Propellant Profiles

Evolution of Propellants and Internal Ballistics (Part One: Black Powder)

column By: Rob Behr | July, 25

With the first of the three ingredients required for black powder firmly in hand, Chinese alchemists only needed to combine two naturally occurring chemicals to the mix. Sulfur is the fifth most common element on Earth by weight and was well known to Chinese alchemists. The final ingredient, some form of carbon, is readily found as a result of wood combustion and has been observed since the earliest days of human history. When black powder was first created is lost to antiquity, but by 808 A.D., a Taoist monk named Qing Xuzi in his work the Taishang Shengzu Jindan Mijue, provided a formula for gunpowder calling for six parts sulfur, six parts saltpeter and one part birthwort herb. Less than a century later, black powder was being used as a weapon by Southern Wu troops at the siege of Yuzang. The age of black powder warfare had begun and would continue to rule the battlefield for almost a millennia.

How it Works

Potassium nitrate, which is represented chemically as KNO3, is a potent oxidizer that provides oxygen to the chemical reaction. Carbon, represented chemically as C, provides fuel. Sulfur, chemically represented as S, lowers ignition temperatures required for ignition.

When some form of external heat is added to the system, a chemical reaction is initiated. Simplified, the reaction looks something like this: 10 KNO3 + 8C+3S yields 2K2CO3 + 3K2SO4 + 6CO2 + 5N2. The resulting compounds, especially the resulting solids, highlight some of the weaknesses inherent to black powder as a propellant.

Unlike modern smokeless propellants, which convert almost completely to gas, black powder converts more than half of its mass into new solids. Only about 44 percent of the powder mass is converted into gases able to drive a projectile. The presence of this high molecular mass of solid residues is one of the reasons that muzzle velocities associated with black-powder firearms typically capstone at less than 2,000 feet per second (fps).

Black powder possesses a great advantage over smokeless propellants, at least in early firearm designs. Unlike smokeless propellants, black powder does not need to be ignited in a pressurized environment in order to reproduce. What this meant for early explosive manufacturers, small arms designers and cannoneers on medieval battlefields was that the ignition system could be as simple as a match. Smokeless powder will not work in a flintlock, for example, because the flash hole creates a pressure release valve that will not allow the propellant to propagate. Black powder, because it readily burns at one atmosphere of pressure, functions well in a flintlock’s open ignition system. With all its faults, black powder was a necessary stepping stone in the development of modern firearms.

How it’s Made

Qing Xuzi’s recipe for black powder has undergone some subtle modifications over the years, but the manufacturing processes have remained remarkably similar. The modern proportions for black powder have come to be standardized as a mixture of 75 percent potassium nitrate, 15 percent charcoal and 10 percent sulfur.

In the West, a dry-compounded powder called serpentine was commonly used as an early cannon propellant. It was made by grinding the individual components and then combining them as a loose powder. This fine powder tended to striate into its individual components during transportation and needed to be remixed before it was used. Because it was very finely grained and lacked the continuity of a homogeneous molecule, ignition characteristics were poor and sometimes dangerous. The process of corning offered more consistent ignition and pressures.

Corned powder was created by wet grinding the ingredients, which were then hand-shaped or pressed into molds to create individual grains of powder that resembled seeds of corn. Later iterations of this process used molds placed under pressure to create thin sheets of gunpowder slurry that were allowed to dry. Once dry, these cakes were broken up and then separated via a screening process to create homogenously-sized grains.

