Rifle Powder Temperature Sensitivity

Testing Modern Powders in Hot and Cold Conditions

feature By: John Barsness | December, 17

Early Cordite, the spaghetti-strand British “powder,” burned so much hotter in warm temperatures that factories often loaded ammunition with two different charges; one for shooting in the relatively cool climate of merry old England, and a “tropical” load with less powder for the warmer portions of the Empire. The heat sensitivity of early smokeless powders is also a primary reason for the considerable taper of many older rifle cases, easing extraction during hot weather. In cold weather, the same powders often “hang-fired,” with a pause between the click of the firing pin’s fall and the report.

Hodgdon introduced its Australian-made Hodgdon Extreme powders in the late 1990s, and today other “temperature-insensitive” powders appear every year. Target shooters were probably the first major customers, since temperature-insensitive powders eliminated a major variable, whether for short-range benchrest groups or long-range scores.

Hunters who regularly encountered real cold and heat also started using Hodgdon Extreme powders, but other hunters naturally questioned whether temperature-insensitive powders really made any difference. Many said they had used older powders like IMR-4350 in cold weather for decades and had never seen any difference. Some pointed out that a loss of 100 fps in muzzle velocity only makes an inch or two difference in trajectory at 400 yards. This is true as far as that goes, but other hunters did encounter significant differences in varying temperatures.

I started performing cold-weather experiments with various powders around 1990, prior to the introduction of the Extremes.

As an example, let’s use a typical .270 Winchester with a 150-grain spitzer at 2,900 fps, a common hunting handload in western Montana. When sighted in 2 inches high at 100 yards, the bullet lands about 6 inches low at 300 yards in typical fall hunting temperatures of 30 to 50 degrees. If muzzle velocity drops 100 fps at zero degrees, at 400 yards the bullet only lands about an inch lower, making no practical difference on a deer or elk.

However, that assumes there is no difference in point of impact (POI) at 100 yards. I soon discovered the 100-yard POI sometimes changed significantly in real cold conditions, and not just up and down, but sideways. Muzzle velocity also sometimes dropped closer to 200 fps.

At the time my .270 was a Remington Model 78, a less expensive version of the Model 700 with an uncheckered, “walnut-stained” stock. I had worked up two loads, one with the Nosler 130-grain Solid Base and Hodgdon’s original military surplus H-4831, and another using the 150-grain Partition with Alliant Reloder 22. At 70 degrees, a pair of three-shot groups at 100 yards with each load would group together into less than an inch. As a result, I could use the more “affordable” Solid Base for sighting in, practice and lighter big game, from doe whitetails to antelope on the plains, then switch to the Partition for elk in the western mountains without having to tweak the scope’s adjustments.

This anomaly convinced me to range test the pair of handloads on another cold morning. Both loads lost well over 100 fps, but for some reason the 130-grain load still landed in the same place as it had at 70 degrees (though it didn’t group nearly as well) while the 150-grain load shifted its POI 3 inches to the right. No wonder the Partition hit the shoulder instead of ribs! At 200 yards, POI would be 6 inches to the right.

Luckily the doe had been facing to the right, so other than losing some shoulder venison, no harm was done – though meat was obviously the primary reason for filling the antlerless tag. If the deer had been facing left, the bullet would have landed at the very rear of the lungs, and if the range had been longer it could have landed behind the chest cavity.

Since then I’ve tested any handloads that might be used in real cold by shooting in real cold. Sub-zero temperature can occur here from late October through late March, but most of my testing takes place in January and February, when the local weather forecast predicts overnight temperatures right around zero degrees. The evening before cold tests, I put the ammunition and cased rifles in my unheated garage. After starting my pickup the next day for the trip to the range, I load the ammunition and rifles in the back so they won’t heat up inside the cab. The chronograph stays inside the house until the cab warms up.

In 2017, January and February temperatures averaged well-below normal, so I was able to squeeze in three range sessions. Temperatures both at my house and reported on the local weather station ranged from -5 to 5 degrees throughout each test. Range testing at such temperatures sounds like it might be miserable, but often zero-degree temperatures occur during high-pressure systems, resulting in sunny skies and calm air. In the right clothing, it’s actually reasonably pleasant – though Barsness is a Norwegian name, so genetics could also be involved.

The one real trick is keeping the chronograph warm, because they don’t function very well much below freezing. In fact, I’ve

Rifles to be tested are carefully stored after their last warm-weather range session, so the scopes won’t get knocked out of zero and any change in POI can be checked. However, I admittedly don’t usually fire a bunch of groups at zero degrees. If one or two provide basically the same accuracy and velocity results as they did at 70 degrees, I feel confident in the load.

