Oehler's New System 89 Chronograph

Measuring Bullet Performance Downrange

feature By: Rick Jamison | June, 22

“Time of bullet flight is everything.” Those are the words of Ken Oehler, inventor, developer, producer and supplier of test systems for the entire shooting industry – private, commercial, industrial and governmental. If the piece is handheld, shoulder-fired, or if the projectile comes from artillery or a tank, an Oehler system can measure the performance. In the field of ballistics measurement, Ken knows whereof he speaks. An accurate flight time is the key for velocity, energy, drop and wind deflection – everything, just as Ken said.

The reality is that when we chronograph a bullet, we are already measuring time of flight over a very short distance, the distance of the chronograph screen spacing. Time of flight is then mathematically/electronically converted to velocity.

Heretofore, handloaders have been unable to measure time of flight over great distances to get meaningful ballistic coefficients. As a result, downrange predictions have significant errors. The greater the distance, the greater the effect of those errors. Now this handicap is history. As with chronographs, the genius of Ken Oehler provides the means to measure with the System 89.

The crux of the new system is a multiplex of downrange microphones to pick up the shock wave of a passing bullet. This is combined with the magical synchronization of time and electronic communication between two radios. One radio is placed near the firing point and the other is downrange near the target, as much as two miles away!

Near the rifle is a conventional chronograph SkyScreen setup. The screen wires are connected to the nearby radio on a small tripod, and the radio is connected to a laptop computer on or near the shooting bench or firing point. A bullet passing through the start screen triggers a clock to first pickup velocity near the muzzle as normal, but the clock continues to run on the bullet traveling downrange. Microphones near the target then record the time elapsed since the bullet triggered the chronograph start screen. The information is relayed by a second radio placed downrange back to the gun radio and computer. This time of flight is then used to calculate an accurate ballistic coefficient over the distance traveled.

This is incredible enough, but the System 89 does far more. Typically, four microphones can be assembled downrange with three, 40-inch sections of 3/4-inch PVC pipe to space the mics equally into a 10-foot wide bar laid horizontally on the ground. Simply shoot over the bar and all four microphones pick up the passing bullet. Not only do they pick it up for time of flight but acting in concert (synchronized for time) the mics then triangulate the position of the bullet when it passes. If more exact triangulation is required, PVC pipe can be arranged in a square with mics in the corners and the frame positioned vertically so that bullets pass through. I have used only the linear bar called a “Fly-Over Target.” It is much easier to set up without the necessity of vertical supports and it works well.

.jpg)

.jpg)

