John Linebaugh Tribute Gun by RW Grip Frames

Classic Meets Modern

feature By: Jeff “Tank” Hoover | February, 26

John’s early experiments involved turbocharging the humble 45 Colt in El Dorado and Seville sixguns. As the grand cartridge is my favorite, I quickly became a Linebaugh fan without ever meeting him. In those early days, John claimed velocities from his custom six-shot revolvers shooting 260-grain bullets, both cast and jacketed, of over 1,700 feet per second (fps); 310-grain bullets 1,565 fps; 325-grain bullets 1,600 fps and 385-grain bullets 1,300 fps. This ability was possible by enlarging the cylinder window for a custom oversized cylinder he made.

Not everyone can do what Ronnie Wells did, because he has the skill set necessary for building guns, as he’s worked on them in his grandfather’s gun shop since he was 6 years old. As time progressed, the youngster progressed to running machinery in the shop. Ronnie is an accomplished CNC Control and Machine Tool Design Engineer today.

As a matter of fact, Ronnie rebuilt and reprogrammed the machinery he purchased used to manufacture gun parts of his own making. For years, he put these skills to work at various jobs, including working on a pacemaker for St Jude Hospital, missile and rocket engines for the DOD, aircraft and top fuel racing cars and a smidgen of oil tools work.

Ronnie’s family moved to the Houston, Texas, area in 1969, when his dad wished to work in the space program but became part of the Hi-Lo Auto Supply. Ronnie continued perfecting his machining skills by building engine-driven skateboards using chainsaw engines. If it ran on gasoline, Ronnie could make it run faster.

Ronnie has retired from the race car scene and said, “It’s Ronnie time now, time to have some fun!” Lucky for us, his idea of fun is making guns. Around this time, his mentor and friend, John Linebaugh, prematurely died of a heart attack while working in his shop.

Ronnie decided right then that his first big project would be building tribute guns honoring John Linebaugh, limited to 100 guns. The guns are offered in 45 Colt, the first cartridge John experimented with, and of course, the 475 Linebaugh and 500 Linebaugh, which bear his name.

The cylinder is the heart and soul of any gun. This one is line-bored, meaning the throats are perfectly centered to the forcing cone/barrel. There’s no bullet scraping as it enters the forcing cone. This ensures accuracy and good bullet alignment with the rifling. The five-shot cylinder provides thicker/stronger chamber walls made of heat-treated 17-4PH steel.

The cylinder throats are reamed .453 inch, which is perfect for shooting cast bullets, so the oversized slugs will better seal the barrel and engage the rifling for top accuracy. Since the gun is marked “45 LC CAL–H.P.,” for high pressure, the chambers are bored to accommodate 454 Casull cartridges, making it capable of firing both Casull and hotly loaded 45 Colt loads with longer, heavier bullets for added versatility.

The ejector rod housing, trigger and hammer pins, and base-pin latch also have the same copperish hue from heat treating. This beautifully accents the high polish bluing of the barrel and cylinder frame. Last but not least, an oversized Keith No. 5 base pin is used for looks and function, which of course, was made by Ronnie.

The hammer is 4140 carbon steel, and the trigger is 01 tool steel. The trigger is longer and has the same contour as the inside of the trigger guard, creating a natural trigger stop. Both are color cased, further adding to the traditional look of the gun. The ejector rod button is skeletonized using wire EDM, making your finger sink into the skeletonized button. This provides smooth operation when working the rod to expel spent brass in classic single-action style.

My name is stamped inside the brass grip-frame for some future, confused archeologist to discover hundreds of years from now.

Ronnie got tired and frustrated waiting around for custom triggers and hammers from his usual vendors, so he did the only natural thing: he made his own, the way he wanted them made. This is why he built his own hammer and trigger. Cocking the hammer lets you know this is a custom gun of the highest quality, as every moving part meshes smoothly and tightly.

The heavy-profiled Douglas barrel is 5.5 inches long, target crowned, with a 1:16 twist. This allows it to stabilize the heaviest of bullets. The front sight is dovetailed with two set screws on either side of the high-tech, red fiber optic front sight, which locks the sight in place. The rear sight is machined into the cylinder frame top strap with a facing edge serrated and angled to prevent any glare.

