Propellant Profiles

Shooters World Buffalo RIfle

column By: Randy Bimson | April, 21

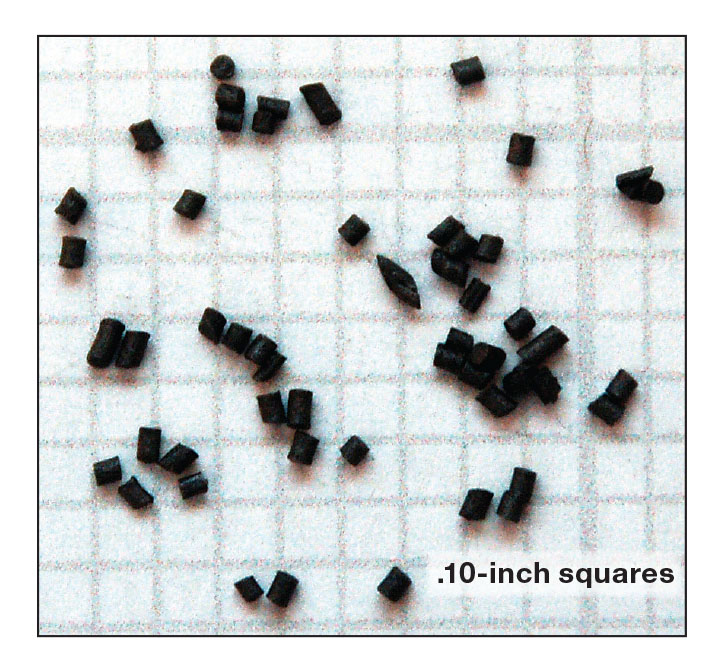

It is refreshing to see a company like Shooters World provide a propellant, Buffalo Rifle, tailored for loading these straight-wall-type rifle cartridges. Buffalo Rifle is a double base extruded propellant with a nitroglycerin content of 20 percent. It is one of the very “short cut” extruded propellants with the granules being a very nominal .055 inch length (more on that later) and a diameter of .036 inch. The bulk density of Buffalo Rifle is .87g/ cm3. and the grains are a dark gray color. The burn rate of Buffalo Rifle places it a little slower than H-110/Winchester 296, pretty comparable to Accurate 5744 and Alliant 300-AP, and a little faster than H-4198 and IMR-4198.

A secondary benefit of Buffalo Rifle is that its burn rate places it within the spectrum of propellants that work quite well for cast bullet and jacketed bullet reduced loads across a number of popular mainstream cartridges, such as the .30-06. While it does contain a flash suppressant, there are no burn rate modifiers or deterrent surface coatings used in the formulation of this propellant. The lack of such surface coatings is a good thing in this case, as it greatly facilitates more consistent ignition characteristics with the low loading densities associated with many cast bullet and reduced load jacketed bullet recipes.

Like other Shooters World propellants, Buffalo Rifle is sourced from the Explosia Company of the Czech Republic. Buffalo Rifle is marketed as Lovex D060 in Europe. The Shooters World and Explosia websites, along with LoadData.com, are good sources for loading data, with the Shooters World being the better for reduced and cast bullet data for mainstream cartridges.

Early on in discussing the characteristics of Buffalo Rifle propellant, I made mention that the grain length was .055 inch in length. What really surprised me was the extent of the variation, from .025 to .180 inch. In the interest of science, I dedicated an evening to measuring the length of 100 of those tiny grains of powder and creating an Excel spreadsheet to determine the “mode length,” or more simply the length that occurs most frequently in the data set. The mode length fell in the .050- to .060-inch range, 60 pieces; 23 pieces fell in the .020 to .049 range; 17 pieces fell between .098 and .180 inch in length. As the surface area of the individual grains of powder is a major contributor to the burn rate of a propellant, I was interested to see how it would affect the consistency of my test loads.

