Reloading the 7mm Backcountry

~ With Extra Care and Caution, You Can ~

feature By: Lane Pearce | April, 26

An old cigarette ad from years ago targeting women smokers touted, “You’ve come a long way, baby!” The same ditty can be used to describe the evolution of munitions and firearms. For about 150 years now, most firearms have fired “fixed” ammunition, i.e., the primer, propellant and bullet are assembled into a typically copper or copper alloy (brass) cartridge case.

During the previous several hundred years, you poured a measure of loose gunpowder into the rifle barrel or multi-chambered, rotating cylinder; then inserted a patched ball or several balls atop the powder; and, finally, carefully pressed one or several small percussion caps onto the nipple(s) that were screwed into the firearm or cylinder breech. Pull the trigger, the hammer dropped and crushed the cap, igniting the powder charge. Pressures did not exceed fifteen to twenty thousand pounds per square inch (psi).

Over the last century or so, the ballistic performance of our firearms has continued to improve. Modern, high-pressure, smokeless munitions are now common fare. Premium bullets, temperature-stable propellants, and ‘clean’, i.e., no rust-causing primers, are almost universally used.

However, often in times of conflict, steel cases were implemented because copper was more expensive. Commercial or military ammunition loaded in steel cases are usually coated with a protective film to help prevent rust, assure smooth feeding and to avoid damaging the firearm. In recent times, aluminum alloy and even polymer cases have been developed because they’re also less expensive. Typically, non-brass cases are suitable for firing only once, i.e., they aren’t intended to be reloadable. In fact, steel and aluminum cases are often Berdan-primed, which decidedly dissuades reloading them.

A few years ago, SIG Sauer introduced the 277 FURY rifle cartridge. It features a steel case head that is securely attached and sealed to the usual brass case body. Developed for the military, it hasn’t achieved much commercial appeal and isn’t readily reloadable. Actually, a screw-on, steel case head cartridge was introduced more than sixty years ago. The steelhead round offered by the O’Conner Rifle Ranch never became popular with hobbyist handloaders and soon disappeared.

Metallurgical and design technologies have also improved dramatically during this era, resulting in more versatile, reliable and much stronger firearms. The limiting factor to further improving small-arms performance is now the once-revolutionary brass cartridge case. Rifle maximum pressures are typically capped at 65,000 psi, while magnum handgun maximum average pressures (MAP) range from 35,000 to 55,000 psi. For many, many years now, these extraordinary levels of performance were quite adequate for shooters. Apparently, not any longer.

Federal recently announced the 7mm Backcountry rifle cartridge that launches a 170-grain bullet from a 20-inch barrel at 3,000+ feet per second (fps). Now, anyone with modest ballistic smarts knows a 24- to 26-inch barrel is needed to achieve that velocity, right?!?! Well, not if you jack the allowed MAP up approximately 23 percent to 80,000 psi! So, how’s that possible if the brass cartridge case material properties can’t safely withstand much more than 65,000 psi?

Simple. Federal’s engineers developed a stronger steel “Peak Alloy”cartridge case that can handle the increased pressure to safely achieve the enhanced ballistic performance. Of course, an expected question immediately came from the hobbyist handloader, “Can I reload it?” After much effort involving several companies in the industry, the answer is a qualified “With extra care and caution, you CAN safely reload the 7mm Backcountry cases – but only the premium nickel ones!”

Federal has demonstrated just that. Of course, it’s well beyond any previous reloading experience, so negative (imagined or real) comments quickly surfaced. I also questioned the practicality of promoting the new, high-performance round as reloadable. My thoughts were, if you can afford several thousand dollars for a new rifle, optic, and an almost mandatory suppressor to outfit for a sheep hunt costing many more thousands of dollars, surely you can afford to buy several boxes of proven safe and reliable factory ammunition. This cartridge was not intended for the Precision Rifle Series (PRS) circuit or for shooting hundreds of rounds yearly at varmints.

