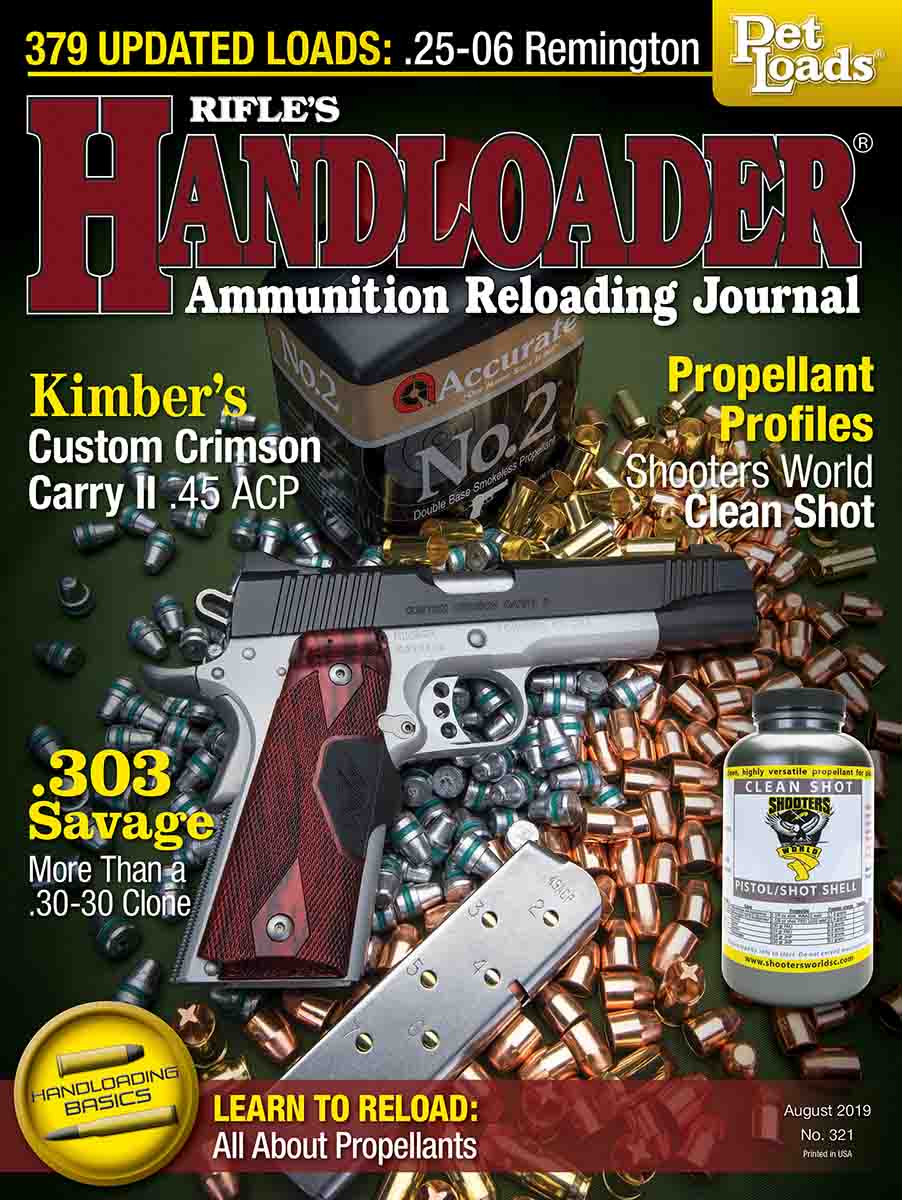

From The Hip

Kimber's Custom Crimson Carry II .45 ACP

column By: Brian Pearce | August, 19

However, in its original out-of-the-box “Government Model” configuration, it left room for improvement, with custom gunsmiths making careers modifying guns accordingly. Kimber recognized the need to offer custom features in production pistols as desired by shooters while improving quality, accuracy and reliability. Essentially, the goal was to offer a fully customized pistol that was ready to go right out of the box while keeping costs in check, which was accomplished by employing relatively new manufacturing technology.

