Wildcat Cartridges

.255 Banshee

column By: Richard Mann | June, 17

Several years back, a couple of Reeder’s handguns were sent to me for review. One of those was a revolver chambered for the .255 Banshee; the other was a big-bore .50 GNR. I’ve been a fan of Gary’s work ever since.

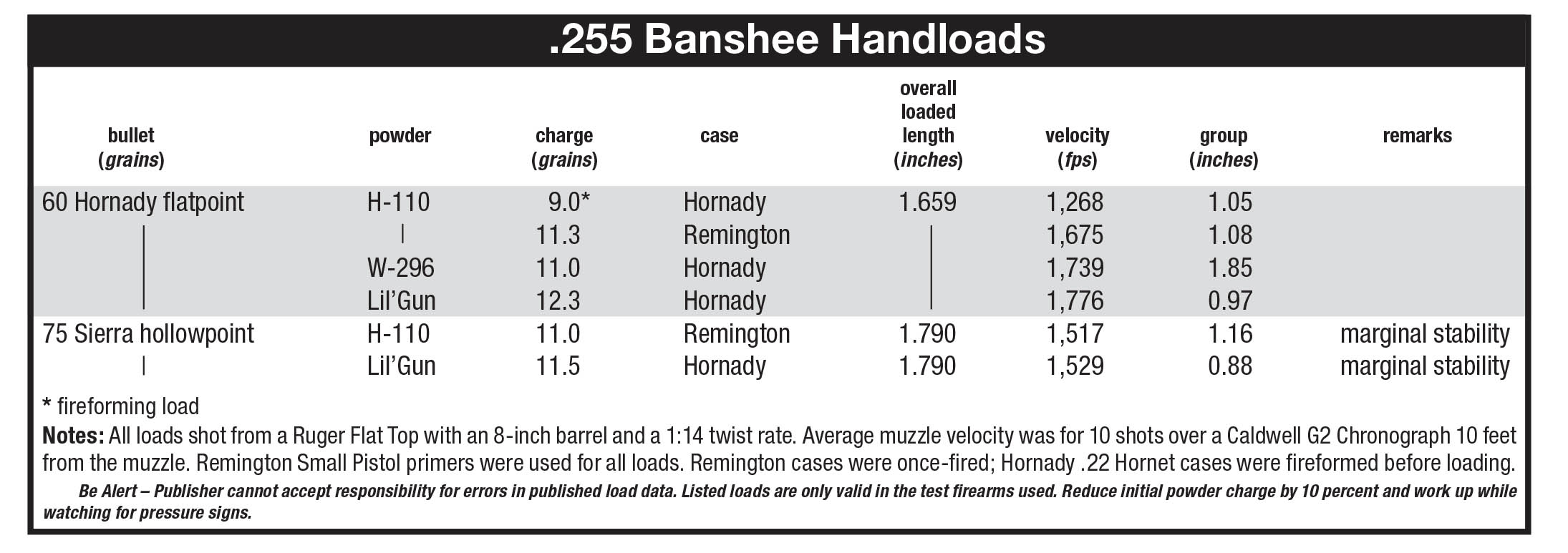

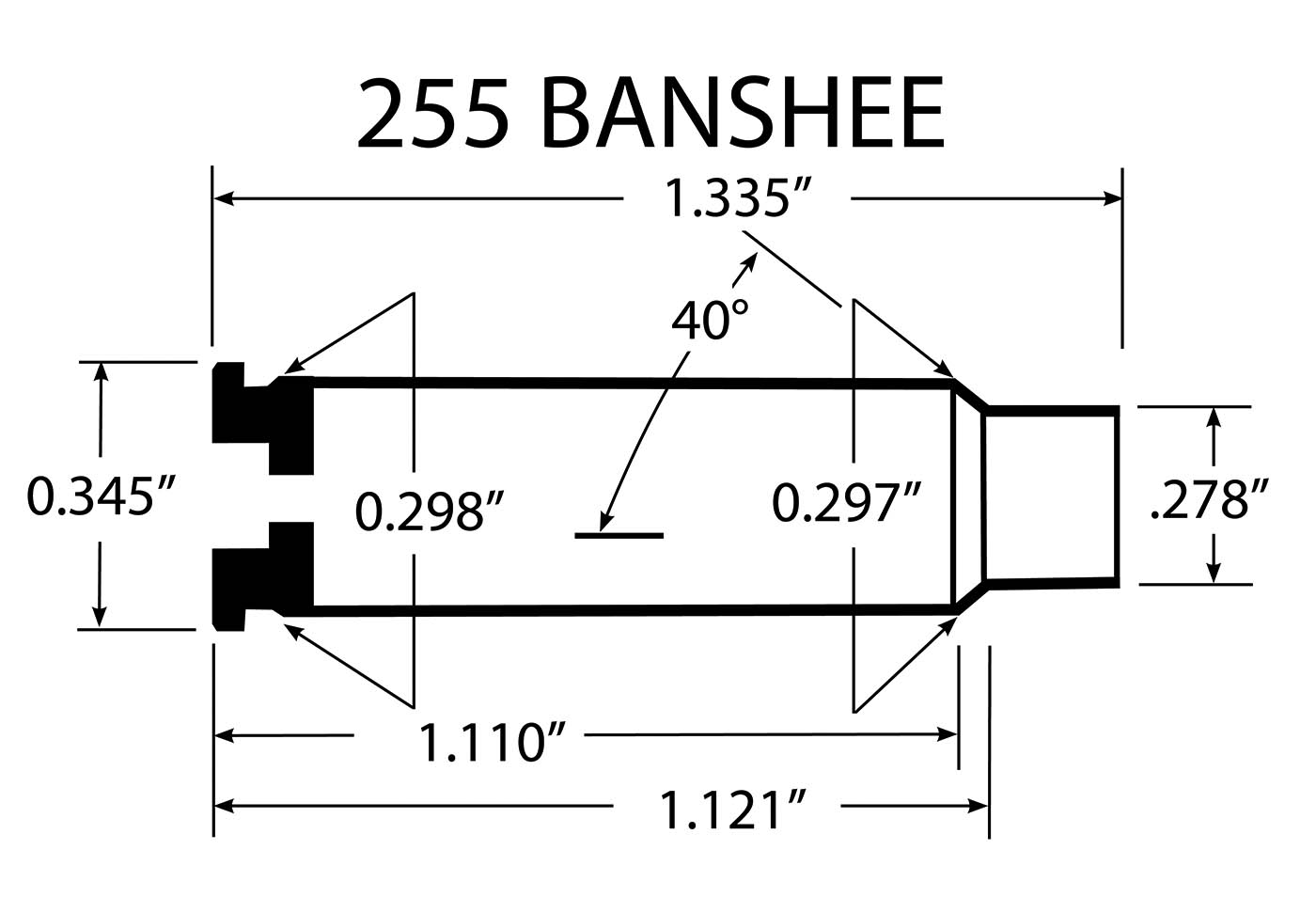

With the .255 Banshee case, the taper in the .22 Hornet case is removed, and a sharp shoulder is set at 40 degrees behind a case neck that is 0.214 inch long. To achieve this case shape, fireforming is required. Reeder suggests reducing maximum loads by 10 percent for fireforming. He supplied some already-formed Remington cases, but I needed more, so 50 .22 Hornet cases were sized and fireformed. A load of 9.0 grains of Hodgdon H-110 was used behind a Hornady 60-grain flatpoint bullet. Surprisingly, these loads shot pretty darn well, averaging just a shade larger than an inch for five, five-shot groups at 25 yards from a sandbag rest. These fireforming loads had an average muzzle velocity of 1,268 fps. This was about 28 percent slower than the fastest load tested with this bullet.

Before getting too far along, it is interesting to note why the cartridge was created. Reeder wanted a cartridge that would push a 65- to 75-grain bullet out of a 12-inch pistol barrel at close to 2,000 fps. In his reloading manual – yes, he has his own – Reeder says, “The cartridge will do very well with bullets in the 60- to 85-grain weight which surprised me a bit. . . . The .255 Banshee does very well on smaller bodied deer and other game smaller in size.”

