Shell Shock Technologies

Testing the New 9mm Nickel Alloy Shell (NAS3)

feature By: John Haviland | February, 20

Brass has been the metal of choice for cartridge cases since nearly the advent of self-contained cartridges. Copper, the main component of brass, though, is a relatively expensive metal. Cases constructed of aluminum or steel, or partially of polymer, are used to lower costs but are not reloadable. A few years ago, Shell Shock Technologies started making Nickel Alloy Shell (NAS3) 9mm Luger cases with a nickel-plated aluminum head connected to a nickel-steel alloy body that are reloadable.

Shell Shock indicated the head of NAS3 cases will not wear out or balloon when fired in an unsupported chamber, and the body is self-lubricating, corrosion resistant with twice the tensile strength, and yet it’s more elastic than brass cases. NAS3 cases also weigh about half and cost half to a third of the price of regular brass cases.

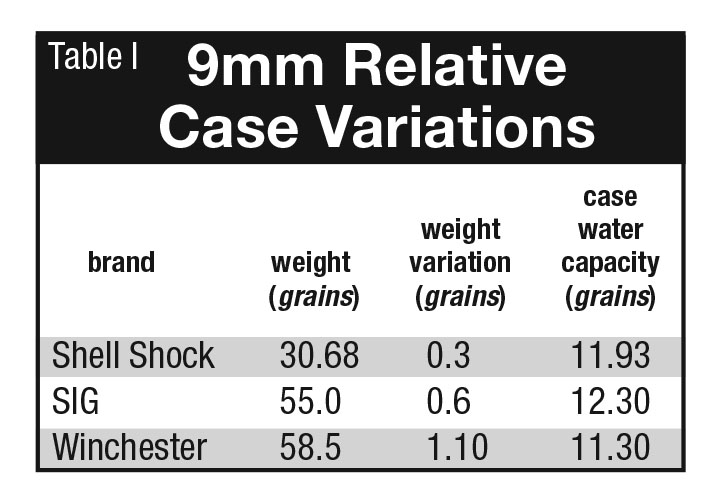

I compared NAS3 cases to SIG and Winchester 9mm brass cases. The web of NAS3 cases is slightly higher than regular brass 9mm cases. This is due to the construction of the cases with a flange on the bottom of the body swaged onto the aluminum head of the case to lock the two together. That should translate into less internal capacity for NAS3 cases compared to regular brass cases. Shell Shock states the cases have a one- to 2-percent larger internal volume than brass cases. However, NAS3 and regular brass cases were similar in capacity. The average weight, weight variation and water capacity of 10 each of three brands of cases are listed in Table 1.

Case mouth wall thickness was the same .012 inch for NAS3, SIG and Winchester 9mm cases. As deep as the jaws of my caliper could reach into cases, the wall thickness of NAS3 cases measured .015 inch, Winchester measured .023 inch and SIG .018 inch.

NAS3 cases have a cone-shaped and slightly larger flash hole than brass cases. Shell Shock says this “eliminates back-face pressure” and enables more hot metal particles from lead-free primers to ignite powder. Near as I can measure, the flash hole of NAS3 cases is .0860 inch in diameter, which is about .01 inch larger than a standard small pistol primer flash hole.

A regular sizing die and flaring die, which require withdrawing cases from the dies with the downward pressure of a press handle, might ruin the aluminum rim and partially or fully pull apart two-piece NAS3 cases. S3 Reload (s3reload.com) sells a special sizing/decapping die and mouth expander die for $80 that incorporate a polymer spring to push NAS3 cases out of the dies without damage.

The S3 Reload sizing die includes a carbide sizing ring. However, cases must still be lubricated to eject from the die. Setting up the die requires unthreading a cap screw to release pressure on the spring, turning the die into a press until it contacts the raised shell holder, raising the die a quarter turn from touching the shell holder, turning down the lock ring against the press and locking the ring with the brass set screw. The cap screw is threaded back into the die until it touches the spring.

The expander die is adjusted by unthreading the cap screw to release pressure on the spring so the pusher rod moves freely inside the die. The die is screwed into the press until the expander plug touches a sized case raised to the top of the press stroke, and the cap screw is threaded in until it touches the spring. Lowering the case, turning in the die and raising the case to check for mouth expansion is repeated until the case receives the proper amount of flare. The lock ring is set against the press and the set screw is tightened.

