Trophy Bonded Tip

The Reintroduction of a Prominent Bullet

feature By: John Barsness | April, 18

Among those hunters was Jack Carter, a guy who primarily wanted a tougher expanding bullet for African game such as Cape buffalo. His bullet featured a solid-shank copper jacket with a bonded lead core in the front end. After considerable testing in “media,” Carter did a field trial of Trophy Bonded Bear Claws in Africa in 1988, and they worked so well he started selling them to a limited number of customers. One of those customers was Montana gunsmith Dave Gentry, who proudly showed me a box of Bear Claws he had purchased for elk hunting, though he hadn’t fired any yet.

Not long afterward I met Jack Carter at the annual SHOT Show, and after a very interesting conversation he offered to ship me

This can happen with solid-shank bullets, probably because the lack of a softer lead core prevents them from swaging down easily to fit slightly undersized bores, or “bumping up” to fill slightly oversized bores. The pure copper also tended to foul barrels more than conventional gilding metal jackets, mild brass made of copper alloyed with 5 to 10 percent zinc. (At about the same time, a Utah hunter named Randy Brooks was encountering the same accuracy and fouling problems with an all-copper, hollowpoint design he called the Barnes X-Bullet.)

Still, Bear Claws worked so well on really big game that in the early 1990s Federal began offering them in factory ammunition, which sold so well Carter’s production couldn’t keep up. Federal started making Bear Claw bullets at its Minnesota factory, switching to what’s known as 95-5 gilding metal instead of pure copper. This allowed faster production and reduced bore fouling somewhat.

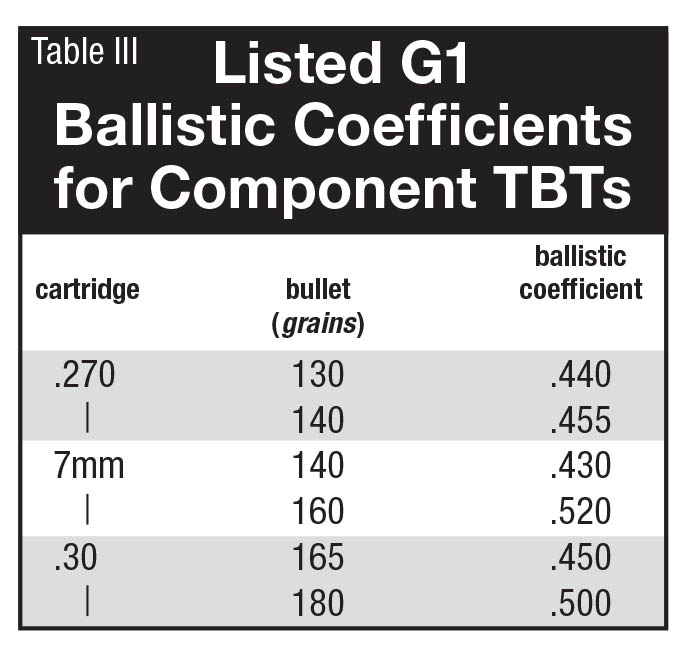

The Federal version, like the original, was designed specifically for larger game, so it often didn’t expand well on deer-size animals, especially at lower impact velocities, which often occurred at longer ranges. Bear Claw spitzers likewise had flat tips (much like Speer Grand Slams), resulting in mediocre ballistic coefficients (BCs). As an example, Federal listed the BC of the 180-grain, .30-caliber bullet as .368, while most pointed-tip 180s have BCs over .400 – sometimes well over.

One solution Federal tried was some of the first extra-velocity factory loads called High Energy.

Both my wife and I used the 180-grain High Energy Trophy Bonded loads in a New Ultra Light Arms .30-06. Velocity was listed at 2,880 fps, though in the NULA it chronographed around 2,950 fps, probably because of a tighter-than-average chamber. Accuracy averaged 1.25 inches for three-shot groups at 100 yards, sufficient for big game at “normal” ranges, and the higher velocity did help expansion on lighter animals. Eileen absolutely crumpled an average-size black bear with a typical lung shot at about 150 yards.

Some shooters believe plastic tips “wedge” deeply into the bullet, but high-speed video of bullets shot into clear ballistic gelatin shows the tips moving ahead of the bullet almost immediately after expansion begins, then drifting off to the side. The major reason for enhanced expansion is probably the big cavity required for the shank of the plastic tip.

The final touch was nickel-plating the gilding metal jacket, supposedly to prevent tarnishing. However, the thin nickel also decreased bore fouling – confirmed through my Hawkeye borescope – and combined with the translucent orange tip results in a very striking appearance.

