Propellant Profiles

Alliant 20/28

column By: Randy Bimson | June, 22

When it comes to small-gauge shotguns I must admit that my collection is comprised of only two. Actually, one shotgun, a wonderfully built Beretta 471 side-by-side in 20 gauge, and an ever so delightful pair of Briley Companion 28-gauge tubes. The Briley tubes are set up to fit a 12-gauge Beretta 682 Gold Sporting and a Browning Superposed Superlight. The 471 does double duty as a field gun and more often than not, a skeet gun. The Briley Companion tubes turn the Beretta 682 Gold into a delightfully fun-to-shoot skeet gun and a well-used Browning Superlight into a very effective ruffed grouse and woodcock gun.

Before the “Great Ammunition Drought,” a lot of folks that loaded shotshells found there was little cost saving in reloading shotshells versus purchasing factory loads. While there was some truth to that, I had found then and even more so now, the availability of the various target and field loads for 20-gauge and especially 28-gauge shotshells to be very slim pickings in any of the many gun shops or sporting goods stores that I venture into. Consequently, I continue to load virtually all my target and field load 20- and 28-gauge shot shells.

With all the above in mind, I recall the opening passage of former Handloader contributing editor, Wallace Labisky’s 1972 “Propellant Profiles” article announcing the introduction of Hercules/Alliant Blue Dot powder: “Do handloaders have a genuine need for another shotshell powder?” Given the multitude of shotshell powders available then and now, the general consensus is likely no, yet Blue Dot has gone on to be a “must have” powder for many shotgunners and handgunners alike.

If you are an aficionado of the 20 and 28 gauge, this brings us to our topic of discussion. Alliant Powder’s 20/28 is unique in that it is designed specifically to provide the best performance in 20- and 28-gauge target and light field loads. It addresses two major problems typically associated with propellants used for loading 20- and 28-gauge shells. For one, 20/28 has been formulated to have the necessary bulk density, burning rate and energy content for use with the latest innovations in wad and hull designs, and two, to be the cleanest burning sub-gauge propellant available, according to Alliant.