Kimber’s first pistol was the Classic Custom .45 ACP, which remains in the product line today as the Custom II. I was forwarded one of the first produced, which was closely

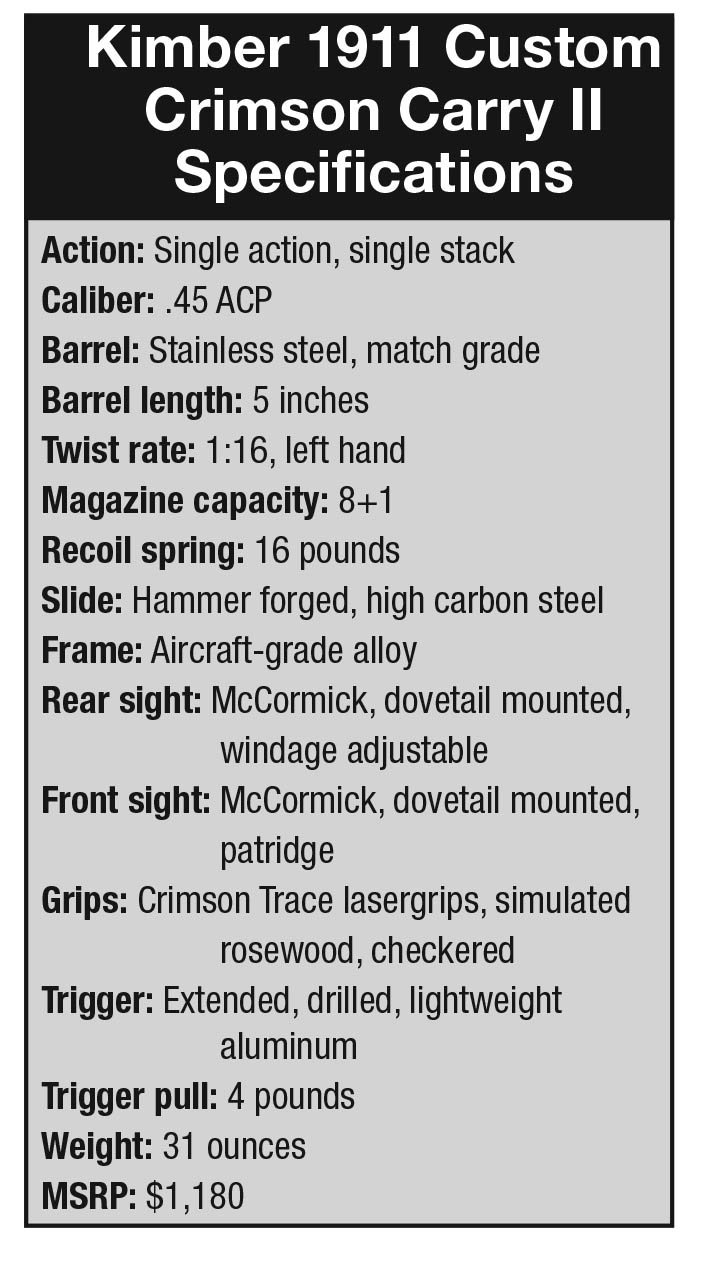

The slide assembly is hammer-forged carbon steel finished in matte blue, while the frame is in the white with a bead-blasted nonreflective finish to help reduce glare.