Federal announced the Trophy Bonded Tip in 2008, and publicized the new bullet through field tests involving various firearms-industry people. I was one of the lucky people invited on an elk hunt on a ranch near my Montana home. The rifle used was a Benelli R1 semiautomatic .30-06, and the ammunition was Federal Premium loaded with 180-grain TBTs.

The hunt took place a month after the rut, when bulls have resolved their recent differences. We found a group of a half-dozen

The second bullet exited, but the first bullet did not. The temperature was warm for November, so we skinned the bull as soon as possible. I was hoping to find the first bullet under the hide, but did not, so guessed it ended up in the massive left shoulder. After taking the quarters home and allowing them to age and tenderize, my wife and I spent a day butchering the meat.

I sliced apart the left shoulder, searching thoroughly for the bullet, but never found it. This occasionally happens, sometimes because a premium bullet near the end of its travels often doesn’t leave an obvious hole in muscle. In the late 1990s I bit into a mule deer round steak, my teeth encountering what felt like a chunk of bone. Instead it was an expanded Nosler 140-grain Partition from my 7x57 that entered the buck’s chest and ended up in a hindquarter, where when slicing steaks my knife slid by on either side of the bullet. Unfortunately, the TBT bullet never reappeared.

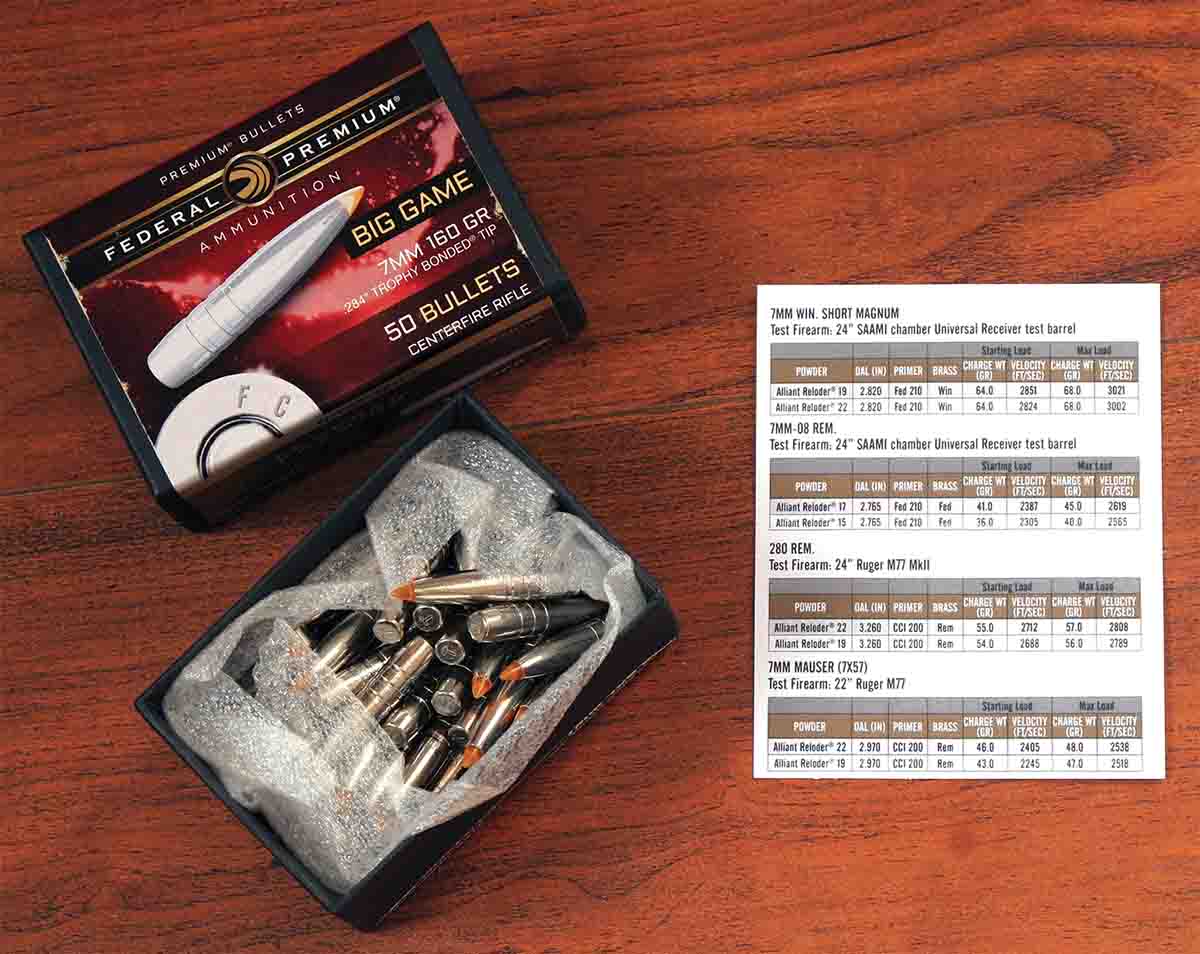

Federal planned to offer TBTs as component bullets, but reversed that decision within a few months, perhaps because Obama’s election increased demand for ammunition so much that selling loading components became impractical. It may not be a coincidence that Federal again decided to supply component TBTs during the first year of the Trump administration as demand for ammunition dropped.