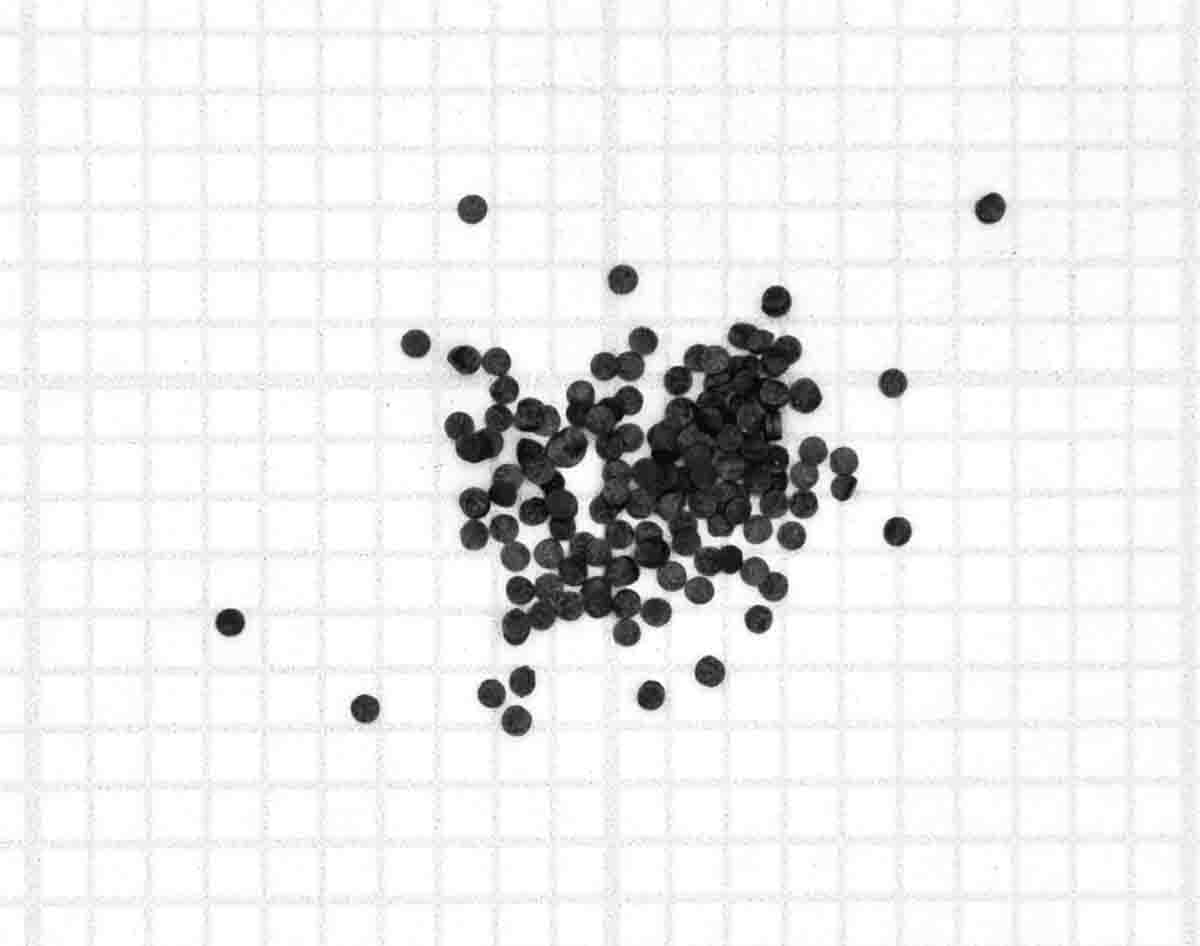

Introduced in 2007, 20/28 is, as might be expected from Alliant, a double-base propellant produced at the New River Energetics plant at Radford, Virginia. In the world of propellant powders, double-base infers that the principal energetic materials are nitrocellulose and nitroglycerine, which in this case Alliant does not state the exact proportions. The powder granules are a very consistent, non-perforated discs with a nominal diameter of 0.043 inch and thickness of 0.009 inch. Being that the formulation is optimized for use in relatively small capacity cases, it packs a considerable amount of energetic material into 1cc with a nominal bulk density of 0.65g/cc.

Viewed in the daylight, the color of the 20/28 granules is a medium gray. Unlike the Alliant “Dot” series of shotshell powders, 20/28 does not contain any colored granules to aid in identification. In recent burn rate charts Hodgdon Powder’s ballistic lab positions 20/28 as follows:

.jpg)

Note that relative burn rates are not a static number and may change over time or from one ballistic lab’s table to another, typically due to the lot-to-lot variations found in some propellants.

While the burn rate table makes it appear that 20/28 may have some crossover uses as a handgun propel-

lant, Alliant considers it a 20- and 28-gauge specific powder, with a secondary use for light 12-gauge, 2¾-ounce loads up to 1¼ ounces of shot. Neither Alliant nor the writer have at this time researched its use as a possible handgun propellant.

When I do my part, my 20-gauge Beretta 471 side by side is a deadly ruffed grouse and woodcock gun and as good a skeet gun as my shotgunning abilities require. A much-used 12-gauge Browning Superposed Superlight, along with the Briley 28-gauge tube set, makes for a great multi-purpose upland gun when on a trip that has me hunting CRP ground and open prairie for pheasants and sharptails one day, and ruffed grouse and woodcock the next day.

I have put tens of thousands of rounds through my 12-gauge Beretta 682 Gold Sporting, but a lot can be said for an afternoon of fun shooting skeet with the prior mentioned Briley 28-gauge tube set installed.

For the 28 gauge, I load 3⁄4 ounce of shot in Remington STS or Winchester AA hulls, just depending on what I have on hand. For the 20 gauge, I load 3⁄4-ounce and 1-ounce loads in 23⁄4-inch Remington STS or Winchester AA hulls as appropriate. Note that Alliant considers the original Winchester AA hull and the newer AA-HS hulls as interchangeable when used with 20/28 data.

I load all my 28- and 20-gauge shells on my workhorse Ponsness/ Warren 375 Du-O-Matic loader that has been cranking out bushel-baskets of shells since the mid-1970s. Note that for some unknown reason,

Alliant’s powder bushing chart for Ponsness/Warren does not list 20/28. Hornady and Ponsness/Warren powder and shot bushings are the same physical dimension. Hornady bushing numbers correspond to the inside diameter of the bushing (e.g., a number 327 bushing has an internal diameter of .327 inch). I either use the Hornady bushing and confirm the charge weight it throws in the 375 Du-O-Matic or extrapolate the internal diameter against my selection of Ponsness/Warren bushings.

Alliant 20/28 exhibits excellent “flow” characteristics when used with either shotshell loader powder bushings or in instances where I did not have the required bushing an RCBS Uniflow and a Neil Jones Custom Products benchrest-grade powder measure.

Unlike the fiber and card wads of days gone by, most, if not all, plastic wad columns commonly used today do not require specific wad pressures. I set the wad ram on my shotshell loaders to seat the wad firmly down on the powder charge and call it quits at that.

I have tested 20/28 from two different lots and have found it be extremely consistent in propellant charge to velocity comparisons. Regarding Alliant’s claim that 20/28 is the cleanest burning sub-gauge propellant available, that is somewhat subjective. I have found 20/28 at least as clean burning as any other propellants I have used for the same type of loads and readily apparent to be cleaner burning than some.

Made in the U.S. and available in 1-, 4- and 8-pound canisters, 20/28 is certainly worth a try for loading 20- and 28-gauge target and light field loads. I am very pleased with the performance and suspect readers will be as well.

.jpg)