takes focus away from the wind indicators, and uses up precious seconds while the chosen condition is holding.

Custom Diemakers

Once a rifle reaches the third and fourth rung of the ladder, the key to resizing is correctly aligning the chamber and die dimensions. This means proper shoulder and base resizing. To find this “perfect” die, the reloader might get lucky and find a mass-produced die that fits the requirements, or one must open a new door to precision reloading. Behind that door are custom diemakers.

One of those diemakers is Chris Westmoreland at Harrell’s Precision in Salem, Virginia. Harrell’s Precision is a family-run business started by Lynwood and Walter Harrell. Chris married into the family 35 years ago and is their main CNC operator.

Westmoreland programs the CNC machine to make eight different sized dies for each popular target caliber. These dies increase the resizing by .0005 inch for each step up on its numbering scale. For example, a 2.5 would size .0005 inch more than a 2.

Once machined, the internal dimensions of each die are measured and recorded. The dies are then sent off for heat and cryo treatment. When the dies are returned, they are remeasured to ensure the internal dimensions did not change during the hardening process.

Harrell’s asks the customer to send in three cases that have been fired three times from a particular chamber. Chris then matches up the die that will work best for those case dimensions. When needed, they will hand-polish the die to meet the desired resizing amounts.

Another custom diemaker is Jim Carstensen, who is the founder of JLC Precision in Bellevue, Iowa. Among other things, Jim specializes in custom dies and die conversions.

Jim likes his die to resize .0005 inch just below the shoulder. At a point .200 inch above the base of the case, the minimum amount of resizing is .0015 inch and .002 inch is considered “safe.”

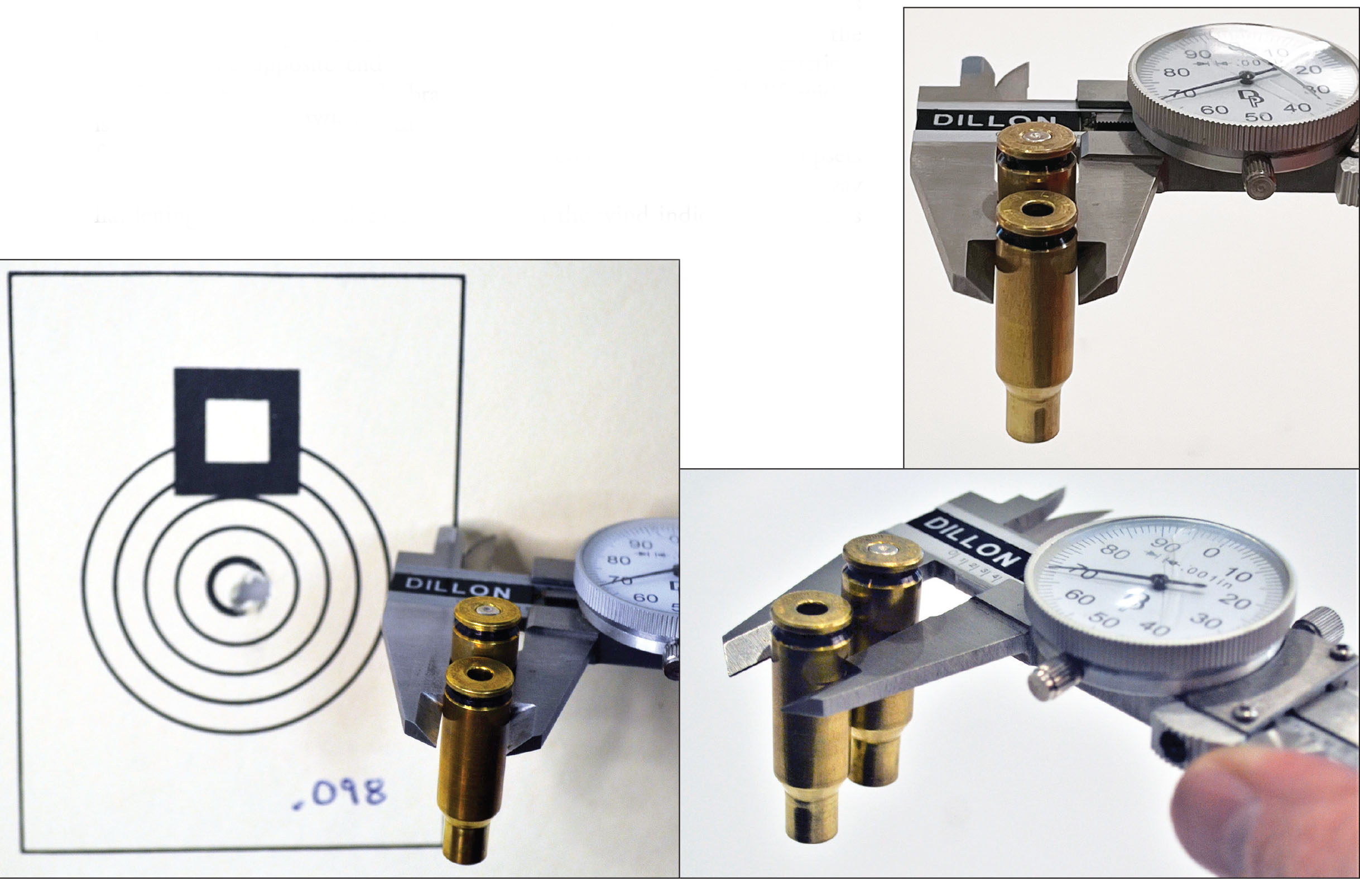

A micrometer is the tool of choice to measure these dimensions. However, there is a “quick check” method that Jim likes to use for the all-important base. Hold a fired case and a resized case side-by-side with the primer pockets facing up. Gently close the jaws of a caliper at the .200-inch mark. The jaws will shut on the fired case, but a properly resized case should slide down just above the base before it stops.

Although done differently, the result of both dies is fundamentally the same. A resizing die correctly fitted to a particular chamber. These dies will resize the case just enough to be safely and easily chambered without the dreaded “click” upon extraction, yet not so much to induce case excessive headspace, case growth and work hardening. All of which are vitally important to the rifles on the upper rungs of the precision ladder.

Having the correct resizing die will help shooters squeeze the utmost precision and accuracy out of their rifle. Knowing what “correct” means depends on which rung of the precision ladder the rifle is on.