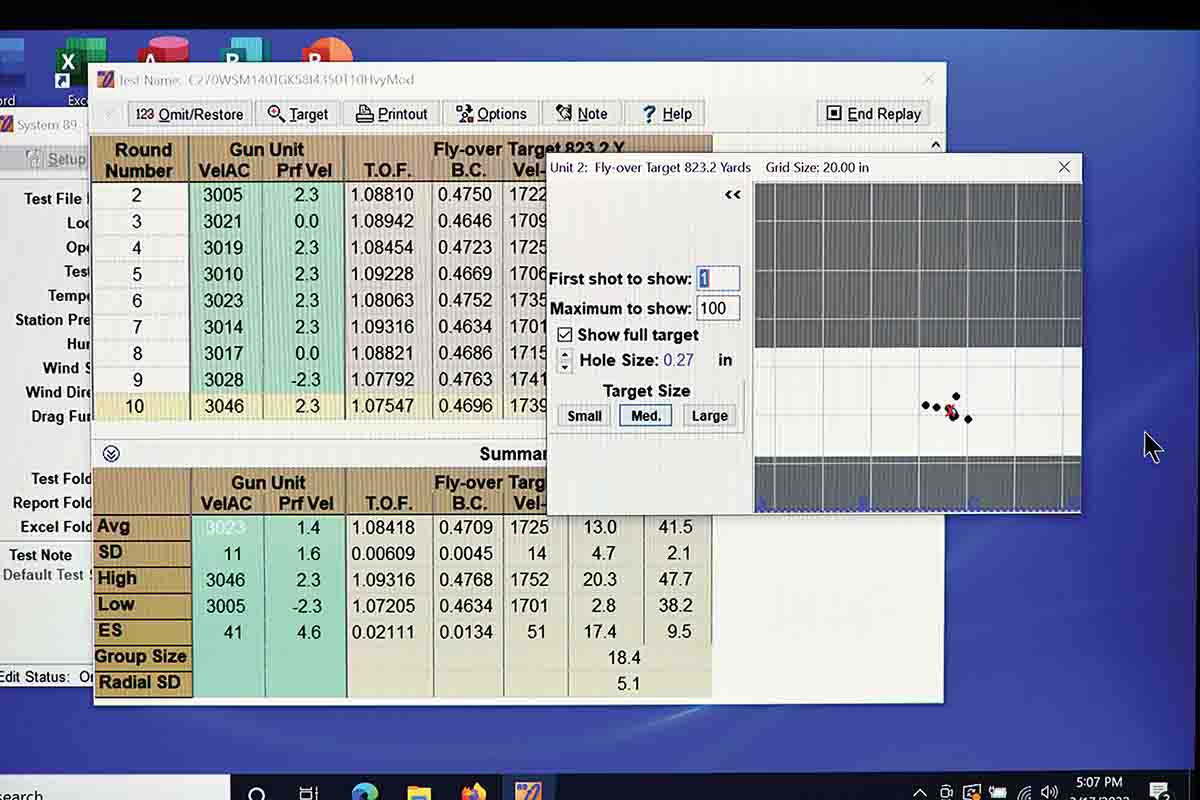

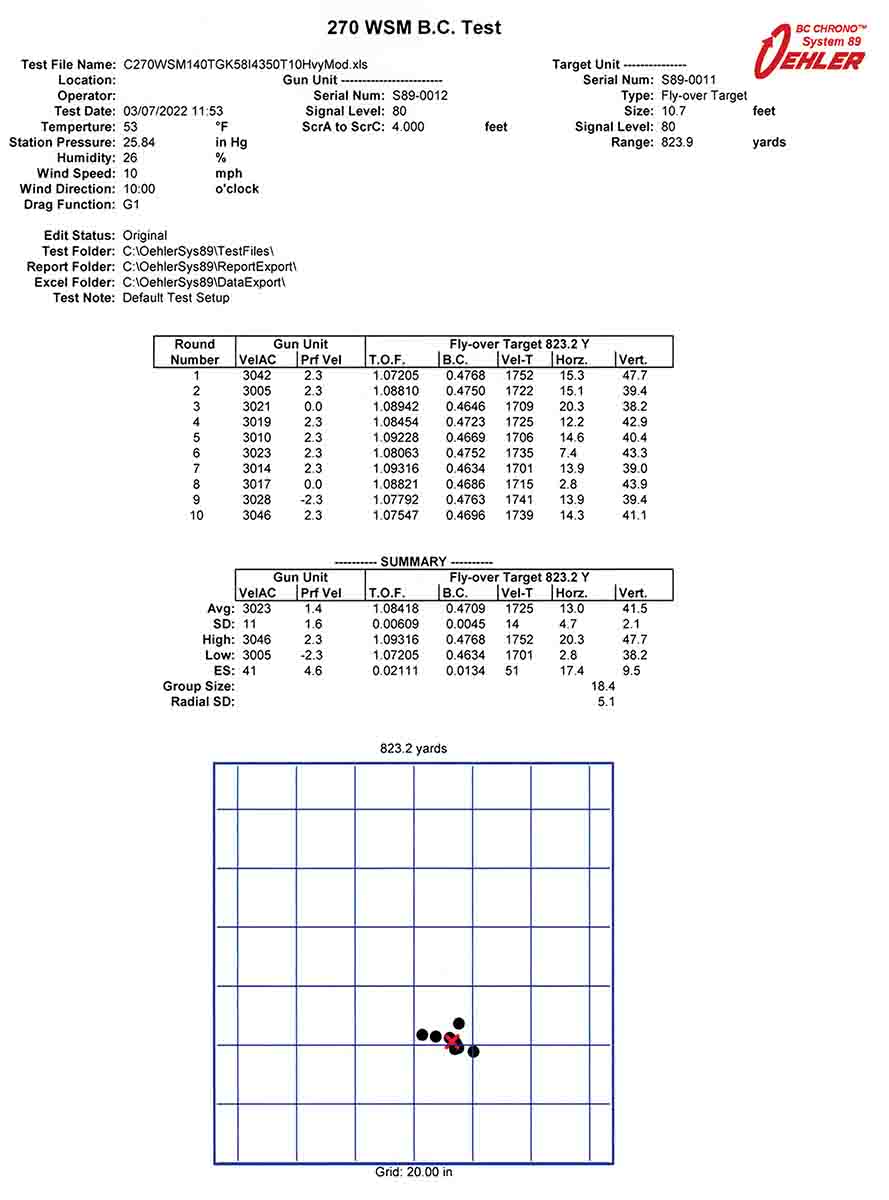

The System 89 is not designed for measuring groups, but for time of flight and ballistic coefficient determination, though it does report group size. If at a later time, a person wants to know which data set belongs with which “bullet hole,” just click on the bullet hole and it will be highlighted. The corresponding data set will also be highlighted. Conversely, A shooter can click on a row of data to highlight it and the corresponding bullet hole will be highlighted. So if you have a bullet out of the group, for example, and want to see if there was something different about it, you can easily identify and examine the corresponding data.

If you shoot so far that your bullets become subsonic, or if you’re shooting a handgun or .22 rimfire that does not produce a shock wave, the System 89 accommodates. Simply C-clamp a microphone or two to the corner of a piece of half-inch plywood, chipboard or wall board and shoot through the material. With such an impact target, you get all the numbers except group size, even on subsonic .22 rimfire ammunition or an air rifle.

Whatever the target choice, the microphones are connected by wire to the small radio unit on a lightweight, collapsible tripod well to the side of the target area. For a downrange setup, that’s all there is! Simple. Oh yes, you might want to put up a paper target just to have an aiming point.

You need not be on a measured range, nor do you have to shoot at a set distance, but whatever the distance is, it must be accurately measured. How do you do that? For about $500, Oehler supplies a Leupold rangefinder specially calibrated and modified with a narrower laser beam that measures to the tenth of a yard! There is laser-reflective paper that can be taped to the side of each radio. One radio is placed downrange abreast of the microphone setup and the other one near the firing point abreast of the chronograph start SkyScreen.