Most temperature experimenters chill only the ammunition, then range test it at “normal” temperatures. I’ve primarily tested outdoors in ambient cold, due to suspecting that shooting cold ammunition in a warm rifle might affect results. But during the past couple of years, some frozen-ammunition tests have been made just to be sure. I put the ammunition in a chest freezer set at zero degrees overnight, then transported it to the range in a frozen cooler with synthetic ice packs below and above the ammunition.

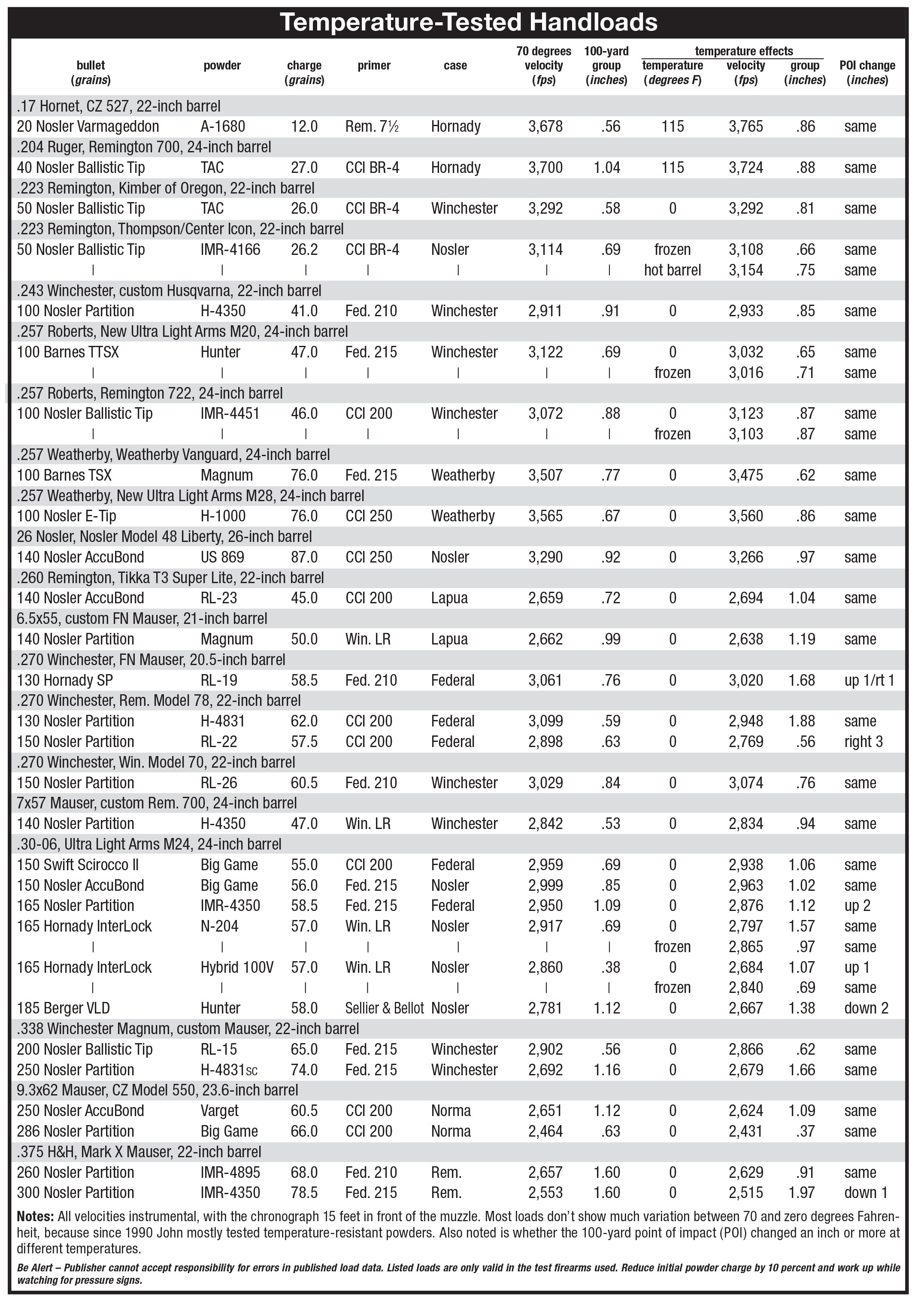

The results are included in the table, but it turns out my suspicion was correct. While some results have been essentially identical to shooting in actual cold, most have not.

