Bullets & Brass

Shooting Special Cartridges in Magnum Chambers / I Need a 44-40 Load to Shoot Point of Aim / Bore vs. Groove Diameters

column By: Brian Pearce | July, 25

Shooting Special Cartridges in Magnum Chambers

Q: My question has to do with shooting 38 Special cartridges in 357 Magnum revolvers, 44 Specials in 44 Magnums and 45 Colts in 454 Casull revolvers. I have used them without any real problems; however, as you have previously said in these pages, the crud buildup in front of the shorter cases must be removed prior to firing the magnum cartridges.

Besides the house cleaning issue, how does the accuracy compare? And are there any other issues that I am overlooking? Lastly, should I use special or magnum cases for light target handloads?

Benson, via Facebook

A: This has been a controversial subject for a long time. Here goes my two cents’ worth. Most manufacturers recommend using specials and magnum cartridges in their guns, but not all. For instance, Freedom Arms does not recommend using the shorter cases due to erosion of their mirror shiny chambers, which can ultimately lead to sticky extraction with full-power high-pressure loads such as the 454 Casull. Not everyone is faithful about cleaning chambers prior to firing magnum rounds, which makes it very difficult to remove. In extreme instances, has been known to cause some damage to the chambers.

As to accuracy, I have read many test reports on this subject for more than 50 years. They do not always agree on the results. However, most of the testing has been at 50 feet to 25 yards, which is not conclusive. As Elmer Keith always stated, “Long-range shooting is the real test of any revolver or pistol. True, some loads were never intended for any but short ranges, but in the main, long-range shooting will prove both gun and load.”

Based on my natural curiosity and extensive testing in a huge number of sixguns, various cartridges and loads that have included both jacketed and cast bullets, accuracy is almost always better when loads are fired from magnum cases. This may not be particularly apparent when fired at shorter distances, such as the previously mentioned 50 feet or 25 yards, but extend the distance out to 200 to 500 yards, and the difference becomes quickly apparent. My testing has included using the same bullet in special and magnum cases, with the same powder, but the charge adjusted so that bullets exit the muzzle at more or less the same velocity.

Space will not allow a great amount of detail, but in essence, the bullet jump from the case to the rifling is increased when fired from special cases, which has proven many times to decrease accuracy. An even greater problem is that the bullet is poorly aligned with the throat and axis of the bore. This often results in the bullet tilting, which can cause some degree of bullet deformation prior to it entering the barrel. When bullets exit the barrel, there will almost always be some degree of yaw, but if damaged, they will have a difficult time fully stabilizing.

Magnum cases on the other hand, reduce bullet jump and most bullets are positioned to rest in the throats, giving better alignment with the axis of the bore. This results in reduced deformation and better overall accuracy.

With so many excellent modern powders that are not position sensitive, using light loads in magnum cases can yield very low extreme spreads and excellent accuracy.

If it is of any interest, rifles chambered for magnum revolver cartridges likewise give their best accuracy with loads assembled in magnum cases.

Despite the above thoughts, I know that sometimes a given load assembled in special cases and fired in magnum chambers can shoot very well. However, generally speaking, the magnum case will give better accuracy.

I Need a 44-40 Load to Shoot Point of Aim

Q: I have a Colt Single Action Army 44-40 third-generation gun that shoots very well using a 225-grain cast bullet from MP moulds using either 8.0 grains of Alliant Unique or 35.0 grains of black powder. The problem is that the point of impact is about 6 inches high at 25 yards. Do you have any suggestions on how to get my gun to shoot to the point of aim? I greatly appreciate your articles on handloading, as you provide data and information not available anywhere else.

George, via Facebook

A: One of the drawbacks with fixed sights is the very problem you are experiencing. The most practical fix is to change to a 200-grain cast bullet that should bring your point of impact down and close to the point of aim.

Other options will require sight alterations, such as having the front sight welded with a higher profile, which will cause discoloration, and you will probably need to re-blue the barrel. Many old timers would deepen the rear sight notch of their SAAs so that they could place just the tip of the front sight in the bottom of the rear sight notch to allow bullets to hit at the point of aim. However, you may not want to choose an option that will decrease the value of your relatively new sixgun! Other options are even more entailed and would include installing an adjustable rear sight or a dovetailed front sight.

