7mm Remington Magnum

Loads for New IMR and Reloader Powders

feature By: John Haviland | June, 17

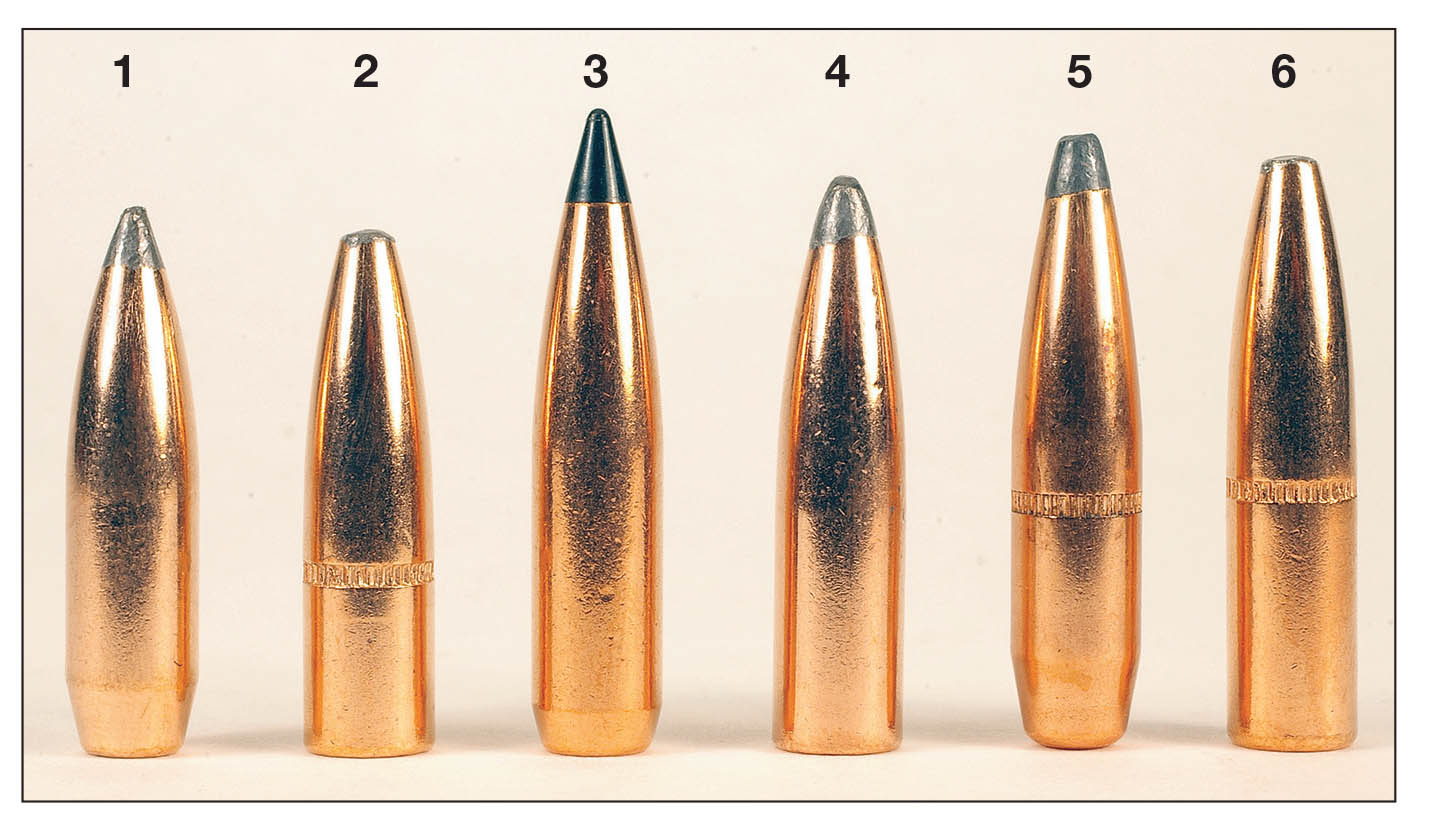

Handloaders always welcome new powders in their endless effort to improve the velocity and accuracy of their loads. So in anticipation of stepping up the performance of my 7mm Remington Magnum, new powders have been tested, including Alliant Reloder 17, 23 and 33; and IMR-4451, -4955 and -7977. Most of these powders worked well with a range of 7mm bullet weights, while one was limited to a single weight bullet.

