Propellant Profiles

Vihtavuori N565

column By: R.H. VanDenberg, Jr. | October, 23

Vihtavuori manufactures one of the most extensive lines of propellant powders available for sporting and military small-arm cartridges. I think it is safe to say that its centerfire rifle propellants are Vihtavuori’s best-known product line among shooters in North America, particularly its High Energy N500 series.

The propellant we are delving into in this edition’s column is Vihtavuori’s N565 and it has an interesting history. Announced in 2017, and introduced to the reloading market in 2018, N565 was developed specifically as the optimum propellant for the 250-grain bullet 338 Lapua load used in military precision rifles. A number of the new cartridges purpose-built for use with long, heavy, high ballistic coefficient (BC) projectiles reap the benefits of using N565 as well. These include cartridges such as the 6mm Creedmoor, 6.5 Creedmoor, 6.5, 7mm, 300 PRC and 300 Norma. Other more traditional cartridges, such as the 6mm Remington, 243 Winchester, 6.5-284, 270 Winchester, 7mm Remington, 30-06 Springfield and 300 Winchester Magnum, just to name a few, also see an increase in performance when heavy-for-caliber bullets are partnered with N565 as the propellant.

Renowned ballistician and long-range shooter, Bryan Litz, won the 2021 Nightforce ELR (Extreme Long Range) Steel Challenge against a field of some 200 shooters engaging stationary and moving steel targets at ranges from 700 yards to 1.2 miles. Shooting a rifle built on the Barrett MRAD platform and chambered in 300 Norma Magnum, Litz’s winning load used N565 to launch a prototype 30-caliber, Berger 245-grain Hybrid Target bullet at 2,850 feet per second (fps).

Most handloaders who load centerfire rifle cartridges today are aware of the increased performance that temperature-stabilized propellants bring to the table. Well, N565 also incorporates improved hygroscopic stability. Of what importance is that you may ask? Hygroscopic stability refers to a propellant powder’s propensity to attract and hold water molecules. Just as temperature change can result in a change of chamber pressure and subsequently velocity, variations in moisture content change the burning rate of a powder and thereby chamber pressures and muzzle velocity as well. N500-series propellants normal moisture content is .6 percent or less. So, what difference does moisture content have in the real world?

In tests conducted by Vihtavuori’s ballistic laboratory, a powder sample was dried, losing about .5 percent of its weight. Cartridges were then loaded with the dried powder and fired in a pressure and velocity test barrel. Chamber pressures and muzzle velocities produced by these special cartridges were compared to those produced by cartridges loaded with untreated powder. The powder charge and bullet were of course the same in both sets of cartridges.

Comparing results showed chamber pressures increased from 320 MPa (46,412 psi) to 355 MPa (51,488 psi) with the dried powder, and the muzzle velocity increased accordingly from 770 m/s to 790 m/s (2,526 to 2,592 fps). This is only one example of one caliber and loading. The difference might be much higher depending on the cartridge and loading combinations.

I do recollect a phone conversation, during my time as director of Technical Affairs for The Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI), with a ballistic laboratory that was troubleshooting a problem they were having qualifying a particular lot of ammunition. They were replicating a previous production run of product using the same lots of powder and components as previously used, yet the pressure tests were coming back with abnormally high pressures. After a step-by-step analysis of their pressure test equipment and ammunition loading process and protocols, I happened to ask them if they had recently checked the calibration of the hydrometer in their powder storage area. The answer was no, they had never thought of that. It turned out the hydrometer was significantly out of calibration and the moisture content of the powder varied significantly from their required percentage. A few days later, the senior lab technician called me back and said that getting the propellant moisture content back in line with the norm also brought their pressures back in line. As a matter of interest, “reference ammunition” used to develop the cartridge-specific “assessments” that are the SAAMI standards that ballistic labs use to qualify their pressure/velocity equipment setups is conditioned for 72 hours at 70° ± 2°F (21.1° ± 1.1°C) with a relative humidity of 60 percent ± 5 percent before firing.

Last but not least, for those who are not big fans of frequently cleaning rifle barrels, N565 does contain a decoppering agent, but don’t get me wrong, you do eventually need to clean your barrel; it just gives you more shots between the inevitable fact that cleaning your barrel is still a must do.