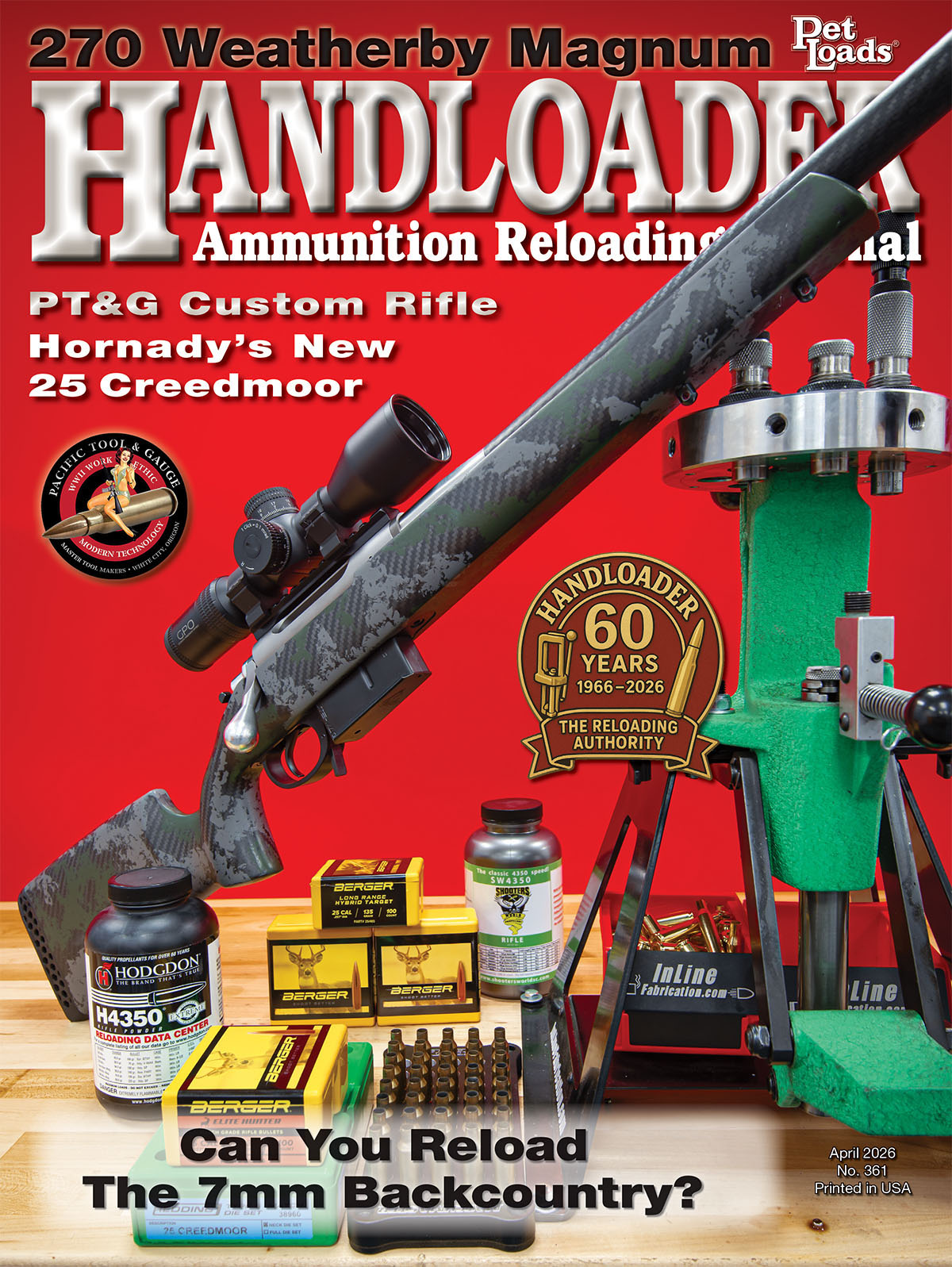

As an engineer, I had my doubts, but eventually the challenge to overcome them and find out for myself prevailed. Putting aside my preconceived notions and possibly unfounded biases, I purchased a Weatherby rifle, compared notes with industry friends, asked RCBS for dies and Federal for samples of factory ammunition, and fired cases. Hodgdon shared some initial load data they had developed to get me started.

RCBS had performed the initial tooling development. They shared a few lessons learned so I could avoid the same problems they’d encountered:

- You must use a heavy-duty, single-stage press like the Rock Chucker Supreme.

- Adjust the full-length sizer die a quarter turn past the point that it bumps the shell holder, because reducing the case head diameter takes extra force.

- Don’t bother trying to trim or deburr/chamfer the case mouth with the usual reloading tools because the case material is too hard.

- You must lube the inside of the case neck to avoid damaging it when the expander ball is pulled back through and leave the residual lube to ease seating the bullet.

- An extra die is required to slightly flare the case mouth so it doesn’t shave the bullet jacket when it’s seated.

- The seater die must be adjusted so it will slightly taper crimp the case mouth to remove the flare.

My gunsmith, Isaac Gallagher, ordered a Weatherby Model 307 HUSH rifle. It features a 20-inch barrel with an added 2-inch muzzle brake, composite stock, detachable Magpul 5-round magazine, adjustable trigger and a 3-shot, 1 MOA accuracy guarantee with premium factory ammunition. As you can see from the table, the velocity claims are valid even with several of my test loads. I experienced no surprises while firing about a hundred rounds during several range sessions. When the bullet exits the muzzle, the concussion is quite noticeable. I ordered a Silencer Central Banish Backcountry suppressor and replaced the brake.

With all of this assistance and planning, what could go wrong? Of course, best laid plans are often soon undone. Federal sent me samples of two factory loads. A 170-grain Terminal Ascent and a 168-grain Barnes LRX. They both delivered 3,000+ fps as advertised. However, Hodgdon (of which RCBS is now a subsidiary) decided caution was the best business decision and went ‘dark’. Redding and Hornady have also opted to skip the party for now. Primarily because almost no one has inquired about ordering dies. Lyman told me they were going to ‘wait and see’ if the 7mm Backcountry gained interest. So, I wasn’t going to get any dies, and my industry sources for reloading advice had been severely curtailed.