I grey-taped the Leupold rangefinder to the head of a sturdy tripod for stability. Then from a sitting position with elbows on my knees and aiming at the distant laser reflective paper, the Leupold’s laser locks onto the target. Repeated measurements yield repeated results.

While the layout is simple, it is important to make several precise measurements for BC testing. The PVC pipe has joints at the microphones and is put together each time the unit is set up. The distance between centers of the widest (or end) microphones must be measured on the linear array. SkyScreen measurements need to be right-on. The distance from the start SkyScreen to the target must be verified and to double-check, the distance from the target to the start SkyScreen is also taken. Once this measurement is verified, the near radio can be placed to the side and rear of the firearm’s muzzle to avoid blast.

A shooter also needs a means to gauge ambient conditions. The popular handheld Kestrel units work fine and there is no need to purchase the expensive ones designated for ballistics. The simpler and less costly Model 3500 provides all the data necessary.

Even if a shooter measures time of flight to derive a specific ballistic coefficient value, G1, G7, or any other with the System 89 at a specific distance, they do not know if this drag function describes the bullet’s complete flight path as closely as desired. Some drag functions will be close and others not. You have no doubt heard about renowned shooter and ballistician Bryan Litz’s books on this subject. Probably because of his knowledge and writing, some bullet companies no longer report only G1 figures but G7 as well. It turns out that while we have been using the G1 for many years, the G7 in general more closely predicts the path of today’s bullets.