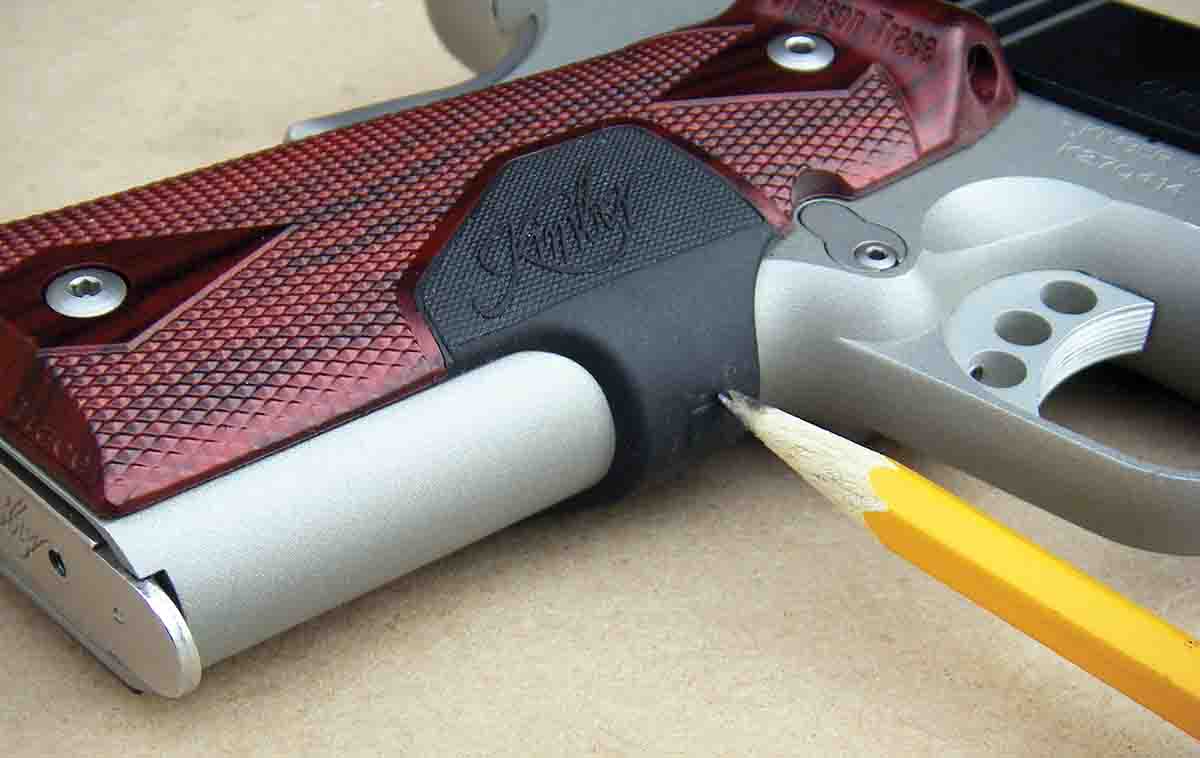

As its name implies, the grips are produced by Crimson Trace with a rosewood finish and a classic diamond checkering pattern. Combined with the two-tone pistol, it’s an attractive

As indicated, from the very beginning Kimber engineered its pistols to be ready to go right out of the box. For example, standard features included Chip McCormick front and rear sights dovetailed into the slide for increased durability.

The lightweight extended trigger is factory rated to break between 4 and 5 pounds, with the test pistol breaking cleanly at exactly 4 pounds. The slide stop and slightly extended magazine catch are knurled. The mainspring housing is flat, and the slide is slotted to assist the shooter’s grip. The high-quality springs are manufactured by Wolff Gunsprings. The barrel is match grade, while the ejection port is lowered and angled to further increase reliability.

These features (and many not mentioned) may not sound so outstanding today; however, when Kimber first began producing pistols, to have all of these features on a production Model 1911 was unheard of from a major manufacturer. Previously, custom pistolsmiths were retained to install similar features (along with improving accuracy and reliability), all of which cost significantly more. As a result of Kimber’s outstanding pistols, other manufacturers were forced to improve quality and increase features in order to compete.

Part of Kimber’s manufacturing process includes metal injection molding, or MIM. This permits major parts to be constructed of high-carbon steels, as well as stainless steel, at a comparatively modest cost while being held to very tight tolerances. While some gun designs and their small parts (especially revolvers) can be problematic with MIM parts, the major parts of the Model 1911 are perfectly suited to this process, resulting in a product that is tough and durable. Final machining of Kimber pistols is remarkable and results in

Over the years, I have used dozens of Kimber pistols rather extensively, and I am always impressed with the precise manner in which the slide and frame are fit, as well as the barrel, barrel bushing, linkage, etc., which results in outstanding accuracy. The Custom Crimson Carry II is no exception.

Beginning in 2001, Kimber introduced “Series II” pistols fitted with a Firing Pin Safety System located within the slide. It effectively blocks the firing pin from firing a cartridge in the unlikely event that the gun is dropped on a hard surface.