Still, if ambient, cold-temperature testing isn’t possible, testing frozen ammunition is better than “guessing for the best.” (And no, freezing the rifle doesn’t work, because upon removal from the freezer all the metal instantly frosts up, and within a few minutes the frost melts into a thin layer of cold water. Neither is typical of subfreezing hunting.)

At home, I’m mostly concerned about cold but also often test ammunition on warm days, sometimes after “greenhousing” it inside a clear plastic bag with my small travel thermometer. The first such test occurred because of claims that early factory ammunition for the .416 Remington Magnum sometimes stuck in chambers during hot African hunting. Thanks to a reader named Pete Wilkinson, I obtained a box of early Remington ammunition loaded with the Swift 400-grain A-Frame and compared it to a recent box of the same load, doing the test shooting on a 95-degree August day with the ammunition warmed up to 110 degrees. Both boxes of ammunition chronographed similarly, with zero extraction problems, so I suspect most extraction problems in Africa have been due to dirty or rusty chambers, not temperature.

During a second range session, however, the bullets landed up to 6 inches apart at 50 yards. I soon realized the problem occurred because the ammunition had been sitting in the sun for a while, inside its translucent plastic box, and had warmed up considerably. After putting some rounds in the shade for a few minutes, they behaved perfectly.

This is one example of why I prefer the term “resistant” to “insensitive.” I’ve yet to find any powder that doesn’t gain some velocity at temperatures above 85 degrees, though with temperature-resistant powders the gain is much less than with conventional powders.

The one hot-weather situation frequently encountered in Montana is prairie dog shooting, where temperatures can reach more than 100 degrees. Some older powders popular among varmint shooters often do cause problems at hot, prairie dog temperatures, from stuck cases to blown primers, but I have yet to encounter either with newer, temperature-resistant powders.

After working up handloads for my two primary prairie dog rifles, a .17 Hornet and a .204 Ruger, I tested them by “greenhousing” a few rounds to 115 degrees. Accurate 1680 used in the .17-caliber load gained almost 100 fps in muzzle velocity but still shot to the same POI with similar accuracy and extracted easily.

Temperature resistance of a specific powder can also vary in different loads and cartridges. In Norma’s first 2004 edition of its hardcover manual, Sven-Eric Johansson of Nexplo/Bofors, the Scandinavian company that manufactures Norma powders, states: “For any caliber, rifle, bullet combination it is possible to engineer a powder that shows little pressure or velocity temperature dependency, but if loaded and shot from any other caliber, rifle, bullet combination, would likely exhibit a totally different temperature-behavior profile.”

One example of this is in the accompanying data for IMR-4350, where it shows far more cold resistance in the 300-grain load used in a Mark X .375 H&H, but not nearly as much in the NULA .30-06 with 165-grain bullets. Ramshot TAC also averaged exactly the same velocity at zero as it did at 70 degrees in the .223 Remington, but can it vary more in other cartridges. This isn’t surprising, since it was developed in Belgium for the 5.56x45 NATO, the military round that became the .223.

One of those “advanced” handloaders who owns a strain gauge for pressure testing got upset a couple of years ago after testing a load with H-4350 and finding the pressure curve varied at different temperatures. From this he claimed the Extreme powders are phony. Call me crazy, but I only care about muzzle velocity and POI changes. I’m also not concerned with velocity differences around 25 fps at different temperatures, because POI has never changed perceptively with such minor differences – and muzzle velocities often vary 25 fps when chronographing two strings of a given handload at the same temperature.

On the other hand, many rifles don’t always change 100-yard POI, even when muzzle velocity changes considerably. This is normal with heavier barrels but is also a tendency in sporters like the New Ultra Light Arms rifles used for some of the tests, due to the full-contact bedding in the forends of their stiff synthetic stocks. However, when rifles show considerable POI variation when trying different charges of the same powder during load work-up, they’re also prone to shifting 100-yard POI at different temperatures.

If primarily hunting in temperatures from around freezing to 85 degrees, common for the vast majority of hunting environments, you’ll probably never see much difference in muzzle velocity or POI with any modern rifle powder. All have apparently become much more temperature resistant in past decades, including some powders that were originally pretty sensitive. Though if you hunt in temperatures close to zero or above 85 degrees, working up handloads at around 70 degrees might not be sufficient, and the only way to know for sure is to shoot them at actual hunting temperatures.