At least a dozen ammunition companies use NAS3 cases to manufacture 9mm Luger cartridges. I sized most of 100 NAS3 cases that had been loaded in L-Tech Enterprises 9mm Luger cartridges. The sizing die spring made a sharp “clank” when pushing out a case. The flaring die made less of a “clank” pushing cases off its expander. Fired cases stretched only .001 inch when sized in the S3 Reload sizing die.

The S3 Reload sizing and flaring dies can be used with regular brass cases. However, the springs in the dies made no noise when regular brass 9mm cases were removed from the dies. That was because the pusher rod in the dies did not contact the shallower web in brass 9mm cases, and cases were pulled out of the die by the force of the lowering press ram.

According to Shell Shock, “The bullets will only require a light crimp; the nickel alloy used in our case cylinder has a much higher tensile strength than brass and does not require the bullet to be seated as deeply or crimped as hard as brass.” A regular seating die seats bullets and applies a taper crimp to NAS3 cases. I seated bullets with a Redding 9mm Luger seating die with the body turned into the press to remove the flare on case mouths and apply a slight taper crimp so finished cartridges had a mouth rim diameter of .380 inch. That die setting applied the same amount of a taper crimp to brass cases.

For a comparison, I handloaded NAS3 and brass SIG and Winchester 9mm Luger cases with Speer 115-grain TMJ RN bullets and Blue Dot and Power Pistol powders. The loads were shot through a SIG Sauer SP2022 with a 3.9-inch barrel and a SIG Sauer Legion P320 XFive with a 5-inch barrel. Shell Shock cases loaded with Blue Dot fired the Speer bullets about 40 fps faster than the same load in SIG and Winchester cases shot from the SP2022. Shell Shock cases with the same load developed about 30 fps less velocity than the SIG and Winchester cases when fired from the Legion P320. Shell Shock cases generated about 10 fps more velocity than SIG and Winchester cases loaded with the Power Pistol/Speer load fired through the SP2022, and 50 fps faster when shot through the Legion P320.

Extreme velocity spread for the Blue Dot load was 48 fps for NAS3 cases, 85 fps for SIG cases and 43 fps for Winchester cases fired from the SP2022. The Blue Dot load’s extreme velocity spread was 76 fps for NAS3 cases, 35 fps in SIG cases and 52 fps for Winchester cases fired from the P320. Fired from the SP2022, greatest spread of velocity for the Power Pistol load was 60 fps from NAS3 cases, 37 fps from SIG cases and 24 fps from Winchester cases. Maximum velocity spread for the Power Pistol load shot from the Legion was 18 fps with NAS3 cases, 19 fps for SIG and 17 fps with Winchester cases.

Boiled down, all these numbers show there was not much difference between the three case brands. Total extreme velocity spread from all loads using NAS3 cases averaged 40 fps for the SIG SP2022 pistol and 30 fps for the SIG Legion.

Shell Shock indicates NAS3 cases are two times stronger and more elastic than brass and will not split, chip or crack. Handgun cases eventually fail when they split at the mouth from repeated flaring and crimping. The mouth of one case remained intact after flaring and crimping 15 times, about the time when my fingers cramped from handling the pint-size cases. For me, cases ejected from autoloading pistols are lost long before they split. That is no great loss considering such inexpensive 9mm cases.

Shell Shock’s website, shellshocktechnologies.com, sells 500 9mm NAS3 cases for $60 and 1,000 for $100. A click to connect with the portal to the universe shows brass 9mm cases cost from twelve to thirty-three cents apiece.

Plans have been in the works for a couple of years for Shell Shock to produce NAS3 cases for other handgun cartridges and the .223 Remington. So far only 9mms are available. Perhaps this is because handloaders are set in their ways and slow to adopt a new product that replaces brass, which has worked so well for over a century.

No problems arose while handloading several hundred cartridges utilizing Shell Shock NAS3 cases, and the two SIG 9mm pistols never hiccupped once while shooting them. Some of the loads were on the mild side and powder fouling caked the cases. Forty minutes in a vibrating tumbler with ground walnut shells cleaned the cases bright and shiny, inside and out. Replacing standard 9mm Luger dies with the $80 S3 Reload sizing and flaring dies is the only drawback to NAS3 cases. The low price of Shell Shock cases will eventually pay for the dies, and no doubt Shell Shock cases can be loaded many, many times to further stretch your handloading dollar.