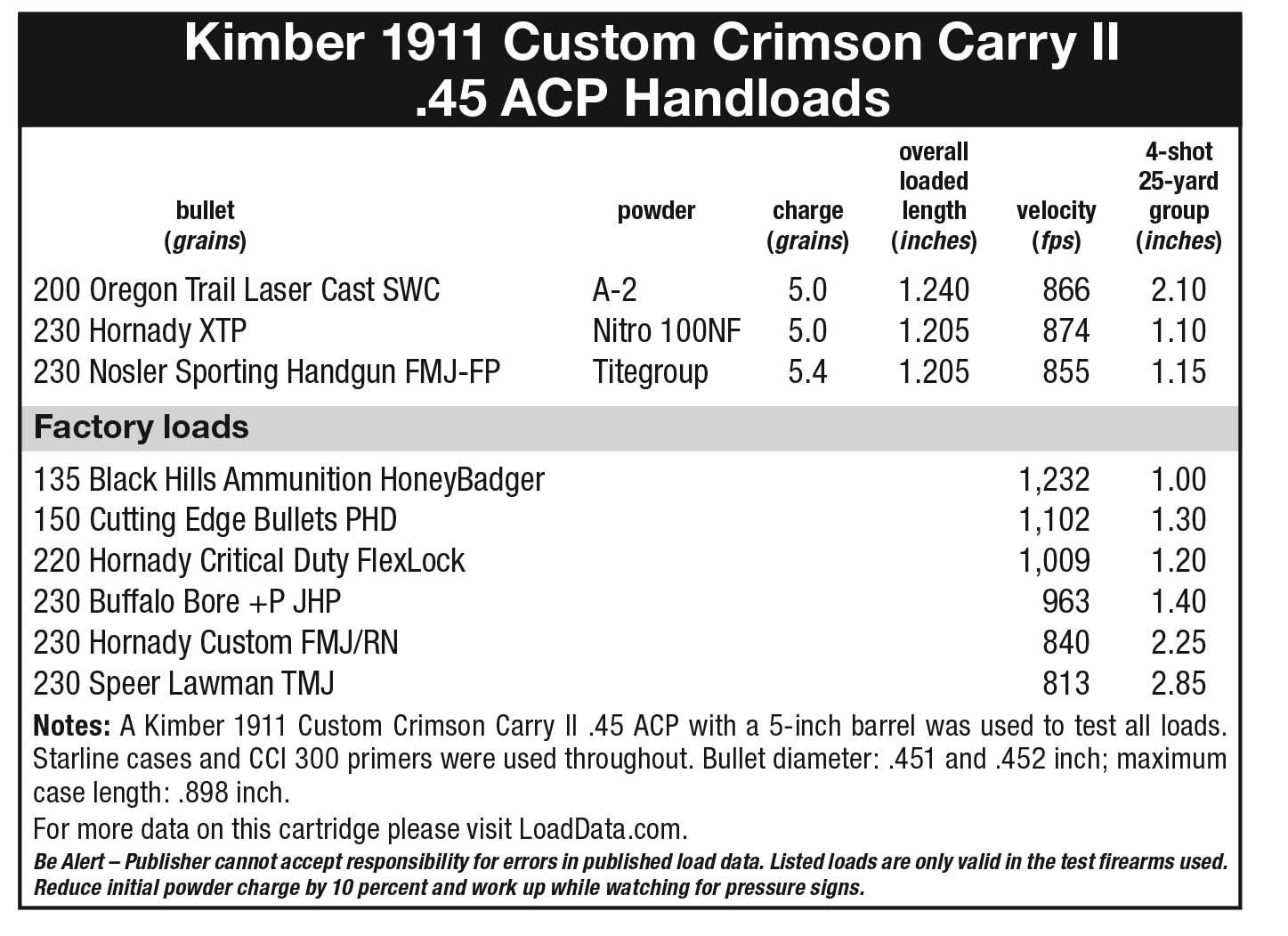

Initially, 200 rounds of Speer Lawman 230-grain TMJ (a roundnose ball-style cartridge) were fired through the new Custom Crimson Carry II to allow the gun to “settle” and break-in. It was then cleaned, lightly oiled and checked for velocity and accuracy using six factory loads. Notable performance came from Black Hills’ 135-grain Honey-Badger load, which features a solid copper bullet with a flat point and four large flutes cut into the ogive. This bullet offers a remarkable blend of tissue displacement and deep penetration. Muzzle velocity reached an impressive 1,232 fps which, with the bullet’s solid construction, also results in a high rating for barrier penetration. Accuracy was good, as select 25-yard groups hovered between 1.00 to 1.55 inches. Hornady’s Critical Duty 220-grain FlexLock reached 1,009 fps with groups measuring between 1.20 and 1.65 inches. Cutting Edge Bullets’ PHD 150-grain solid copper hollowpoint load recorded 1,102 fps and grouped between 1.30 to 1.70 inches. A more traditional load, but very proven, includes Buffalo Bore Ammunition’s 230-grain JHP that reached 963 fps and produced groups that ranged from 1.40 to 1.65 inches.

Using Hornady’s 230-grain XTP bullet, 5.0 grains of Accurate Nitro 100NF reached 874 fps and grouped four shots into 1.10 inches. With Nosler’s Sporting 230-grain FMJ-FP bullet pushed to 855 fps using 5.4 grains of Hodgdon Titegroup powder, the tightest group measured 1.15 inches. For a mild-recoiling target load, Oregon Trail’s 200-grain Laser Cast SWC bullet was pushed to 866 fps using 5.0 grains of Accurate No. 2 powder. Accuracy was respectable, with groups typically hovering between 2.10 to 2.65 inches.

Throughout testing, the Kimber Custom Crimson Carry II never failed to feed, fire, extract or eject cartridges and cases. It has proven to be reliable, accurate and ready-to-go right out of the box. The trigger is excellent and has the advantage of a crisp, clean pull with minimal take up and reset, all of which aids with accuracy and quick follow-up shots.

Kimber has earned the title of being the “world’s largest producer of 1911 pistols.” They are 100 percent manufactured in the U.S. and offer a custom level of accuracy and reliability, and they come standard with many desirable features.