Reloader's Press

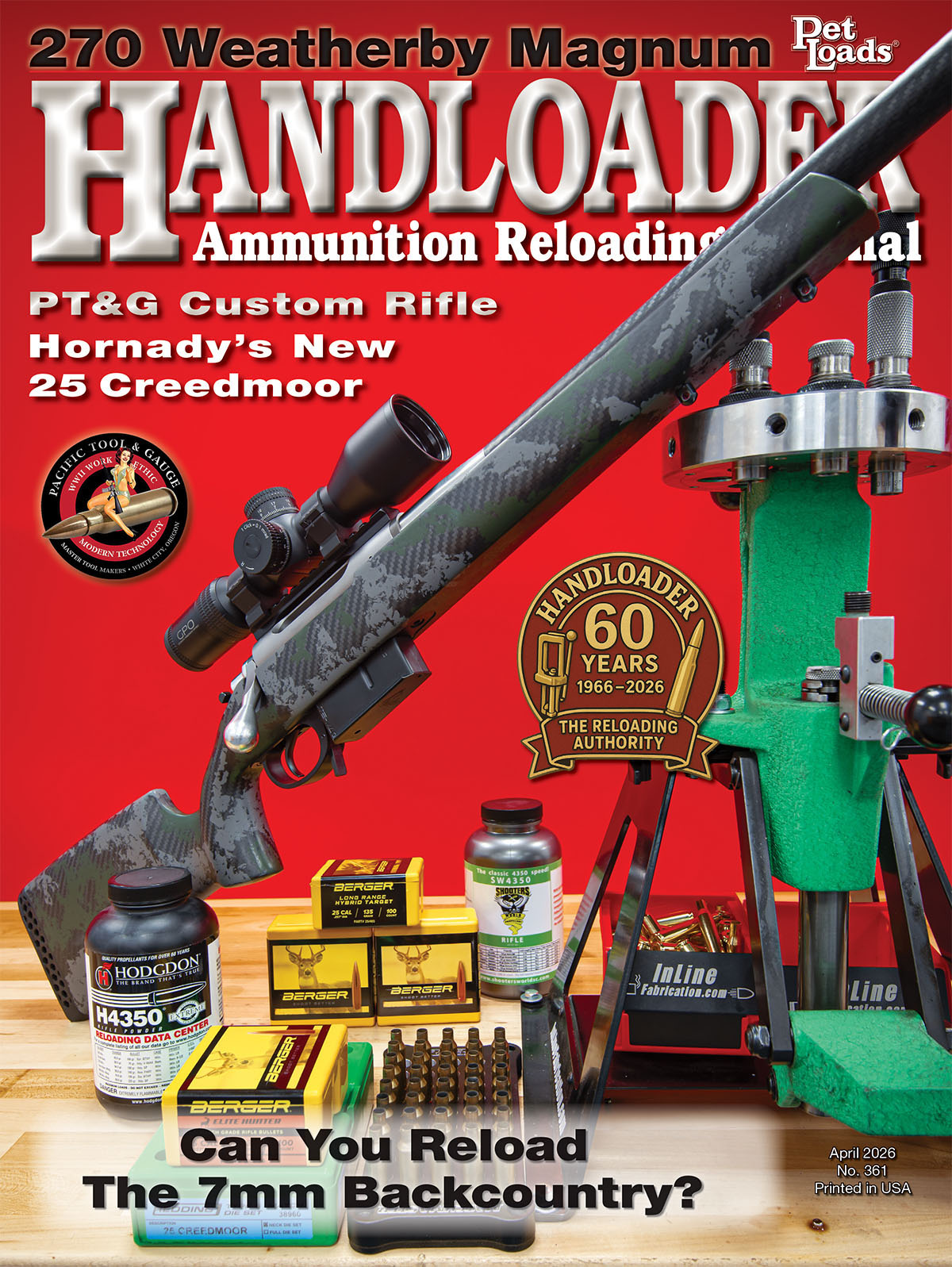

Pacific Tool & Gauge Custom Drakkar 25 Creedmoor

column By: Jeremiah Polacek | April, 26

Since the beginning, when man first started launching projectiles from barrels, there have been countless calibers that have risen and fallen. On occasion, we see these calibers fade a bit in popularity only to be revitalized later. We have seen this with the introduction of cartridges such as 27 Nosler and 6.8 Western. These cartridges also brought along updated bullet technology, with longer, sleeker projectiles with higher ballistic coefficients, which increased downrange performance. We are on the cusp of the very same thing happening in .25 caliber, thanks to Hornady’s introduction of the 25 Creedmoor and their new bullets to go along with it.

Being a fan of the quarter bore cartridges such as the 257 Roberts and the 25-06, I was naturally an early adopter of the 25 Creedmoor as well. Which was no easy task, it started out by contacting the good folks at Pacific Tool & Gauge (PT&G) to have a custom rifle chambered in the new cartridge. The timing was perfect and lined up with a factory tour that I had planned. This allowed me to oversee my rifle being built as well as gather a much greater understanding of everything they do at PT&G. Plus, I got to be one of the first people to have hands-on experience with some new technology that they are adding to rifles.