Several of the powders contain features such as the ability to maintain consistent velocities over a wide variation in temperatures, an additive that reduces buildup of copper fouling in the bore and the elimination of dinitrotoluene as a deterrent coating and dibutyl phthalate as a stabilizer. Alliant calls this chemical technology EI technology, and IMR calls it Enduron Technology.

IMR Powders

The addition of nitroglycerine makes the Enduron powders IMR’s first double-based rifle powders. IMR-4451 has a relative burn rate right next to IMR-4350 and Hodgdon H-4350. IMR states the powder provides top performance in cartridges that include the .30-06 and .300 Winchester Short Magnum and is ideally suited for cartridges that thrive on powders in the midrate burn range. IMR-4451’s burn rate is fairly fast for the 7mm Magnum but is an adequate choice paired with lighter bullets in the cartridge.

With a seated bullet, IMR-4451 does not completely fill a 7mm Magnum case. That resulted in some rather high extreme velocity spreads. The lowest extreme spread was 46 fps with Speer 145-grain boat-tail softpoint (BTSP) bullets. The highest spread was 113 fps with Speer 145-grain Grand Slams followed by 111 fps with Hornady 162-grain BTSPs. However, group sizes were not all that much different than other powders shot in a Browning X-Bolt Speed rifle, which was used to shoot all the loads listed in the accompanying table.

IMR-4955’s relative burn rate falls between H-4831 on the fast side and Reloder 22 on the slow end. That puts 4955 solidly in the traditional range of the most useful powders for the 7mm Remington Magnum. The powder produced extreme velocity spreads of 48 fps with Speer’s 145-grain Grand Slam, 35 fps with the Swift 150-grain Scirocco II, 38 fps with the Speer 160-grain Hot-Cor spitzer and 33 fps with the Speer 175-grain Grand Slam. It is not unusual for velocity spreads to narrow as bullet weight increases. Except for a couple of instances, 4955 produced the best groups from the Browning rifle. If accuracy and velocity of all the bullets tested are added together, IMR-4955 was the across-the-board winner for the test rifle.

To see how well the Enduron Technology reduced buildup of copper fouling in the bore, I looked in the bore before and after shooting IMR-4955. The barrel was thoroughly soaked and cleaned with Gunslick’s Foaming Bore Cleaner until a Lyman Borecam Digital Borescope showed it was completely free of copper fouling. Images of the clean bore were taken at 8, 13 and 19 inches in from the muzzle. After firing 25 cartridges loaded with IMR-4955, I mopped out the bore with citrus cleaner to remove powder fouling and again took images at the same three intervals. At the spot closest to the muzzle, there was some copper fouling on the sides and tops of the lands. At the second place in, there was a slight wash of copper on the tops of the lands. At the deepest location in the bore, the tops of the lands were covered with a smear of bright copper. The bore was clean again after an hour’s soak with foaming bore cleaner, followed by a couple of patches to push out the gunk. The powder reduced, but did not eliminate, copper fouling, but it appears that it did make it easy to remove.

IMR-7977’s relative burn rate sits between Reloder 25 on the fast side and H-1000 on the slow end. A maximum amount of 7977 with 150-grain and heavier bullets fairly well filled a 7mm Remington Magnum case. The powder packed into place produced fairly low velocity spreads. For example, Swift 150-grain Scirocco II bullets varied 84 fps; Speer 160-grain spitzer bullets varied

31 fps; and Speer 175-grain Grand Slams varied 40 fps. Velocities produced by 7977 were about 100 fps slower across the board than those stated by Hodgdon, i.e., 2,955 fps for the Hornady 162-grain BTSP with 69.5 grains of 7977 from a 24-inch barrel. Sixty-nine grains of the powder with the Hornady bullet reached 2,866 fps from the Browning’s 26-inch barrel.

Alliant Reloder Powders

Reloder 17, 23 and 33 are extruded powders and, according to Alliant, provide consistent velocities across temperature and humidity extremes. Reloder 23 also contains a decoppering additive. In fact, Alliant has been using an additive that prevents a buildup of copper fouling since 2002 in all its Reloder powders, except Reloder 17. (As an aside, I looked high and low but could not find the new Reloder 26 powder to include.)