The test gun supplied was a highly customized three-screw Ruger Flat Top with an 8-inch barrel with a one-in-14-inch twist. In his loading manual, the Hornady 60-grain flatpoint bullet is listed as producing in excess of 2,100 fps from a 12-inch Contender barrel. My highest-velocity, 60-grain loads came in 400 fps slower, which would suggest a loss of about 100 fps per inch of barrel.

If you want maximum performance with the .255 Banshee in a revolver, there are two issues. The first is that overall cartridge length is limited by cylinder length. The revolver provided had a cylinder that measured 1.755 inches long. This limited overall cartridge length to a maximum of 1.810 inches, because the overall case length includes the case rim outside the cylinder. Cartridges loaded too long will not permit the revolver cylinder to rotate. With a single-shot pistol like the Contender, this would not be a problem, and bullets could be seated farther out.

The other issue with a revolver chambered for the .255 Banshee is barrel length. A Contender with a 12-inch barrel is not much longer than a revolver with an 8-inch barrel. If 2,000+ fps velocities are desired, a single-shot pistol with a 12-inch barrel makes sense.

All that said, there is nothing wrong with an 8-inch .255 Banshee revolver. It pushed the Hornady 60-grain flatpoint bullet 1,776 fps, and 25-yard groups averaged less than an inch. At the muzzle, this load produces 420 foot-pounds of energy. That’s 25 percent more energy than from a .22 Winchester Magnum rifle. It’s also about the same level of energy that can be expected from a .327 Federal Magnum revolver, and I’ve taken several deer using that cartridge.

This velocity issue with the shorter 8-inch revolver barrel created the only problem I had with any of the loads assembled. Due to their length, the 87- and 90-grain loads just would not stabilize at the velocities the revolver was capable of generating. Ideally, they would have needed a twist rate of 1:8 to keep from tumbling when shot from the test revolver’s 8-inch barrel. From a 12-inch barrel, these loads theoretically should produce enough velocity to stabilize in a 1:10 or 1:11 twist, but that still puts them on the borderline of working with the standard 1:14 twist rate Reeder uses for the .255 Banshee. This is no knock on the cartridge; a faster twist rate and/or a longer barrel would sort out most of this.

Regardless, bullets ranging in weight from 60 to 75 grains seem about right for the cartridge. Even 87- and 90-grain bullets pushed about 1,700 fps are not likely to expand very much – or at all – when impacting critters at any distance, because they are engineered to work at higher-impact velocities. The 70-grain V-MAX, on the other hand, requires a 1:10 twist rate for the 1,450 fps velocities it was being pushed to. It should expand – maybe out as far as 100 yards. Out of a 12-inch barrel at roughly 2,000 fps, a 1:12 or 1:14 twist should be suitable.

Though the .255 Banshee is indeed a niche cartridge, it is fun to shoot and easy to load. For smallish game like coyotes, foxes, bobcat and javelina, it should be ideal, and the Hornady 60-grain flatpoint or the Sierra 75-grain hollowpoint should work just fine. At modest handgun ranges, I’d not hesitate to shoot a common-sized whitetail with either load.

Something that has not been mentioned is recoil. In hand the revolver bucked something like a .38 Special with maybe a little more snap, but it was comfortable to shoot. Muzzle blast, on the other hand, was noticeable, especially when using Hodgdon Lil’Gun powder. I would not say it was objectionable, but there was a noticeable fireball.

Many handloaders understandably will shy away from a cartridge that necessitates fireforming cases. The fireforming process with the .255 Banshee was headache-free. More important, the fireformed loads were accurate, easy to extract and would suffice for small-game hunting. Fifty rounds of new .22 Hornet brass can be processed in about 30 minutes.

Gary Reeder likes to create cartridges that are more on the specialty as opposed to the general-purpose side of the fence, and the .255 Banshee is indeed a special purpose cartridge.