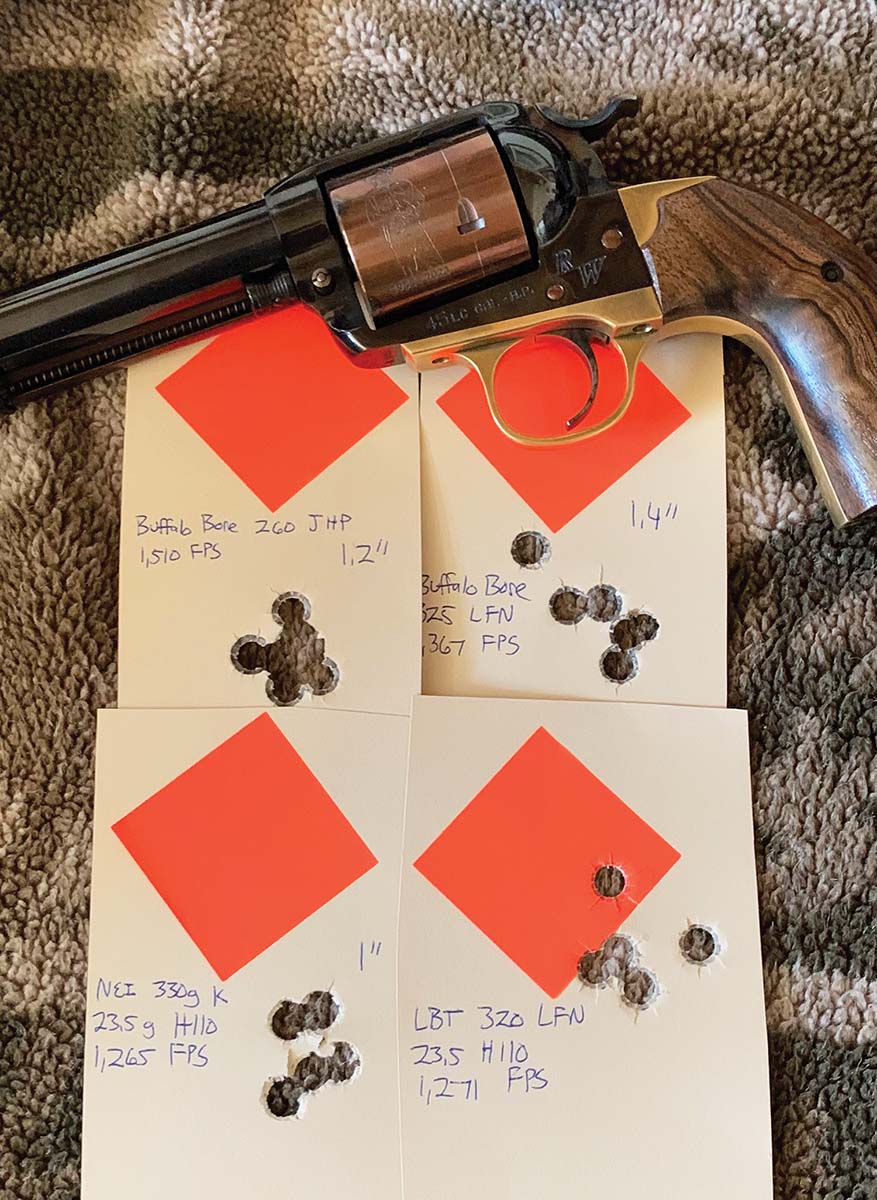

Since this is a John Linebaugh Tribute gun, it only makes sense to test his pet loads in the gun, right? Shooting was done at 25 yards using a Ransom Multi Cal Steady Rest. All bullets were cast for the 45 Colt handloads and then polymer powder coated. Bullets were sized to .452 inches with a Lee Automatic Processing Press and sizing bushing. Alloy was an alchemist’s mix of lead shot, clip-on wheel weights, roof sheathing and a small chunk of tin. The alloy approximates the Lyman No. 2 mixture, with a hardness of 15-16 Brinell Hardness Number (BHN).

The first load is the one I already mentioned. I used 8.0 grains of Winchester 231 with a Lyman Keith 454424 (which happens to be my favorite cast bullet of all time) in 45 Colt brass. I had several other handloads and some factory fodder to shoot for testing as well.

Velocity is just over 900 fps from my John Linebaugh Tribute gun with groups running just over 1 to 11⁄2 inches. As mentioned, this is my everyday pet load and is a pleasure to shoot.

John stated he used only three loads for his 45 Colt cartridges in his large-framed Rugers. The above 8.0 grain load of 231, followed by 13.0 grains of Hodgdon HS-6 with 260-grain Keith’s and 310/320 cast bullets and last, his heavy load of 24.0 grains of either H-110or Winchester 296 (which are the same powder) with 260 Keiths or 310/320 cast bullets.

The 260-grain Keith, when loaded over 13.0 grains of HS-6, clocked out at 1,056 fps with groups running under 2 inches. My lead bullet (LBT) 320-grain long flatnose gas checked went just over 1,000 fps and averaged just over 1.5 inches.

The 24.0 grains of W-296 with a CCI 350 magnum primer pushed the 260-grain Keith to 1,289 fps, with groups running just under 2 inches. The LBT 320-grain slugs averaged 1,287 fps, running around 1.5 inches.

The 454 Casull cases were topped off with 31 grains of W-296, sparked by CCI 450 small rifle magnum primers. I used the MP Molds 325-grain GC “Ruger Only” mold. This load runs a whopping 1,531 fps and shoots as well as one can hold.

Factory loads from Buffalo Bore Ammunition using their 3A/20 Outdoorsman load, consisting of a 360-grain hard-cast LBT LFN, clocking at 1,367 fps. They shot very well with five shots running about 1.5 inches. I’ve found Buffalo Bore ammunition to be a good test medium for guns, as their loads always seem to run consistently and usually are a good indicator of what an untested gun is capable of. I also shot Buffalo Bore’s 260-grain jacketed hollowpoint, 3G/20. Velocity was 1,510 fps with groups running under an inch for five shots.

Ronnie Wells was a friend of John Linebaugh, and it’s only fitting for him to make a tribute gun honoring John for the many innovations he shared with the sixgun world, namely, showing us just how far we can push big bore, easy carrying sixguns, powerful enough to take anything on the planet.

Ronnie Wells is a name you will be hearing a lot about for his brilliant designs when building custom guns or parts, and his use of automation for making them. I could not be more proud of having serial number “JLT # 001” in a five-shot single action, the way John started experimenting with his high-pressure loads, showing us what the grand old 45 Colt is capable of. This led sixgunners down the path to his bigger bores, namely the 475 and 500 Linebaugh cartridges. From your dedicated fans, John, this one’s for you. You’ll always be remembered.

.jpg)

.jpg)