Alliant powder charges used here are from the Reloading + Reloading Accessories 2016 catalog published by RCBS, Alliant,

Speer Bullets, Federal Premium and CCI. The catalog states: “The powder charge weights listed in our data tables are maximum. For rifle and pistol loads, the maximum powder charges should be reduced by 10 percent to establish a minimum or starting powder charge.”

Reloder 17 (RL-17) is not a new powder. I included it because on the Internet a fellow posted fantastic speeds he received with the powder and 140-grain bullets from his 7mm Remington Magnum. He used a stout charge of RL-17 with Barnes 140-grain Tipped Triple-Shocks, Nosler AccuBonds and Hornady 139-grain InterLock bullets, with velocities up to 3,376 fps. A glance in a reloading manual, though, showed his powder charge was at least 5.0 grains over maximum. I loaded 61.0 grains with Speer 145-grain BTSPs for a velocity of 3,044 fps. Sooner or later the fellow will destroy his rifle, and maybe his face. In my tests, velocity spreads were rather high. Speer 145-grain BTSP bullets varied 141 fps, and Speer 160-grain bullets spread 111 fps.

Reloder 23 generated velocities with 145- to 175-grain bullets about as fast as any of the powders tested. Velocity spreads were also low: 53 fps with Swift 150-grain bullets to 25 fps with Speer 175-grain Grand Slams. Low extreme velocity spreads are just as important as a powder’s capability to produce even velocity over a wide range of temperatures.

Reloder 33’s burn rate is a bit too slow for general use in the 7mm Remington Magnum, but it fired Speer 175-grain Grand Slam bullets faster than other powders and gave the smallest group. Ten more grains of RL-33 were required to gain 4 fps of velocity over RL-23, and 6.5 more grains than IMR-7977 to gain 75 extra fps.

All the powders listed here are extruded. These “stick” powders do not dispense from a powder measure quite as precisely as spherical powders. I dropped 10 charges of each powder from a measure and weighed them to see how much weights varied. The results follow:

IMR-4955 varied 0.7 grain; six charges were within 0.2 grain. IMR-7977 varied 0.7 grain; four were within 0.2 grain. IMR-4451 varied 0.6 grain; six were within 0.2 grain. RL-17 varied 0.4 grain; eight were within 0.2 grain. RL-23 varied 0.5 grain; six were within 0.2 grain. RL-33 varied 1.0 grain; four were within 0.2 grain.

The spreads in charge weight are fairly close. If loading a minimum amount of these powders to assemble practice loads, I would dump the powder right into cases. Though with powder charges close to maximum, I set my measure a couple of grains light of the intended weight, drop the powder onto a scale and dribble in the last bit to bring it up to the correct weight. An electronic powder dispenser would also work, if you want to stare at the wall while it takes forever to dribble out the powder.

Case Sizing and Case Life

As with several other cartridges that utilize a belt to set headspace, new 7mm Remington Magnum cases and loaded cartridges are often short at the shoulder. The position of the belt does keep the case head in tight contact with the bolt face, but if a case is short on the shoulder, a belt does not prevent it from stretching at the web as a cartridge fires and expands to fill the chamber.

For example, new Remington cases measured .018 inch short from the case head face to the datum line on the shoulder compared to a case fired in the Browning X-Bolt rifle. Federal Premium Vital-Shok and Hornady Precision Hunter cartridges measured .016 inch short at the shoulder compared to those brands of cases fired in the X-Bolt.

In contrast, cases that do not have a belt headspace on the shoulder and have a much tighter fit in a chamber. Winchester Supreme .270 Winchester cartridges measured only .003 inch shorter from the case head face to the datum line on the shoulder compared to fired Winchester cartridges.

That big of a stretch of 7mm Remington Magnum cases on the first firing has most likely excessively stretched the cases at the web and ruined them. It will not matter if the belt is ignored and headspace is set on the case shoulder when sizing the cases, because the damage has been done and cases have at least had their life significantly reduced.

To fix the problem with new brass, expand the necks by running them over a larger expander ball, like a .30 caliber. A bit at a time, size the necks back down so the cases just fit in a chamber. Load the cases with a minimum amount of powder listed in a handloading manual, add a bullet and fire them. The remaining portion of the expanded neck keeps the case tightly in the chamber at the shoulder and against the bolt face, and shooting them fireforms the brass to match the chamber with no stretching at the web.