The buck stood quartering toward me at 65 yards, and at the shot made the little leap typical of a solid chest shot, then trotted a ways before falling. The bullet cracked the scapula just above the shoulder joint and exited toward the rear of the ribs on the opposite side, leaving a big hole through both lungs.

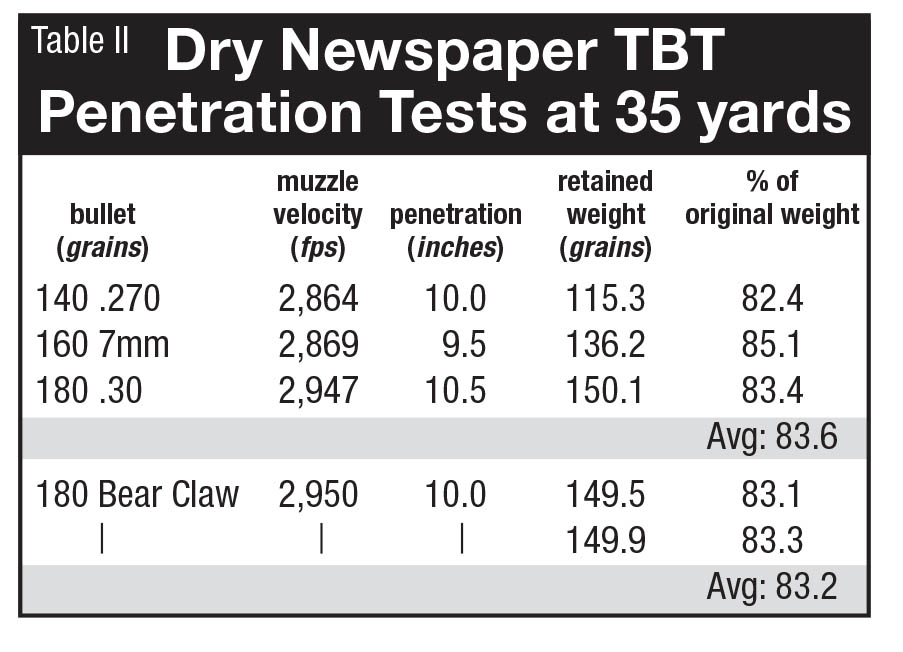

Some hunters have expressed concern that the TBT might expand too much, reducing penetration, so I shot the .270, 7mm and 180-grain .30 bullets into stacks of dry newspaper at 35 yards. Water-soaked newspaper is more commonly used as test media but is comparatively kind to big-game bullets, with even cup-and-core designs normally ending up perfectly mushroomed. Dry paper is much harder on bullets, providing a better simulation of striking heavy bone.

Shooting at 35 yards not only results in maximum stress on the bullet, but with rifles sighted-in a couple inches high at 100 is also about where the bullet’s path first coincides with the reticle. This makes it easy to precisely place several bullets in a single stack of paper.