Time to improvise. Obviously, the first two lessons learned were not important, but the last four proved to be quite true.

I retrieved a Redding 7mm RSAUM neck sizing die fitted with a carbide expander button. After verifying the once-fired premium cases would easily chamber in the Weatherby M307 rifle, I proceeded to reload 10 cases. I consulted with another one of my industry reloading mentors, who was still communicating with me, and concluded that using maximum charges of 280 Ackley Improved load data with 175-grain Fusion bullets was a good starting point.

Initially, I reloaded 24 cases at least three times, fired 40 factory loads, and approximately 100 handloads with seven candidate propellants. I experienced a half dozen or so cases stuck in the chamber after firing. The most occurred after reloading them three times. I could not release any load recipes until Federal tested my handloads in their lab and deemed them safe.

I still have my eyesight, and my fingers and hands are all intact. Recoil is quite tolerable. Accuracy is as expected. Some loads grouped better than others. My limited testing was only intended to demonstrate the case could be reloaded a FEW times and there are several propellant options that will SAFELY approximate factory velocities. The charges listed in the chart are MAXIMUM loads and should be reduced appropriately to start. I realize the data is sparse and, hopefully, if interest in the new round warrants it, one or more firms will change their mind and offer dies and reliable load data.

Just like the significant changes in munitions I described earlier, the steel alloy cartridge case is surely a significant step in improved ballistic performance. Copper/brass cases introduced reloading. Switching from black powder to modern smokeless, high-energy propellants came with a quick but often costly learning curve. I’m sure handloaders and firearms were hurt/damaged until the safe and proper “how-to” lessons were learned. The same potential “accidents” will inevitably occur with reloading the 7mm Backcountry.

My endeavors and the support from Federal are intended to minimize the incident rate. Federal tells me that this will not be the last “new” round to be introduced, operating at extraordinarily higher pressures in a Peak alloy case.

In summary, reloading this new round is relatively straightforward – if you strictly follow the few points below:

- Neck size cases fired in your rifle ONLY! Be sure to lube the case neck inside and out before sizing. Leave the lube inside the neck – seating the bullet later will be easier to accomplish.

- As you recycle your cases, keep a count and reload them – only the fully nickel-plated premium cases – no more than three times. Just like with brass cases fired in the same rifle and only neck-sized when reloaded, the round will likely chamber a bit more snugly each time. With a brass case, you can easily remedy that by full-length resizing. Not so with these new cases, likely because no one has yet offered full-length or body sizing dies. We don’t know enough about reusing them yet to recommend reloading them more than a few times for now.

- You must slightly flare the case mouth to preclude the inside edge from digging into the bullet/jacket when it’s seated. To complicate this step, you MUST NOT chamfer the case mouth because doing so will compromise the protective nickel plating on the steel case. Each case should be measured first to ensure they aren’t too long and second, group those with the same length +/- 0.001 inch in separate batches. You need to flare every mouth similarly, which means you’ll have to adjust a special tapered expander die as you process each case.

Don’t think this step is not needed if you’re loading boat-tail or solid copper alloy bullets. Firsthand experience witnessed the jacket/copper surface peeling up the case mouth as I forced the bullet into place. Trashed that round…..and the next one(s) I forced…. - The seater die must be machined with a taper crimp feature to “iron out” the flare when the bullet is fully seated to the desired cartridge overall length.

See, I told you it could be done – the process is just a bit different than the way we’ve reloaded every other rifle cartridge with a conventional brass case.

Special Note: A statement of caution based on my engineering background and handloading experience. DO NOT anneal Peak alloy case necks to attempt to extend case life. Heat treating and tempering the exotic steel alloy is NOT a recommended activity for ANY handloader. The processes and procedures many of us are familiar with and have performed with brass cartridge cases are NOT appropriate for 7mm Backcountry’s Peak alloy steel cases. Federal recommends reloading them no more than three times. I say do so only if the force required to pull the expander plug through the case neck seems to be almost the same as that experienced in the previous reloading cycle. If an incipient crack forms when the round is fired or reloaded, it will propagate when you load/fire it again. The chamber seal will be compromised, and super-hot, HIGH-pressure propellant gas will vent and may damage the rifle and injure the shooter. DON’T DO IT JUST ONE MORE TIME!!! Crush the case neck and toss it in the trash. Steel is biodegradable.

[Editor’s Note: the Lee Precision 7mm Backcountry die set was not available at the time of this writing. However, as of publication date it is available and works as long as an optional factory crimp die and case flaring die is used in conjunction with the die set. The research and development for handloading this cartridge is still ongoing. Use extreme caution when reloading the 7mm Backcountry.]

.jpg)