Propellant Profiles

Nobel Sport Vectan Ba9

column By: Rob Behr | February, 26

What I eventually received were samples of Nobel Sport Vectan Ba9½ and Vectan Ba9. It was a very nice surprise. Nobel Sport propellants enjoy an enviable reputation in Europe, but they are not commonly available in the United States. Now that Shooters World has become the importer and distributor of these French-made powders, American handloaders will have an opportunity to explore the unique capabilities of these excellent propellants.

The Vectan burn rate chart includes five powders with the Ba prefix: Ba10, Ba9½, Ba9, Ba7½, and Ba6½. These are listed in burn rate order, with Ba10 being very fast, somewhere in the neighborhood of Alliant Bullseye, and the much slower Ba6½ running close to Winchester 296. I chose to start with Ba9 because its burn range is close to that old pistol caliber workhorse: Alliant Unique.

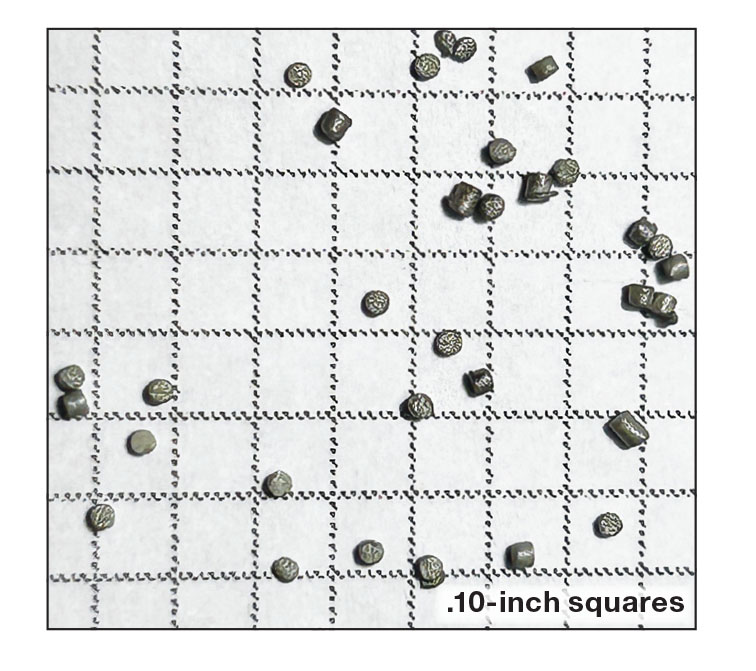

Physical Characteristics

geometry (flake shaped), Ba9 is a relatively large-grained, single-base propellant. This shape provides a case-filling bulk density of approximately .638g/cc. The powder grains are universally light gray in color, with no reflective surfaces.

Temperature Stability Testing

Using Vectan’s stated maximum load, I set aside 15 rounds of 9mm Luger made with Montana Gold 115- grain full metal jacket (FMJ) bullets and 5.6-grains of Ba9. These were frozen overnight at -22° Fahrenheit in an insulated container. An identical batch was prepared for comparison testing at ambient temperature.

I strongly suspected that Vectan Ba9 was going to perform well because of its single-base chemistry. Double-base propellants can struggle with temperature stability because the two energetic materials, nitrocellulose and nitroglycerine, react differently when exposed to extremely high and especially extremely low temperatures.

Using a SIG 320 Compact, I fired slowly to keep chamber temperatures as low as possible and only loaded two or three rounds at a time. This allowed the others to stay in the cooler for as long as possible, producing an average velocity of 1,126 feet per second (fps). Ambienttemperature testing at about 83° Fahrenheit produced an average velocity of 1,127 fps. If you live in Alaska or anywhere with very cold winters, this is a powder worthy of consideration.

Powder Positional Testing

Powder migration within a cartridge can cause surprisingly high variations in pressure. Ballistic lab testing procedures recognize this and go to great pains to orient the powder, as much as possible, toward the primer. This position produces the highest pressure for a given powder/bullet combination. The lowest pressure is created with the powder oriented against or near the bullet. The intermediate position, where the propellant is evenly distributed throughout the length of the case, is the one most commonly found during real-world shooting. The potential for these changes in pressure is why loads that approximate 100 percent case fill are typically the most consistent. They do not allow powder migration within the cartridge.

There are two common culprits for powder position problems in handguns. Both the 38 Special and the 45 Colt use voluminous cases and operate at very low maximum pressures. In the instance of the 45 Colt, the maximum pressure is only 14,000 pounds per square inch (psi). Typically, these cartridges are loaded with small charges of relatively fast powders in order to stay below SAAMI (Sporting Arms and Ammunition Manufacturers’ Institute) maximums. This type of load can produce positionally caused extremes of hundreds of feet per second, and sometimes lose so much pressure that the bullet is left stuck in the barrel.

I loaded new 45 Colt brass with 250-grain lead Lyman Silver Star bullets and the published minimum load of 7.1 grains of Ba9. Aiming the pistol nearly straight down and shaking it before slowly raising it to eye level produced an average of 472 fps. Aiming the pistol nearly straight up and then carefully lowering it to eye level produced an average velocity of 601 fps. The intermediate level position produced an average of 532 fps. This is actually pretty good performance for a powder in the 45 Colt. With the testing controls stacked heavily against it, Ba9 only suffered a 13 percent loss of velocity. This can be attributed to Ba9’s low bulk density and its very favorable burning rate for this cartridge.

Clean Burning

Picking on the 45 Colt again, I decided to use it as my arbitrary standard for Ba9’s ease of cleaning. Lower ignition pressures tend to bring out the worst in powder fouling, often leaving a greasy residue or grains of partially burned propellant. Again, Ba9 won out against long odds. My borescope did not reveal any unburned powder in the bore. The cylinder gap and forcing cone were clean. A dry patch run tightly through the bore left so little fouling that I had to do it again to begin to get a light grey smudge on the patch. A couple of passes with Hoppe’s No. 9 and a dry patch left the bore with no evidence that more than 50 rounds had been fired through my replica 1873 Colt.

The Takeaway

Nobel Sport Vectan Ba9 is too fast-burning to produce absolute top velocities in modern cartridges. What it does is offer extremely consistent loads in terms of velocity and pressure, even under adverse testing conditions. It ran well in the 9mm Luger and especially well in one of my 1911 45 ACP pistols. Overall, I think this powder could provide match-grade consistency in most larger handgun cartridges.

American handloaders owe Shooters World a round of applause for introducing this great powder to the United States.

.jpg)