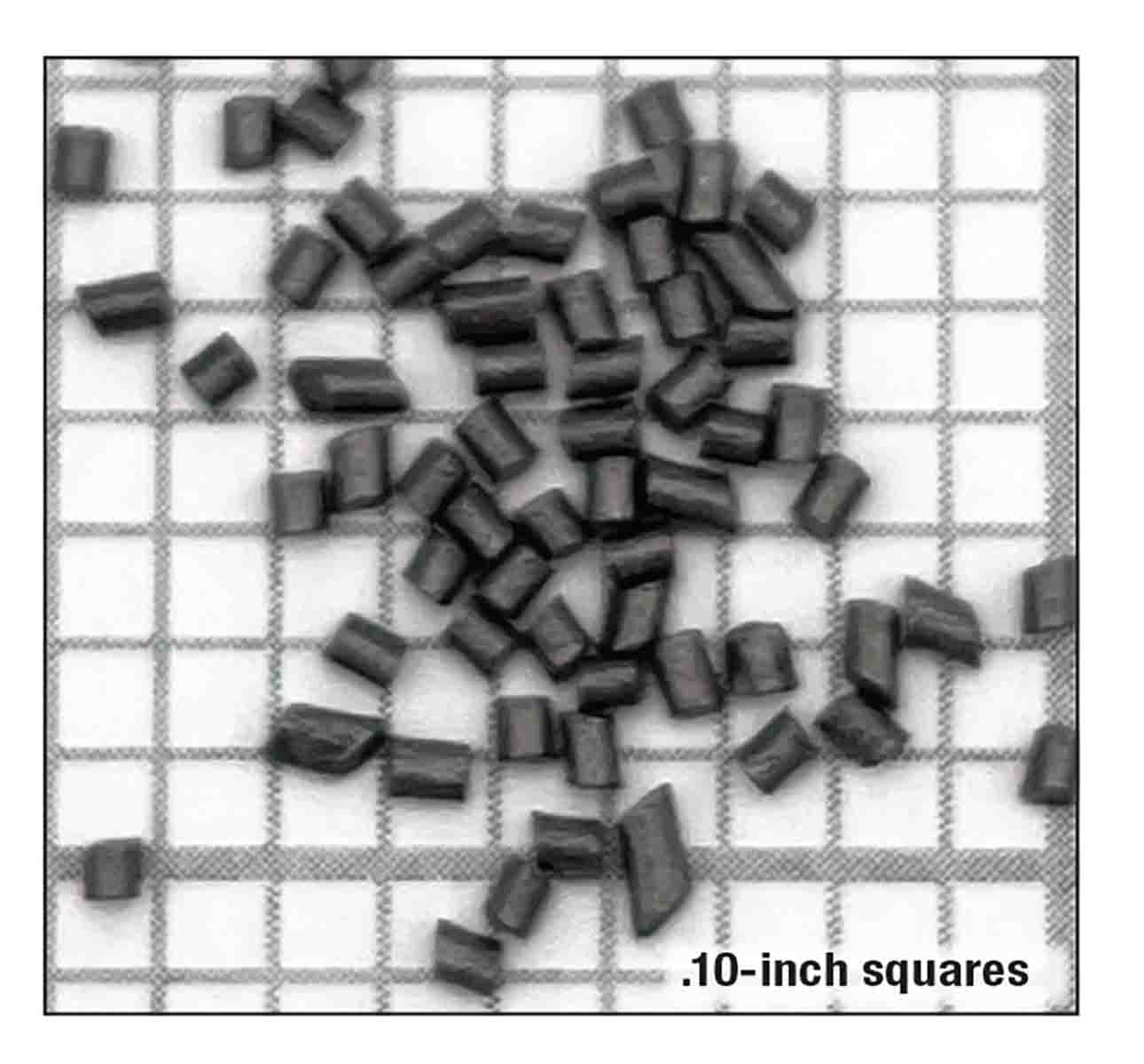

In the world of Vihtavuori, the burn rate of N565 sits about midway between the faster-burning N560 and their slower burning N568 and 570 powders. On the more all-inclusive Hodgdon burn rate chart where Alliant Reloder 25 ranks No. 152, N565 ranks No. 153 and Alliant Reloder 26 is No. 157.

At first blush, it would look like N565 is a very “specific use” slow-burning propellant, developed for use in large-capacity cartridges that take advantage of using heavy and long VLD-type projectiles. Cartridges like the 338 Lapua, 6.5, 7mm and 300 PRC, 300 and 338 Norma. It does, however, show a more versatile side delivering very good to best-in-class performance when combined with the more conventional heavy-weight bullets you may use for hunting loads in more mainstream cartridges many of us have rifles chambered for like the 6mm Remington, 243 Winchester, 6mm, 6.5 Creedmoor, 6.5x55, 6.5-284, 270 Winchester, 280 Remington, 7mm Remington Magnum, 30-06 Springfield, 300 Winchester and possibly many more.

In a world where heavy-for-caliber bullets, faster rifling twist rates, and slower burning propellants have become more and more the norm, N565 is a versatile propellant to have in your powder magazine. N565 is packaged in 1- and 8-pound canisters. Check out LoadData.com and Vihtavuori.com for more load data. Vihtavuori is constantly adding more cartridges and bullet-specific data to its online reloading data resource.

.jpg)