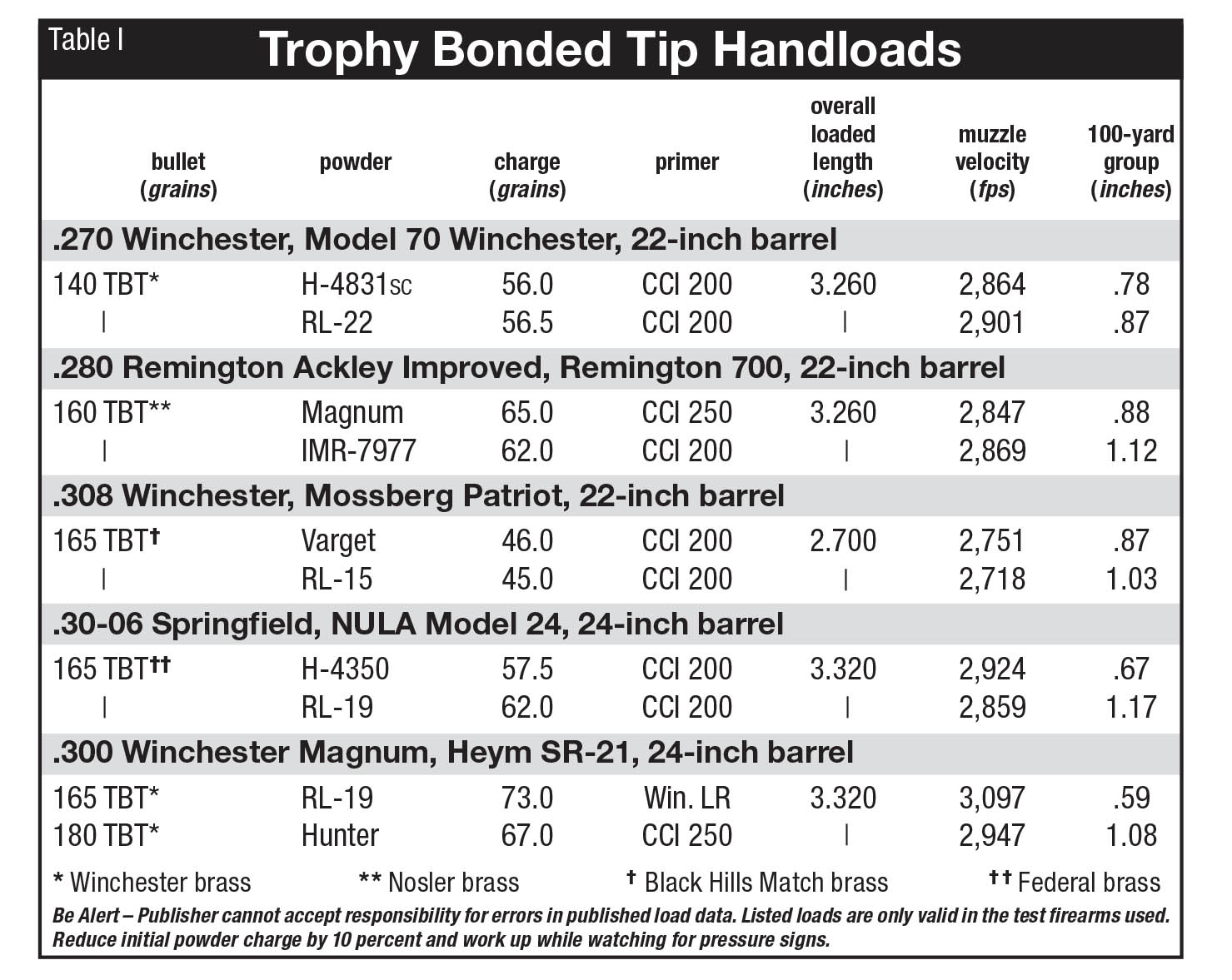

The results are listed in an accompanying table, along with the newspaper results from two High Energy 180-grain factory loads

Accuracy averaged much better than with the original Bear Claws. Mostly I used Federal’s loading data which, when compared to data for the same powders with other bullets, indicates the TBT develops more velocity (and hence pressure) than some other bullets. However, the 165-grain .308 Winchester load listed was worked up for the Mossberg Patriot before Federal listed Varget in its data. Several other sources list 45.0 to 46.0 grains as maximum for 165s in the .308, and in the Mossberg 46.0 grains shot most accurately without the slightest hint of excessive pressure, despite being two grains over Federal’s listed maximum.

Federal’s tables don’t include data for the .280 Ackley Improved, the largest 7mm cartridge chambered in any of my present rifles. So far in my hunting career, 7mm bullets at .280 AI velocities have never bounced off big-game animals, and over the last couple of years, somewhat subconsciously, I sold off all my 7mm magnums. (Of course, as a rifle loony I also reserve the right to acquire 7mm magnums in the future.) The two loads listed use charges of Ramshot Magnum and IMR-7977 which have previously proven accurate with other bullets in the 160-grain range.

The 73.0-grain charge of Reloder 19 used in the .300 Winchester Magnum is 1.5 grains less than Federal’s listed maximum, but 72 to 73 grains of RL-19 has shot extremely accurately with other 165s in several .300 Winchester Magnums. It proved to be very accurate with the 165-grain TBT as well. The Ramshot Hunter load with the 180-grain TBT was specifically designed to match the velocity of the High Energy 180-grain load from the NULA .30-06 for the penetration test, and it also shot well.

The higher BC of the TBT means it not only shoots flatter than the original Bear Claw, but it doesn’t need to be started fast to expand reliably on lighter game. The present 180-grain Trophy Bonded Tip .30-06 factory load is listed at the standard 2,700 fps muzzle velocity, yet according to the Sierra Infinity ballistic program shoots just about as flat as the 2,880 fps Bear Claw load out to 500 yards. It also arrives at 500 with about 250 fps more velocity, and it drifts 6 inches less in a 10-mph cross breeze.

The TBT looks to be a great addition to the premium big-game bullets available to handloaders. I’m already making plans to field- test some more.