Seeing the entire facility in which they make nearly everything imaginable – from reamers, headspace gauges and reloading dies to full-on custom rifles – proved there was an impressive amount of machinery and hard-working individuals to meet production demands. Touring the facility allowed me to see their latest brand that just recently launched – a custom rifle manufacturer under the Bynuna name. Two custom rifles were set for production, one of which is the subject of this article and chambered in 25 Creedmoor. At this time, no production rifles were available, so it made sense to go directly to the folks who make the tooling to chamber the 25 Creedmoor and have them build a complete rifle. The highlight of this was being able to watch the entire rifle being built from start to finish and even taking it to a local range in Oregon and shooting it within hours of completion of the rifle.

Sadly, there is not enough space here to detail the factory tour or the finer details that went into these rifles. However, PT&G is the only company I know of that still handstones every reamer to put a perfectly polished cutting edge on it. They also showed me some new reamers that combine a finisher and a rougher into one tool, allowing for fewer tool changes and faster chamber reaming, all with a single reamer – a huge time saver. In addition, I got to implement and test some new products, such as their carbon-fiber-wrapped bolts, which slide through the raceways of my Drakkar action like silk on glass. At the time of this writing, they are the only company I am aware of that offers carbon-wrapped bolts. The reduction in friction and overall smoothness is impressive, even compared to my already smooth steel one-piece bolt in my 22 ARC, also built on a Drakkar action. The weight saving is another bonus.

After concluding the tour and wishing farewell to new and old friends, I went home with more projects, ideas and dreams than could be completed in a year. I decided to start with the new custom rifle in 25 Creedmoor, begin working up loads, and take the rifle into the field to see how the new technology performs in practical applications. At the time, the only load data I had access to was from Hornady, which was not yet released to the public. With some math and cross-referencing between the 6mm Creedmoor and the 6.5 Creedmoor, safe starting charges with a list of suitable powders were soon established. Just in time for a box of fresh bullets and cases to show up at my doorstep. I started with new, unfired Hornady cases that at the time were all that were available. Peterson Cartridge is now making 25 Creedmoor brass as well. I am sure more will soon follow. A set of Redding 25 Creedmoor Type S Bushing Dies was used to iron out any dings in the case necks from shipping and the proper neck tension was set to about .0015-.002 of an inch. An Area 419 Zero Reloading Press was used and cases were primed with Federal 210M primers using an RCBS Automatic Priming Tool. Two RCBS MatchMaster Powder dispensers calibrated with the same check weights were used to dispense proper powder charges. This ensured that the ammunition was as uniform and consistent as possible to give us a good representation of what the actual cartridge, load and rifle were capable of doing.

The initial load development produced some exceptional results, as seen in Table I. Overall, the rifle produced consistent sub-MOA results with a wide range of bullet and powder combinations. Some limited factory ammunition was also tested and produced consistent sub-MOA results. Factory ammunition has certainly come a long way in a relatively short amount of time. However, I also believe the Borerider chamber reamer and its design aids in the overall consistency of this rifle. A few loads

stood out as remarkably good, and a few groups were a little larger than I would like, but overall, the results are exceptional across the board. The overall average across all loads tested came to .81 inches, which makes this rifle a true sub-MOA rifle across 25 different loads. It is one thing to have a rifle that is sub MOA with a good load, but entirely different to have sub-MOA performance across 25 different loads tested and a total of 125 rounds on paper. The rifle also showed minimal point-of-impact shifts when changing bullets or powders. The largest jump in point of impact was when Barnes LRX bullets were used, likely due to their solid copper construction. After testing was completed, there was a 2.50-inch group on the target backer, which means across 25 different loads and 125 rounds, the rifle produced a 2.50-inch group. Imagine what it could do with one really good load!

This was also my first experience with BSF Barrels and I was pleasantly surprised with the performance. The barrel is no doubt capable of delivering fine accuracy when paired with a proper action and good gunsmithing. It is also nice to have an alternative to Proof Research for carbon barrels, as for a while, if you wanted an accurate, high-quality carbon barrel, they had the market cornered. Now we have another option that appears just as good or perhaps even better than Proof Research.

Since the time that the load development was conducted on this rifle it has also been shot at distances out to 1,000 yards, with several of the better loads in the table, edging out my 6.5 Creedmoor in both wind drift and bullet drop at 1,000 yards. However, my 6.5 Creedmoor only has a 22 inch barrel so it’s not an apples-to-apples comparison but the ballistics of the 25 Creedmoor on paper do outperform the 6.5 Creedmoor with many loads. The rifle performed very well under field-style shooting conditions and has been a pleasure to pack around thanks to its light weight of about 7 1⁄2 pounds with an optic.

Overall, I am excited to see what will happen with .25-caliber cartridges in the future, and I believe that the 25 Creedmoor was just the shot in the arm this caliber needed to get folks talking about how great the quarter-bore caliber can be on game as well as ringing steel at the range.

If you would like to watch the accompanying video to this article, check out the video titled “25 Creedmoor Load Development” on our YouTube channel Handloader TV.

.jpg)