How does a shooter know which drag function most accurately describes and predicts the bullet’s flight path? The System 89 can tell. Buford Boone, retired supervisory agent of the FBI ballistic research facility, explained to me that it can be done by shooting for BC at two distances. The drag function that produces the closest values at the two distances is the one that most closely matches the bullet’s path. Yet another amazing feature of the Oehler system is that different drag functions can be applied even after data is shot!

Friend J.T. Parr and I recently did this with the .277 diameter Hornady 130-grain SST and the Speer 130-grain flatbase bullets, two drastically different shapes. The bullets were fired in 10-shot strings at 256 and 823.9 yards, initially using G1. I then ran all the drag functions in the Oehler System 89 program (there are 10 of them) to see which BC numbers matched most closely at the two distances.

.jpg)

The system offers a decided advantage to a long-range competitive shooter evaluating load uniformity over distance. It is also a great training tool. Just being able to see immediately what a current wind is worth for every shot will do wonders for anyone’s shooting. It is better than having a spotter and the shooter does not have to go downrange to see a bullet hole. It is right in front of their eyes!

There are so many practical advantages to using this new system. It can answer all sorts of questions about your handloads. For example, bullets are ever longer in a given weight with higher ballistic coefficients. They have become so long that I wondered whether some might be more stable in flight if fired from a quicker than standard rifling twist. For example, an earlier .277 diameter 150-grain bullet, the lead-tipped Speer flatbase spitzer is 1.177 inches long. The newer ultra-streamlined Nosler 150-grain AccuBond LR boat-tail is 1.425 inches long. Nothing like such a long bullet was around when the 10-twist was standardized for this diameter.

I have .270 WSM rifles with the old standard 1:10 twist and I have rifles with quicker 1:9 and 1:8 twists in this caliber. With the System 89, it was a natural to fire the new long bullets from both a standard 1:10 twist and a quicker 1:8 twist to compare. I shot the streamlined Berger 150-grain VLD and the ultra-long Nosler 150-grain AccuBond LR. Nosler has more recently introduced an even heavier 165-grain .277 AccuBond LR bullet, but it comes recommended for a minimum 1:9 twist. Its 150-grain bullet carries no such indication.

I fired 10-shot strings of both bullets in both twists at 823.9 yards and compared. Indeed, there was a BC improvement for both bullets when fired from the 1:8 twist barrel. The Nosler went from a G1 .560 BC in the 1:10 twist to a .572 BC in the 1:8 twist. The Berger went from a .533 BC to a .545 BC in the 1:8 twist for a 10-shot average at that distance.

My initial reaction was that the 1:8 twist better stabilized these long bullets. Time-of-flight does not lie, but my initial interpretation could be mistaken. The differing results could be from using different barrels irrespective of twist, just as with velocity. The 1:10 twist was a well-used Shilen and the 1:8 twist was an almost-new Schneider. See the details in Table III.

I can see from the extreme spreads in ballistic coefficient how much it varied in a 10-shot string. It varies even more from rifle to rifle as shown in the 1:8 twist versus 1:10 twist comparison. Do not be surprised to find that a specific bullet produces a BC from your rifle that is quite a bit different from factory published figures. It does not mean that the factory was wrong or misleading, it only means that you tested at a different distance from a different rifle with a different load, just like happens with velocity. I have found that sometimes BC is poorer than a factory published figure and sometimes it is better.

During the course of using the System 89 for several months, I encountered some harsh conditions. One afternoon, the wind exceeded 20 mph. Tripods blew over with the radios. The SkyScreens blew over. I set them back up and put bean bags on the tripod legs to continue shooting. The SkyScreens whipped wildly in the wind, but in spite of this brutal treatment, the System 89 never missed a shot.

There is a learning curve with the system, but with a little use, things quickly smooth out. As I write this, the current price of the Oehler System 89 is $2,985. A buyer can spend more than that for a long-range riflescope. A scope goes on one rifle but the System 89 can be used with all your firearms.