With my tried-and-true Neil Jones Custom Products powder dispenser set to throw a charge of 30 grains, 50 charges were thrown. The extreme spread was a low of 30.1 grains and a high of 30.5, a variation of four-tenths of a grain. I was very surprised when the 16th, 20th and 50th charges bridged, not dropping the entire charge into the scale pan, and required a double tap of the handle to clear the “logjam.” I have three different internal diameter drop tubes for the Neil Jones and the bridging occurred using the .223-inch diameter small tube, which works fine with propellants like IMR-4227 and IMR-4198. I considered the possibility the .180-inch-long grains encountered in Buffalo Rifle may periodically align in such a way as to cause a “logjam” effect in the smallest diameter drop tube.

I switched to the large drop tube, which has a .265-inch internal diameter. I threw another 50 charges without any hint of bridging. Just something to be aware of if, like many powder dispensers, your powder dispenser has interchangeable drop tubes with different interior diameters.

For propellant application, I focused on three cartridges. The .38-55 and .45-70 being representative of the straight-walled cartridge cases, both with cast bullet loads, and the .30-06 being representative of a mainstream cartridge using greatly reduced jacketed bullet loads. A nice clean tang-sighted pre-64 Winchester Model 94 with a 24-inch barrel was the test bed for the .38-55, a 28-inch heavy-barrel Lyman Centennial Ruger No. 1 for the .45-70 and in .30-06 a Sako 85 with a 24-inch Shilen barrel.

The Ruger No. 1, outfitted with a Kepplinger single-set trigger, is a very fine shooter. The benchmark load that all other loads have to live up to is Winchester cases primed with Winchester Large Rifle primers and 16.5 grains of Unique behind a half-grain tuft of Dacron wading, and the 420-grain Lyman 457193 cast bullet. Off the bench, this low-recoil combination consistently shoots 1.125-inch, five-shot groups at 100 yards.

The Ruger took a shine to the Buffalo Rifle propellant, regularly delivering five-shot, 100-yard groups just over 1.375 inches, center to center, with 24 grains of Buffalo Rifle behind the same 420-grain cast bullet. What a pleasant load to shoot! The velocity was 1,235 fps, somewhat slower than I anticipated from the 28-inch barrel, but given the fast burn rate of Buffalo Rifle, I likely ran out of peak barrel pressure and was on the downward plunge long before running out of barrel.

The .38-55 Model 94 took more work with Buffalo Rifle. I had to run the gamut from 18 to 24 grains in .5-grain increments to find the sweet spot of 23.5 grains behind a 235-grain cast bullet dropped from a fine SAECO mould. Using the tang sight, five-shot groups averaged 2.5 inches off the bench at 100 yards.

The .30-06 loads were an experiment to see how a reduced load listed in the Shooters World reloading data, 10 grains of Buffalo Rifle behind the 125-grain Sierra bullet tucked into Jagemann unfired cases, would perform. Accuracy was more than acceptable, with five-shot groups running just a hair over an inch off the bench at 100 yards. At 1,195 fps, the average velocity of a Shilen-barreled Sako aligned very well with Shooters World’s SAAMI pressure test barrel data. Given the extremely low load density to case volume, I was very interested to see what kind of variation powder-to-primer and powder-to-bullet orientation would have on the velocity. The deviation between the average of five rounds each of powder-to-primer and powder-to-bullet was 89 fps. Something that one has to concede is that with greatly reduced loads the propellant is not working within its optimum range and hence, it does burn dirty. At 700 .30-06 rounds to the pound, handloaders are getting a lot of bang for the buck. A little more cleaning is a fair trade-off for an economical load that can literally be shot all day in comfort and performs well at 100- to 150-yard ranges.

I think for anyone who shoots the medium- to large-bore, straight-walled cartridges and also has a need for economical reduced loads for more mainstream cartridges, Buffalo Rifle is worthy of spending your hard-earned dollars.

.jpg)