But again, choosing a lighter bullet, such as the RCBS mould 44-200-FN, is the most practical choice.

Bore vs. Groove Diameters

Q: I am relatively new to Handloader magazine. I have learned much from reading each issue. I am currently handloading for eight different cartridges and am enjoying my new hobby. Through this journey, I have learned a great deal more about my guns.

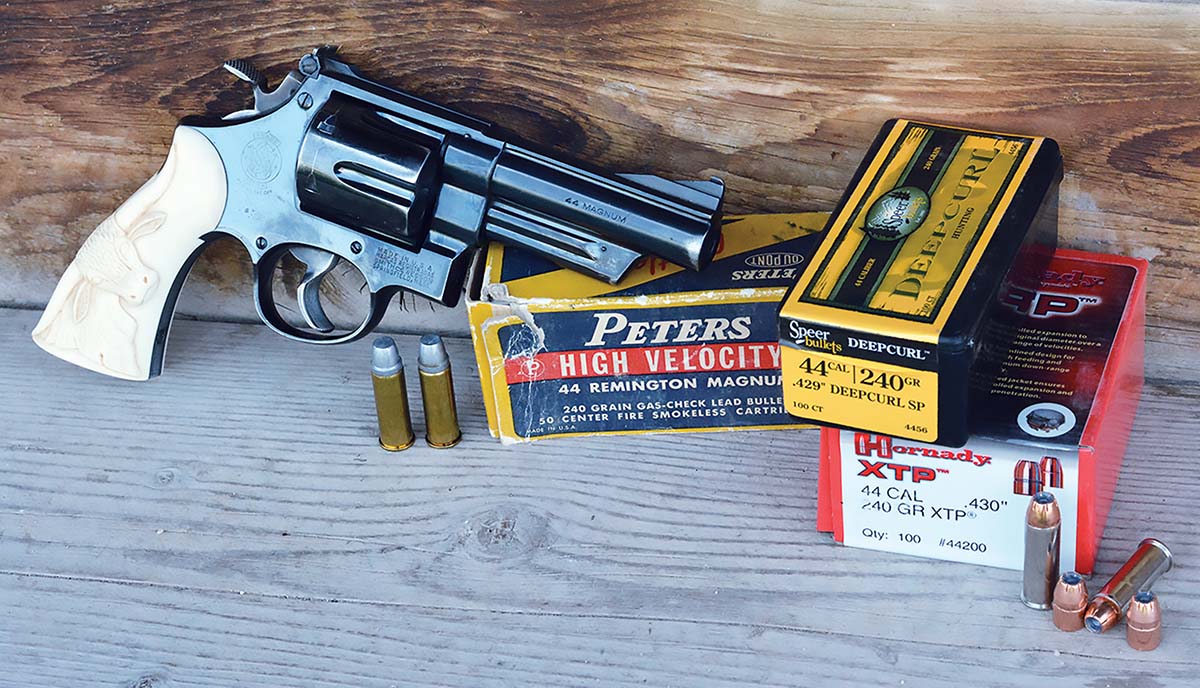

My question today has to do with bore versus groove diameter. In reading articles and books, I often hear both used nearly interchangeably. One of the guns I handload includes a Smith & Wesson Model 29 in 44 Magnum. Some period literature that came with it indicated that Smith & Wesson listed the bore diameter at .430 inch. This really confused me, as I thought that would be the groove diameter and would explain why I use .430-inch bullets for handloading. Can you clarify why some refer to bore and groove diameters interchangeably?

Leo A., Bend OR

A: You are not confused; rather, the two terms have caused confusion for generations and are often incorrectly used! I have seen incorrect references dating back more than 150 years and even including military brass. The bore refers to the lands and not the groove diameter. In fact, bore indicates the “boring” diameter, or “gun drilling,” of the barrel prior to the rifling being cut to create the grooves.

I am not sure what literature you are referring to from Smith & Wesson, but the factory identified the pre-Model 29 44 Magnum as “NT430,” which indicated an N-frame, target revolver with a .430-inch groove diameter instead of a bore diameter. So, whoever wrote the literature was clearly confused!

Thank you for taking the time to read Handloader magazine.