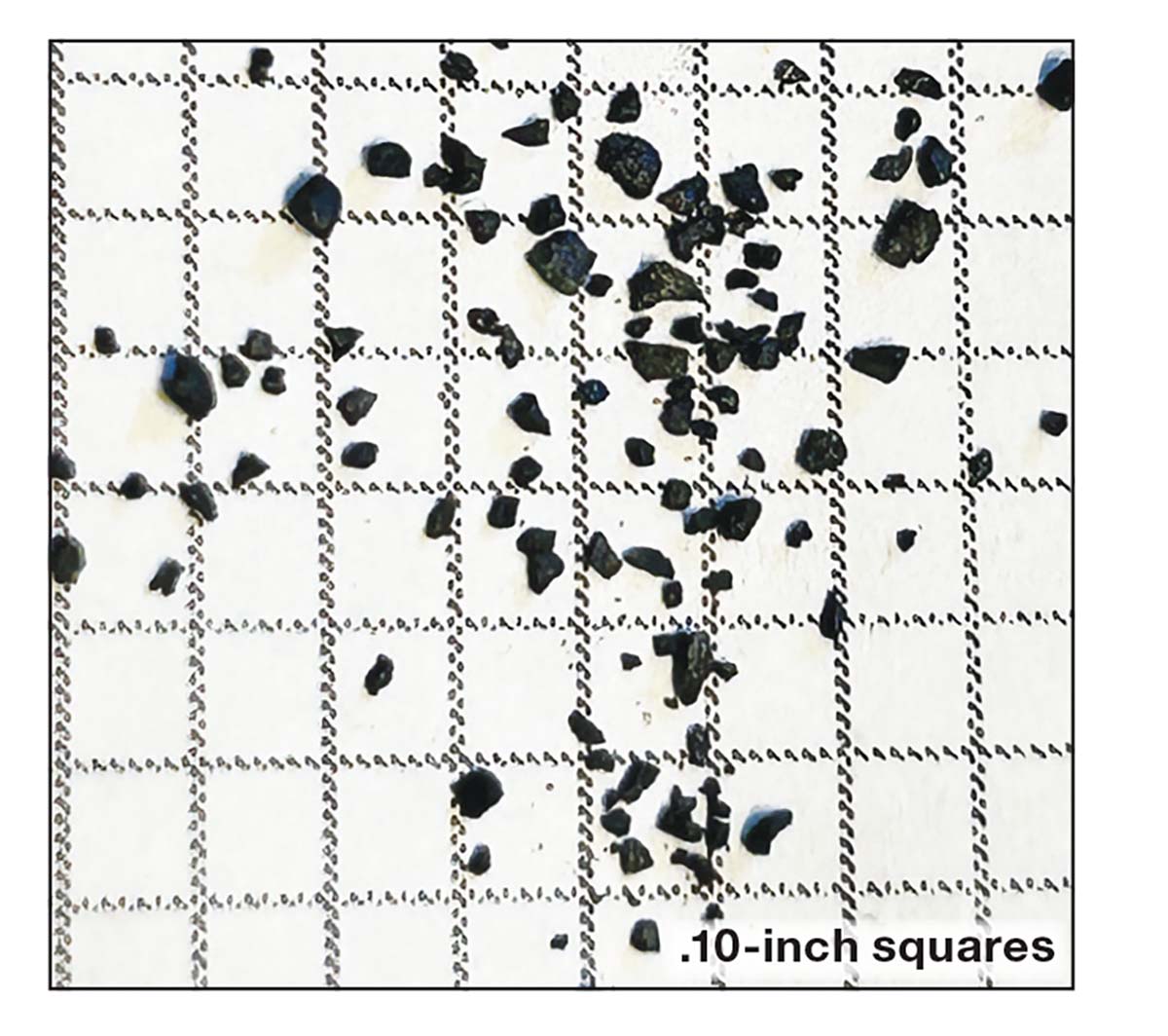

In black powder, the size and shape of the powder molecule is the primary driver of burn rates. Early ballisticians quickly realized that larger corns of powder worked better for cannons. The reason for this is that black powder is a degressive burner, which means the burn rate increases as the burning molecule grows smaller and is finally consumed. Larger grains took longer to burn, allowing the projectile to begin to move further down the bore before the propellant reached its maximum pressure. In small arms like muskets, finer grains were used to create pressure more rapidly.

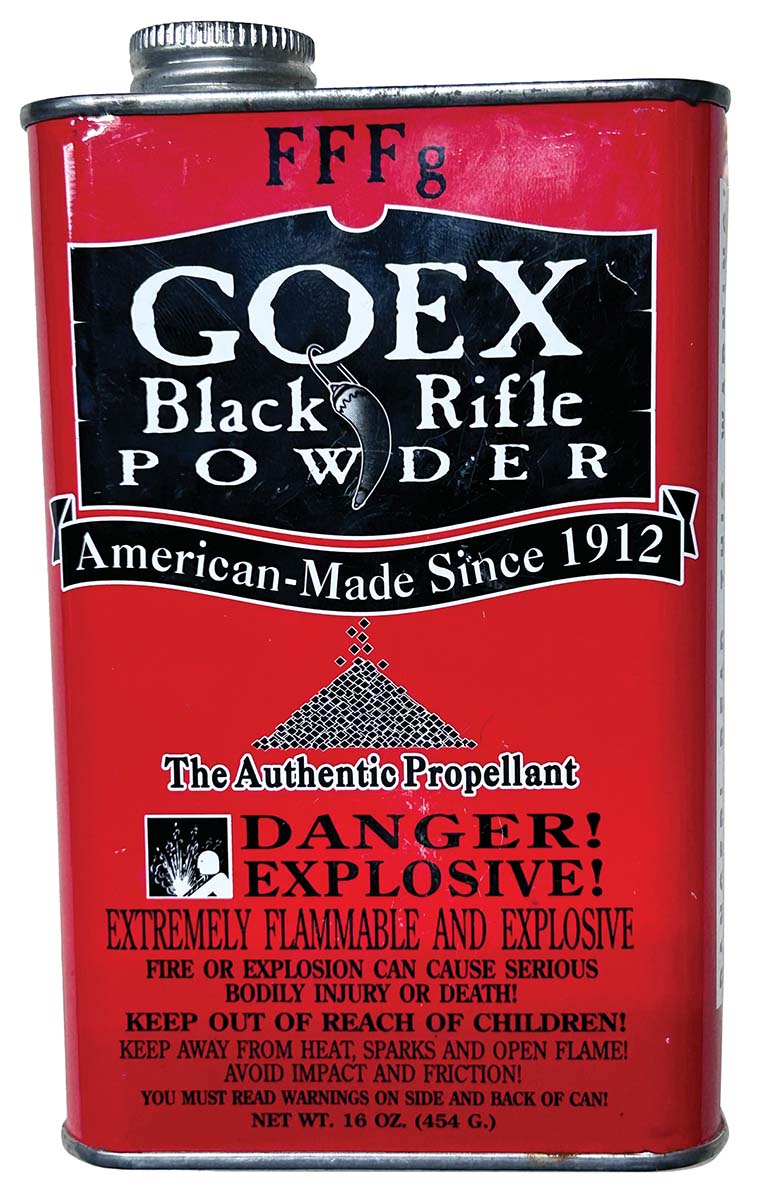

What do all the Fs Mean?

In modern production, black powder cakes are broken and then passed through progressively smaller screens to separate grains by size. These groups are sorted by their level of fineness, which is the “F” in sporting grade black powder. The largest sporting grade grain is Fg, which is commonly used in very large bore muskets and smaller cannons. As the grains become smaller, the number of Fs increase. FFg and FFFg are progressively finer and are the most commonly used grain sizes in sporting firearms. Because of its ease of ignition, FFFFg is commonly used as an initiator in flintlock powder pans. The “g” refers to a final manufacturing process where the individual grains are tumbled in graphite to provide a glazed surface and break away sharp edges. Whether the “g” stands for glazed or graphite depends on who is telling the story.

Next Issue

The development of smokeless propellants.